46~90 item / All 106 items

Displayed results

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us OnlineBefore making an inquiry

Download PDF46~90 item / All 106 items

We would like to introduce a case of "earthquake recovery work" and "floor sinking correction work" carried out at a large pachinko parlor located in Fukushima Prefecture. In this case, the floor inside the store had significantly sunk due to consolidation settlement and the impact of the Great East Japan Earthquake. The tilt of the floor caused discomfort while walking inside the store. An up-con method that could be corrected during the night while the store was closed was adopted, and our company conducted the sinking correction work. 【Case Overview】 ■ Construction Area: Approximately 700m2 ■ Maximum Settlement Amount: 161mm ■ Area: Fukushima Prefecture ■ Construction Period: Continuous 4 nights *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is a case study of "disaster recovery construction" and "floor sinking correction work" conducted at a toy retail store and an electronics retail store in Fukushima Prefecture. Due to the impact of the Great East Japan Earthquake, the floor inside the toy retail store sank significantly. As a result of the floor sinking, gaps were observed between the floor and walls, as well as between the walls and ceiling. To address this, an up-con method that could be implemented during nighttime while the store was closed was adopted, and our company carried out the correction work. Additionally, since voids were also observed beneath the floor, void filling work was conducted by injecting polyurethane resin into the gaps. [Case Overview] ■ Construction Area: Approximately 2,300m2 ■ Maximum Sinking Amount: 144mm ■ Area: Fukushima Prefecture ■ Construction Period: Continuous 11 nights (2012) *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Here is an example of "settlement correction work" carried out at a drugstore in Niigata Prefecture. In this case, the store's floor had sagged due to settlement. At the time of the store renovation, they wanted to correct the floor to be level, so they chose our Upcon method. The construction area was approximately 1500m2. Using the concrete replacement method, a project that typically takes one month was completed in just four days. (Settlement amount approximately 100mm) 【Case Summary】 ■ Construction Area: Approximately 1500m2 ■ Maximum Settlement Amount: Approximately 100mm ■ Area: Drugstore in Niigata Prefecture ■ Construction Period: 4 days *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a case where "disaster recovery work" and "floor sinking correction work" were carried out at a game center located along a national highway in Niigata Prefecture. In this case, part of the floor inside the store sank due to the impact of the Chuetsu earthquake. Therefore, the company was requested to correct the sinking because it could be done in a short period of time. The sinking correction was performed using the Upcon method with rigid polyurethane foam. The work was completed in one day. 【Case Overview】 ■ Area of sinking correction: Approximately 83m2 ■ Maximum sinking amount: -77mm ■ Planned correction value: Within 16mm ■ Area: Niigata Prefecture ■ Construction period: 1 day *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a case of "floor deflection correction" and "subsidence correction work" carried out at a certain supermarket in Ibaraki Prefecture. In this case, the customer was troubled by the floor inside the store being deflected due to subsidence. Using the Upcon method, the work was conducted only at night, with minimal impact on business. The construction was completed in a short period of 2 days without any store closure. 【Case Overview】 ■ Construction Area: Approximately 450m2 ■ Maximum Subsidence: Approximately 83mm ■ Area: Ibaraki Prefecture ■ Construction Period: 2 days *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a case of settlement correction implemented at a warehouse in Fukushima Prefecture. Due to the effects of the Great East Japan Earthquake that occurred in 2011, gradual settlement progressed over the years. After a few years, floor sagging and tilting began to occur inside the warehouse, and inclinations also developed in the rack installation areas. This caused issues such as the forklift forks not fitting properly, leading to "longer loading and unloading times," which disrupted operations and caused difficulties. In this project, we adopted the Upcon method, which allows for construction without moving heavy racks in a short construction period. We were able to correct an area of approximately 1,250 m² in just four days (with a maximum settlement of about 78 mm). [Case Overview] - Construction Area: Approximately 1,250 m² - Maximum Settlement: 78 mm - Location: Warehouse in Fukushima Prefecture - Construction Period: 4 days *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a case of "void filling work" conducted at a certain food warehouse in Kanagawa Prefecture. Using the Upcon method, which allows for the filling of voids that developed under the floor with polyurethane resin in a short period, we corrected a maximum void of 270mm (with a construction area of approximately 171m2) in just three days. After the resin filling, we checked the filling condition with a CCD camera and used non-shrink mortar to seal the injection holes. 【Case Overview】 ■ Construction Area: Approximately 171m2 ■ Maximum Void Size: 270mm ■ Location: A certain food warehouse in Kanagawa Prefecture ■ Construction Period: 3 days *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a case of "void filling work" carried out at a logistics warehouse handling medical supplies located in Gifu Prefecture. Due to the effects of ground subsidence, voids had formed under the floor, which were filled with polyurethane resin. Compared to conventional concrete replacement methods, this construction generates almost no dust or debris, allowing for work to be done without moving the cargo. 【Case Overview】 ■ Area: Gifu Prefecture ■ Construction Period: 2 days *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Here is an example of "floor level adjustment work" carried out at a logistics center in Kumamoto Prefecture. Due to the impact of the Kumamoto earthquake, floor subsidence occurred. As a result of the subsidence, a height difference was created, making it difficult for forklifts to operate for transporting goods. Using two trucks loaded with Upcon equipment, we quickly corrected the subsidence. Immediately after the completion of the work, forklift operations became possible. 【Case Overview】 ■ Construction Area: Approximately 1798.5m2 ■ Maximum Subsidence: 107mm ■ Area: Logistics center in Kumamoto Prefecture ■ Construction Period: 6 days *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a case of "floor sinking correction work" conducted at a large product storage warehouse in Ibaraki Prefecture. Due to the effects of ground subsidence, the stacked cardboard boxes were leaning. For concentrated repairs over a short period, the Upcon method was adopted, and our company carried out the work with multiple plant vehicles. 【Case Overview】 ■ Construction Area: Approximately 2,000m2 ■ Maximum Subsidence: 110mm ■ Location: Large product storage warehouse in Ibaraki Prefecture ■ Construction Period: 6 days (Day 1: 4 vehicles, Days 2-6: 2 vehicles for construction) *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a case of "floor sinking correction" and "underfloor void filling work" carried out at a distribution station of a product manufacturer located in Niigata Prefecture. Due to consolidation settlement, various areas within the station exhibited sinking and sagging, prompting the adoption of the Upcon method, which allows for quick corrections. Since the area requiring correction was extensive, we utilized weekends during business shutdowns to divide the construction period and carry out the work. 【Case Overview】 ■ Construction Area: Approximately 1,460m2 ■ Maximum Settlement Amount: 103mm ■ Maximum Void Amount: 90mm ■ Area: Distribution station of a product manufacturer located in Niigata Prefecture ■ Construction Period: 8 working days (Note: The construction was carried out in several phases) *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a case of "outdoor concrete floor settlement correction" and "underfloor void filling work" carried out at a logistics center in Okayama Prefecture. The sloped area at the building entrance was sagging due to ground subsidence, so we adopted the Upcon method, which allows for quick correction of the sagging to avoid disrupting normal operations. After construction, we were able to almost eliminate the sagging in the center and correct it to a straight slope that feels natural. 【Case Overview】 ■ Construction Area: Approximately 410m2 ■ Maximum Settlement: 93mm ■ Maximum Void: 150mm ■ Area: Logistics center located in Okayama Prefecture ■ Construction Period: 4 days *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a case of "settlement repair work" carried out at the office and parts warehouse of an automobile manufacturer located in Hokkaido. Due to the settlement, the building was tilting, causing issues with the opening and closing of doors, and gaps had formed in the ceiling. Therefore, the company adopted the Upcon method, which allows for construction without stopping operations and can be completed in a short time. After the work was completed, the floor levels throughout the office and parts warehouse were corrected, and the gaps in the walls that had existed before the construction were also improved. 【Case Overview】 ■ Construction area: 345m2 ■ Maximum settlement amount: 63mm ■ Maximum gap amount: 70mm ■ Area: Office of an automobile manufacturer located in Hokkaido ■ Construction period: 3 days *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a case of "floor sinking correction and void filling work" carried out at a warehouse and factory located in Hokkaido. Due to the effects of ground subsidence, there were signs of sinking and sagging in the floor, and we received a request for correction from the company. Before the work, the storage racks for goods, which had tilted due to floor sinking, were adjusted in height using spacers, but after the work, they became flat. 【Case Overview】 ■ Construction Area: 334m2 ■ Maximum Subsidence: 105mm ■ Construction Period: 3 days ■ Area: Sapporo City, Hokkaido *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Here is a case study of "floor sinking correction work" carried out at a factory in Iwate Prefecture. At this factory, the floor had sunk due to ground subsidence, causing issues such as materials and cargo not stacking straight and forklifts being unable to access certain areas. The maximum subsidence was approximately 130mm, and the area of the work was about 2000m2, but the correction was completed in 16 days. 【Case Overview】 ■ Work Area: Approximately 2000m2 ■ Maximum Subsidence: Approximately 130mm ■ Maximum Gap: Approximately 80mm ■ Area: Iwate Prefecture ■ Construction Period: 16 days *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a case of "settlement correction work and unevenness correction work" carried out on the second-floor floor of a food factory located in Kanagawa Prefecture. Unevenness occurred in the floor panels of the refrigerated room, hindering the movement of carts transporting goods, and the floor panels were being held down with anchors to suppress the unevenness. After the construction, the settlement in front of the entrance was resolved, and the floor panels' floating issue was also eliminated by filling the urethane layer with new urethane. 【Case Overview】 ■ Construction Area: 46.17m² ■ Maximum Settlement Amount: 42mm ■ Void Amount: 46.17 ■ Area: Kanagawa Prefecture ■ Construction Period: 4 days (including ancillary work) *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a case of "filling voids and cavities under the concrete floor and vibration mitigation work" carried out at a precision sheet metal processing factory located in Yamagata Prefecture. This client is a repeat customer for whom we performed void and cavity filling work in 2017. This time, the request was for filling voids and cavities under the concrete floor and stabilizing the ground as a vibration mitigation measure for the installation of new machinery within the factory. Before the work, the void volume was 70mm, and after the work, there were no voids. We confirmed through CCD camera inspection that the polyurethane resin was densely filled, and the work was completed. 【Case Overview】 ■ Construction Area: 432m2 ■ Maximum Void Volume: 70mm ■ Area: Yamagata Prefecture ■ Construction Period: 3 days *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Here is an example of "floor sinking correction work" carried out at a parts assembly factory in Fukuoka Prefecture. Due to the sinking, the floor was slanted, making it difficult to adjust the jacks during conveyor assembly. As a result of the construction, we were able to improve the situation to the point where assembly work could be carried out smoothly. 【Case Overview】 ■Issue - The floor was slanted due to sinking, making jack adjustments during conveyor assembly cumbersome. ■Result - The situation was improved to the point where assembly work could be carried out smoothly. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Here is a case study of "floor slab subsidence correction work" conducted at a precision parts factory in Shizuoka Prefecture. The factory's floor slab had subsided by a maximum of 50mm, with a correction area of approximately 81m2. The construction period was one day. The injection work was carried out while checking the height with a laser level, and after the resin injection, the filling confirmation was performed using a CCD camera. 【Case Overview】 ■ Construction Area: Approximately 81m2 ■ Maximum Subsidence: 50mm ■ Area: Shizuoka Prefecture ■ Construction Period: 1 day *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a case of "void filling work and vibration suppression work" carried out at a parts factory in Aichi Prefecture. The parts factory is equipped with high-performance machining equipment. Due to the ground conditions where the factory is built, a few millimeters of void filling was implemented as a preventive measure for vibration suppression. The construction area was approximately 279m², and the construction period was two days during the daytime. The work was carried out without moving any items within the factory after taking precautions before construction. 【Case Overview】 ■ Construction Area: Approximately 279m² ■ Area: Aichi Prefecture ■ Construction Period: Two days during the daytime *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a case of "floor slab settlement correction work" and "floor slab void filling work" carried out at a precision machinery factory in Kagoshima Prefecture. There were voids and cavities of about 30 to 40 mm beneath the factory's floor slab, and due to the settlement of the floor along with the columnar improvement, a request for correction was made to Upcon. The construction was completed over two days during the factory's weekend break. After the work was finished, we received a thank-you email from the customer stating, "It was successfully lifted, and I was moved." 【Case Overview】 ■ Construction Area: Approximately 480 m2 ■ Maximum Settlement Amount: 41 mm ■ Maximum Void Amount: 35 mm ■ Area: Kagoshima Prefecture ■ Construction Period: 2 days *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a case of "floor sinking correction work and step correction work" conducted at the site of a warehouse in a factory located in Chiba Prefecture. We considered using it as a new factory. Without replacing the floor, we adopted the Upcon method, which allows for quick corrections, and carried out the construction. Before the construction, there was a step of about 80mm at the factory entrance, but it was resolved after the work. If you have any issues with the concrete floor in your factory, please feel free to contact us. 【Case Overview】 ■ Construction Area: 660m2 ■ Maximum Sinking Amount: Approximately 110mm ■ Area: Chiba Prefecture ■ Construction Period: 5 days *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Here is a case study of "floor sinking correction work" conducted at a packaging material factory in South Korea. With ground subsidence, the concrete floor also sank, causing the stacked cardboard and other materials in the factory to tilt, which hindered operations. We performed polyurethane resin injection work, continuously checking the level while correcting the subsidence. The correction was completed in 4 days using one construction plant vehicle. 【Case Overview】 ■ Construction Area: Approximately 360m2 ■ Location: Incheon, South Korea ■ Construction Period: 4 days *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a case of "filling work for floor voids, cavities, and looseness" carried out at a manufacturing factory in Gunma Prefecture. It was necessary to compact and strengthen the ground around the machinery while filling the voids, so we adopted the Upcon method, which allows work to be done in a narrow space without removing the machinery. We performed resin injection work while constantly checking the level, and after construction, we confirmed the resin filling using a CCD camera. 【Case Overview】 ■ Construction Area: Approximately 140m2 ■ Area: Gunma Prefecture ■ Construction Period: 1 day *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a case of "filling voids and cavities under the concrete floor" carried out at a waste disposal facility in Chiba Prefecture. Due to the influence of weak ground, the ground subsided, creating large voids under the concrete floor. We injected polyurethane resin under the concrete to fill the voids. After construction, it can be visually confirmed that polyurethane resin has been filled directly beneath the areas where the concrete floor was excavated. [Case Overview] - Construction Area: Approximately 710m² - Maximum Void: 180mm - Area: Chiba Prefecture - Construction Period: 4 days *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a case of "floor sinking correction work (earthquake recovery work)" carried out at a food processing factory in Iwate Prefecture. Due to the impact of the Great East Japan Earthquake, extensive renovations were necessary, and to achieve a swift recovery, the Upcon method, which allows for quick corrections, was adopted. The construction area was approximately 1,135 m², with a maximum gap of 221 mm. The construction period was six days, utilizing two construction plant vehicles. [Case Overview] - Construction Area: Approximately 1,135 m² - Maximum Gap: 221 mm - Area: Iwate Prefecture - Construction Period: 6 days (Handled by 2 construction plant vehicles) *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a case where "floor sinking correction work" and "void filling work under the floor" were carried out at a parts manufacturer factory in Fukushima Prefecture. There were various areas within the factory experiencing sinking and deflection, resulting in a wavy floor and the occurrence of voids in addition to the sinking. After the construction, the factory floor was corrected to a nearly level state, and to suppress vibrations caused by forklift passage, we focused on injecting and filling the corridor areas to mitigate the vibrations. [Case Overview] ■ Construction Area: Approximately 1,470 m² ■ Maximum Sinking Amount: 40 mm ■ Maximum Void: 60 mm ■ Area: Parts manufacturer located in Fukushima Prefecture ■ Construction Period: 11 days *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a case of "filling work for loosening under the machine foundation and urethane filling work inside the pit" conducted at a laundry factory in Kanagawa Prefecture. Due to the loosening of the ground under the machine foundation, the dewatering machine tilted, so we performed filling work to inject urethane under the machine foundation to resolve the ground loosening. Additionally, we carried out work to fill urethane inside the pit where the dewatering machine is installed to prevent further subsidence. After the construction, we conducted a filling confirmation using a CCD camera and confirmed that the urethane was evenly filled under the machine foundation. [Case Overview] ■ Construction Area: 10m² ■ Construction Period: 1 day ■ Area: Kanagawa Prefecture *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a case of "floor sinking correction work and deflection correction work" conducted at a metal processing factory in Fukuoka Prefecture. Due to ground subsidence over the years, the floor of the corridor inside the factory sagged, creating gaps between the walls and the floor. To address the floor sagging and eliminate the gaps between the walls and the floor, subsidence correction work was carried out. After the work was completed, areas that had sunk by up to 72mm, including the maximum subsidence point, were corrected to within management values, and the gaps that had formed between the walls and the floor due to subsidence were also resolved. [Case Overview] ■ Construction Area: 114m2 ■ Construction Period: 1 day ■ Maximum Subsidence: 72mm ■ Area: Fukuoka Prefecture *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a case of "filling the voids under the concrete floor in the turbine room" at a sugar factory in Hokkaido. During excavation work next to the external building of the turbine room for another project, a void with a depth of 380mm was discovered under the concrete floor. Since a turbine is installed above in the building, we implemented void filling work as a measure to prevent subsidence. We injected polyurethane resin under the concrete floor in the turbine room to fill the voids, and after the injection, we confirmed the filling using a CCD camera, ensuring that the polyurethane resin was densely filled, and completed the work. 【Case Summary】 ■ Construction Area: Approximately 70m2 ■ Maximum Void Depth: 380mm ■ Construction Period: 1 day ■ Area: Kamikawa District, Hokkaido *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Upcon specializes in the repair of concrete floors in building structures (factories, warehouses, stores, residential buildings, school facilities, etc.) and concrete pavement slabs commonly used in highways and port facilities, which have suffered from subsidence, tilting, step differences, bending, gaps, and voids caused by disasters such as earthquakes and liquefaction. Using specially developed high-strength urethane resin, we make repairs without halting operations and within a short construction period. Since its establishment in 2003, Upcon has been involved in many recovery and reconstruction projects due to significant earthquakes and other disasters. Examples and information about recovery projects are provided at the link below. We hope this will serve as a reference for those considering recovery work.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The Upcon method, which allows for modifications without breaking existing concrete pavement slabs and within a short construction period, has been widely adopted in public works such as roads and airports as a maintenance repair method. This time, we will introduce a case of subsidence correction work for the RTG (rubber-tired gantry crane) running path slab at a container terminal within a port. Over time, the RTG running path slab had subsided, causing a step to form in the adjacent vehicle running path. Additionally, unevenness occurred in the longitudinal direction, which affected the operation of the RTG and snow removal work. Compared to other methods, the Upcon method was chosen because it allows for construction without breaking the RTG running path slab and without halting operations during the short construction period. 【Site Information】 Construction Area: 258 square meters Maximum Correction Amount: 57 mm Construction Period: 6 days (nighttime) For detailed explanations and visuals of the construction, please refer to the PDF download below.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In 2021, the earthquake off the coast of Fukushima caused multiple ground fissures in the loading area and storage yard of the Hibari district in Ishinomaki and Shiogama ports. Traditionally, repairs for similar ground fissures involved open excavation down to the deepest part of the fissure, followed by repeated compaction to create a subgrade. However, this time there were several challenges, leading to the decision to explore methods that could fill the fissures without excavation and within a short construction period. Among these, the Upcon method was adopted as the most effective technique. 【Site Information】 Total construction length: 503 m Maximum depth of fissure: 2,400 mm Construction period: 5 days For detailed explanations and observations of the construction, please refer to the PDF download below.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The Upcon concrete slab settlement correction method (KT-080008-A, NETIS registration period ended in October 2014) quickly resolves issues such as settlement, unevenness, flapping, gaps, and voids that occur in concrete pavement slabs commonly used in highways and other areas, using specially developed high-strength polyurethane resin. It achieves a short construction period by utilizing a highly mobile plant without breaking the existing pavement slabs or requiring excavation work. This minimizes the period of service suspension and has a proven track record as a planned and efficient method for maintaining social infrastructure. This technology is also adopted not only for highways but also for repair work in ports and airport aprons, as well as disaster recovery work. Upcon will exhibit at the "Highway Techno Fair 2023," where cutting-edge technologies supporting highways will be showcased. Date: November 9 (Thursday) and 10 (Friday), 2023, from 10:00 to 17:00 Location: Tokyo Big Sight, West Hall 3 Exhibition Booth No: A-04 On that day, there will also be a demonstration of settlement correction using polyurethane resin. We invite you to take this opportunity to see it. We look forward to your visit.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

A step in the concrete pavement caused by sinking. It affected vehicle movement when passing through the toll booth on the highway. We injected polyurethane resin under the sunken concrete pavement slab and corrected the 30mm step in a short time. 【Site Information】 Ehime Prefecture Total construction area: Approximately 12 square meters Construction period: One night Maximum step height: 30mm Please watch the fast-motion video showing the concrete pavement slab being lifted by the foaming pressure of the polyurethane resin from below.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

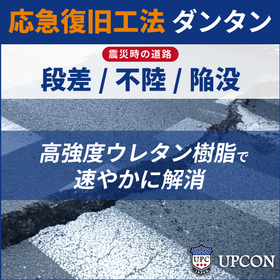

The new method "Emergency Restoration Method Dantan" developed by Upcon involves spraying high-strength polyurethane resin onto road unevenness caused by disasters during earthquakes to create a slope, enabling temporary vehicle passage for the early establishment of emergency transportation routes. A truck equipped with all necessary materials rushes to the site and sprays a two-component polyurethane resin onto the created unevenness. The high-strength polyurethane resin has the property of hardening immediately after spraying, allowing for vehicle passage within 15 minutes after the slope is created. Additionally, it can be used to repair not only unevenness but also depressions and subsidence. Features of the Emergency Restoration Method Dantan: - Ability to create slopes tailored to the shape of the disaster-affected site - Resolution of unevenness in about one hour, allowing immediate vehicle passage Furthermore, it has a proven track record in correcting tilts and unevenness of concrete floors and pavement slabs caused by earthquakes or ground subsidence, as well as filling voids. [Exhibiting at EE Tohoku '23] We will be exhibiting at the comprehensive exhibition of new technologies, EE Tohoku '23. At our booth, we will conduct demonstrations using polyurethane resin. Location: Yume Messe Miyagi Dates: June 7 (Wed) - 8 (Thu) Booth No: West Hall Exhibition B-708

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Upcon Method" is a concrete floor slab sinking correction method that quickly rectifies floor tilts, steps, and voids caused by earthquakes or ground subsidence using rigid polyurethane resin. It does not require the dismantling of existing floors, nor does it necessitate the movement of machinery or products, allowing for corrections to be made without stopping operations or business. In addition to correcting sinking and filling voids in concrete floors of factories, warehouses, stores, and slab foundation houses, the "Upcon Method" is widely adopted for correcting steps and fluttering in concrete pavement slabs of roads and port facilities. 【Features of the Upcon Method】 ■ Short construction period Reduces construction time to about 1/10 of conventional concrete replacement methods. ■ No interruption of operations or business Since there is no need to move machinery or goods, construction can be carried out without stopping production lines or business operations. ■ Comprehensive high technical capability Construction is performed by 100% in-house technical staff who have received specialized training. Floor levels are managed to the millimeter, providing a high-precision finish. ■ Compact construction system Construction can be carried out using a truck equipped with all necessary materials and equipment, eliminating the need for large plant installation or removal. *For more details, please refer to the PDF materials (catalogs and case studies) or contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The expressways that suffered tremendous damage due to the Great East Japan Earthquake. On the Tohoku Expressway, there were 347 km of damage, and on the Joban Expressway, 153 km, with collapses and uneven road surfaces occurring at four interchanges. Upcon is conducting corrections for the sinking of concrete slabs on roads and airport aprons. Full-scale restoration work began the year after the earthquake, and our technology, which allows for corrections without breaking existing slabs and within a short construction period, was adopted for the restoration work. This time, we will introduce a case of disaster recovery work for concrete pavement slabs at the Nagareyama tollgate, commissioned by East Nippon Expressway Company. Due to the sinking of the concrete pavement slabs, the water gradient could not be maintained, resulting in puddles forming in front of the ETC sensors. Every time a vehicle passed, water splashed, causing malfunctions in the sensors. We carried out sinking correction work using the Upcon method and restored the water gradient within a short construction period. 【Site Information】 Chiba Prefecture / Nagareyama IC Total construction area: 875 square meters Construction period: 8 nights

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The Kanmon Tunnel connecting Fukuoka Prefecture and Yamaguchi Prefecture. When large vehicles pass through the toll booth near the tunnel entrance and exit, vibrations were occurring in the nearby residential area. An investigation conducted by FWD revealed the presence of voids believed to be the cause of the vibrations directly beneath the concrete pavement slabs. The Upcon method is a technique that involves injecting rigid polyurethane resin beneath the concrete pavement slabs. The filling and compaction effects of the polyurethane can resolve the loosening and voids in the subgrade that cause vibrations. The Upcon method was adopted with the aim of suppressing slab vibrations by improving the environment of the upper subgrade. 【Site Information】 Fukuoka Prefecture - Yamaguchi Prefecture / Kanmon Tunnel Total construction area: Approximately 200 square meters Construction period: 2 nights

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This time, we will introduce a construction case of a logistics warehouse in Niigata Prefecture. In this logistics warehouse, ground subsidence caused unevenness and cracks in the concrete floor, which hindered the movement of carts and work operations. The Upcon method allows for construction to be carried out without stopping operations and within a short construction period. Additionally, during the injection of polyurethane resin, a surveyor is always present to manage the floor level to the millimeter, ensuring a high-quality finish. 【Site Information】 Niigata Prefecture / Logistics Warehouse Construction Area: 1,148 square meters Maximum Subsidence: 71mm Construction Period: 8 days

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

■There is a sense of discomfort when entering the classroom. ■The floor is slanted, posing a risk of injury or worsening health. ■The slanted floor causes the desks to wobble. ■Windows and doors are difficult to close. ■The gym floor is warped. ■The gym stage is distorted. ■Puddles form by the poolside. The "Upcon Method," which uses polyurethane resin, quickly resolves issues caused by floor slanting and warping due to earthquakes or ground subsidence, as well as voids and gaps that have formed beneath the floor.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This time, we would like to introduce a case study of a precision parts manufacturing factory in Saitama Prefecture. Due to ground subsidence, cracks and deflections occurred in the floor slab, causing vibrations in the machinery. To prevent the impact of these vibrations on product accuracy, we carried out subsidence correction work to alleviate the deflection and filling work for the voids under the floor slab. The Upcon method was adopted because it allows for construction without moving the machinery and without stopping operations. 【Site Information】 Saitama Prefecture / Precision Parts Manufacturing Factory Construction Area: 287 square meters Maximum Subsidence: 44mm Maximum Void Volume: 50mm Construction Period: 3 days You can view detailed construction information in the PDF download below.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This time, we will introduce a case study of a bag manufacturing factory in Miyagi Prefecture. Due to the impact of the Great East Japan Earthquake that occurred in March 2011, the floor sank, causing the machines to tilt and hindering production. The Upcon method was adopted because it allows for corrections to be made in a short time without moving the machines. "We cannot secure the level of the machines and are using spacers." "Malfunctions are occurring in the machines, affecting product accuracy." We receive many inquiries about floor repairs like these at Upcon. The characteristic of the Upcon method is that it can correct floor subsidence in a short time, but a significant advantage is that it does not require the movement of machines or materials for the construction. [Site Information] Miyagi Prefecture, Bag Manufacturing Factory Construction Area: Approximately 730 square meters Maximum Subsidence: 111mm Construction Period: 3 days For detailed information about the construction process, you can view it by downloading the PDF below.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The Upcon method, which allows for modifications without breaking existing concrete pavement slabs and within a short construction period, has been widely adopted in public works such as roads and airports as a maintenance and repair method. This time, we will introduce a construction site for correcting the sinking of concrete pavement slabs and filling voids at a quay in a port. The quay at Soma Port in Fukushima Prefecture, where cargo loading and unloading occurs frequently, has experienced issues due to ground subsidence, resulting in steps and sinking in the concrete pavement slabs, eliminating the water slope and causing puddles. This has hindered cargo operations. The Upcon method was chosen because it has no environmental impact compared to other methods and can correct the existing slabs without removal in a short period. [Site Information] Soma Port Port Maintenance Management Work (Quay Restoration) Construction Area: Approximately 285 square meters Maximum Subsidence: 97mm Construction Period: 4 days For detailed information on the construction process, please refer to the PDF download below.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is a construction case study of the unloading quay at Onagawa Fishing Port and Fish Market in Miyagi Prefecture. The structure allowed for the continuous surface drainage of used water and seawater from the unloading area towards the quay. However, due to ground subsidence, a step was created in the concrete pavement, causing surface drainage to form puddles, which hindered the loading and unloading of cargo and the movement of forklifts. The Upcon method was adopted because it allowed for the correction of the step without breaking the concrete pavement and within a short construction period. 【Site Information】 Disaster Recovery Work at Miyagasaki Quay, Onagawa Fishing Port Construction Area: 338 square meters Maximum Subsidence: 32mm Construction Period: 5 days For more details on the construction process, you can view the PDF download below.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration