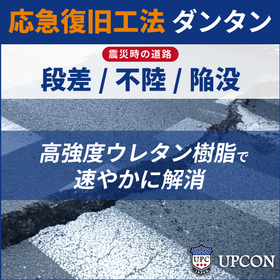

Emergency restoration method "Dantan": A new technique by the sinking correction expert Upcon.

Quickly restore road unevenness and depressions during an earthquake with polyurethane resin, enabling swift vehicle passage. Contributing to the establishment of emergency transportation routes!

The new method "Emergency Restoration Method Dantan" developed by Upcon involves spraying high-strength polyurethane resin onto road unevenness caused by disasters during earthquakes to create a slope, enabling temporary vehicle passage for the early establishment of emergency transportation routes. A truck equipped with all necessary materials rushes to the site and sprays a two-component polyurethane resin onto the created unevenness. The high-strength polyurethane resin has the property of hardening immediately after spraying, allowing for vehicle passage within 15 minutes after the slope is created. Additionally, it can be used to repair not only unevenness but also depressions and subsidence. Features of the Emergency Restoration Method Dantan: - Ability to create slopes tailored to the shape of the disaster-affected site - Resolution of unevenness in about one hour, allowing immediate vehicle passage Furthermore, it has a proven track record in correcting tilts and unevenness of concrete floors and pavement slabs caused by earthquakes or ground subsidence, as well as filling voids. [Exhibiting at EE Tohoku '23] We will be exhibiting at the comprehensive exhibition of new technologies, EE Tohoku '23. At our booth, we will conduct demonstrations using polyurethane resin. Location: Yume Messe Miyagi Dates: June 7 (Wed) - 8 (Thu) Booth No: West Hall Exhibition B-708

Inquire About This Product

basic information

Upcon's main business is to correct the sinking, tilting, steps, and gaps in concrete floors caused by uneven ground subsidence in buildings such as factories, warehouses, stores, and general residences using our unique "Upcon Method," which employs completely non-fluorinated urethane resin and small machinery. Additionally, to promote new business development, we are advancing numerous projects and engaging in research and development for new application fields of rigid foam urethane resin, aiming to create a cycle of developing our business while creating our own market as a research and development-oriented company. ■ What is the Upcon Method? For existing concrete floors and concrete pavement slabs that have experienced sinking, steps, tilting, voids, or gaps, we drill small holes with a diameter of 16mm and inject urethane resin while continuously monitoring the floor level in millimeter increments. The resin injected beneath the floor or slab expands under pressure in a short time, compacting and strengthening the ground, improving the bearing capacity, and pushing up the concrete floor or pavement slab from below to correct it. Even if voids or cavities occur beneath the floor or slab, we fill the gaps with urethane resin using the same method.

Price range

Delivery Time

Applications/Examples of results

Repair work for sunken earthen floors / Filling work for gaps under earthen floors Repair work for sunken concrete pavement slabs / Filling work for gaps under concrete pavement slabs Emergency restoration work for roads after an earthquake

catalog(18)

Download All Catalogs![[Construction Case Studies / Residential Edition Vol. 1] Foundation Settlement Correction Work for Slab Foundation Houses](https://image.www.ipros.com/public/catalog/image/01/932/646288/IPROS8420661192824606858.jpg?w=120&h=170)

![[Construction Case Study/Port Edition Vol. 1] Port Maintenance Management Work (Quay Restoration) Subsidence Correction and Void Filling](https://image.www.ipros.com/public/catalog/image/01/93a/646469/IPROS7250851689726681210.jpeg?w=120&h=170)

![[Construction Case Study / Port Edition Vol. 2] Onagawa Fishing Port Miyagazaki Quay Disaster Recovery Project](https://image.www.ipros.com/public/catalog/image/01/f20/647656/IPROS5098479422774090087.jpg?w=120&h=170)

![[Construction Case Study/Warehouse Edition Vol. 3] Correction of Floor Settlement (Leveling Correction) in a Logistics Center](https://image.www.ipros.com/public/catalog/image/01/440/691142/IPROS92327252784948285479.jpeg?w=120&h=170)

![[Construction Case Study/Road Edition Vol. 2] Joban Expressway Nagareyama IC Restoration and Repair Work](https://image.www.ipros.com/public/catalog/image/01/d1a/652747/IPROS13288921954826130650.jpg?w=120&h=170)

![[Construction Case Study/Road Edition Vol. 1] Kanmon Tunnel Concrete Pavement Slab Void Filling Work](https://image.www.ipros.com/public/catalog/image/01/67d/652383/IPROS18287232451842893111.jpg?w=120&h=170)

![[Construction Case Study/Factory Edition Vol. 1] Settlement Correction and Void Filling Work for a Bag Manufacturing Factory](https://image.www.ipros.com/public/catalog/image/01/2e3/649428/IPROS09434185074319628739.jpeg?w=120&h=170)

![[Construction Case Study/Factory Edition Vol.2] Settlement Correction and Void Filling Work for Precision Parts Manufacturing Factory](https://image.www.ipros.com/public/catalog/image/01/60a/649429/IPROS31170878921170722761.jpeg?w=120&h=170)

![[Construction Case Study Factory Edition Vol. 3] Correction Work for Sunken Floor Slab in a Metal Processing Factory](https://image.www.ipros.com/public/catalog/image/01/7cc/727508/IPROS94865378217145340721.jpeg?w=120&h=170)

![[Construction Case Study/Warehouse Vol.2] Settlement Correction Work for Automobile Manufacturer's Office and Parts Storage](https://image.www.ipros.com/public/catalog/image/01/d82/644772/IPROS41981554215493828964.png?w=120&h=170)

![[Construction Case Study/Warehouse Vol. 1] Settlement Correction and Void Filling Work for Warehouse and Factory](https://image.www.ipros.com/public/catalog/image/01/d17/644938/IPROS68258418151929232212.jpeg?w=120&h=170)

![[Construction Case Study / Port Edition Vol. 4] Sendai Shiogama Port (Ishinomaki Area) Hibari-no Chuo Pier Quay Disaster Recovery Work](https://image.www.ipros.com/public/catalog/image/01/6e4/734399/IPROS3107554405782613509.jpeg?w=120&h=170)

Company information

We carry out construction to correct the sinking, tilting, steps, and gaps in concrete floors caused by uneven ground subsidence in buildings such as factories, warehouses, stores, and general residences, using our unique "Upcon Method" with completely non-fluorinated urethane resin and small machinery. Additionally, we are engaged in public works that utilize technologies developed through various research and development projects to restore the functionality of aging social infrastructure such as roads, airports, ports, and agricultural waterways. ■ Features of the Upcon Method 1. Short construction period: The construction time is 1/10 of conventional methods. 2. No interruption of operations: No need to move machinery or cargo. 3. Comprehensive high technical capability: 100% in-house employees. 4. Compact construction system: Quick restoration to the current state is possible. 5. Reduced risk of re-subsidence: Lower risk of re-subsidence compared to conventional methods. Our in-house staff provides total support from on-site surveys across the country to repair planning and construction, taking full responsibility. Our specialized and experienced in-house staff will propose the optimal repair plan tailored to your site. Upcon Co., Ltd. was newly listed on the Nagoya Stock Exchange Next Market on December 26, 2022.

![[Road Section] Concrete Pavement Slab Repair Method](https://image.www.ipros.com/public/catalog/image/01/517/569862/IPROS83319363143977941547.jpeg?w=120&h=170)

![[Factory/Warehouse Edition] Concrete Floor Slab Settlement Correction Method](https://image.www.ipros.com/public/catalog/image/01/a8b/574717/IPROS26834563507502257761.jpeg?w=120&h=170)

![[Construction Case Studies/Road Edition Vol. 3] Kumamoto Area Maintenance Work](https://image.www.ipros.com/public/catalog/image/01/e51/734403/IPROS53906301993472782704.png?w=120&h=170)

![[NETIS Registration] A new method for quickly repairing deteriorated gutters due to aging.](https://image.www.ipros.com/public/product/image/ea9/2000307859/IPROS508159914279188733.jpg?w=280&h=280)