1~45 item / All 51 items

Displayed results

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us OnlineBefore making an inquiry

Download PDF1~45 item / All 51 items

Have you ever faced any of these issues when performing construction using thrusting methods? ▶ Construction was halted due to encountering obstacles like wooden stakes or H-beams... ▶ The time and cost of construction increased, leading to delays or interruptions... ▶ Construction over difficult distances could not be managed with standard equipment and methods... The "Milling Mole Method" solves these problems associated with thrusting methods! 【Example of a resolved case】 ✔ Sewer construction in Osaka City Planned to push 127 meters in one span using a standard mud slurry method with a diameter of φ80mm. Immediately after starting, the machine encountered wooden stakes, making it impossible to proceed, and the excavation was halted. By changing the plan to adopt the Milling Mole Method, the presence of obstacles was confirmed by discharging wood chips, and the thrusting was completed. ✔ Sewer construction in Osaka Prefecture Planned to push 119 meters in one span using a standard mud slurry method with a diameter of φ1800mm. While excavating about 10 meters, the machine encountered support piles of a bridge pier, making it impossible to proceed, and both the excavation machine and thrusting pipe were left underground. By changing the plan to adopt the Milling Mole Method, re-excavation was carried out from the same launch shaft. The reinforced concrete pipe that became an obstacle was cut, and the discharge of metal fragments, thrusting pipe collars, and rebar was confirmed, allowing safe passage through the obstacle section, and the thrusting was completed. *We are currently providing materials such as "Case Studies of Problem Solving" and "Comparison of Methods for Dealing with Obstacles in Thrusting Methods" from the PDF!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

You can download the materials comparing the methods for dealing with obstacles in the push construction method from CASE 1 to CASE 4, along with a comprehensive evaluation and overall judgment based on aspects such as estimated construction period, estimated construction costs, safety, and reliability of construction. 【Model Case】 Pipe Diameter: 1000mm Push Length: 100m Cover Depth: 10m Target Obstacle: H-200×1 location Soil Type: Ordinary 【Comparison of Obstacles in Push Construction Method】 ▶Normal Push The normal push method is used, but when encountering an obstacle, the tunneling machine is left in place, and the height of the pipeline is changed for re-pushing. ▶Normal Push The normal push method is used, but when encountering an obstacle, a shaft for obstacle removal is constructed, and the obstacle is manually removed before re-pushing. ▶Normal Push The normal push method is used, but when encountering an obstacle, the tunneling machine is left in place. ▶Milling Mole The route of the pipeline is changed for re-pushing, and the obstacle is directly cut using a milling mole tunneling machine.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Yasuda Engineering Co., Ltd. will conduct a seminar at the 44th "Latest Construction Technology Seminar on Advanced Propulsion Methods" held in Tokyo and Osaka. We will report on our new initiatives utilizing the steel obstacle cutting function of the milling mole method. This seminar is accredited as a "Continuing Professional Development (CPD) Program" by the Japan Society of Civil Engineers. (CPD credits: 6.5) We sincerely look forward to your attendance. [Overview] ■ Seminar Time: 14:55 - 15:50 ■ Seminar Content: Challenging New Areas with the Milling Mole Method - New Initiatives Utilizing the Steel Obstacle Cutting Function - *For application details, please refer to [Details on How to Apply for Participation Here]. *For more information, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Milling Mole Method" is equipped with a specialized bit designed for cutting through obstacles using a tunneling machine. It allows the cutter of the tunneling machine to make ultra-low-speed contact with obstacles through a special telescopic pipe, enabling cutting through the rotation of the cutter. This operates on the same principle as lathe machining. A significant feature of this construction using the "Milling Mole Method" is that it achieved direct cutting of steel segments without performing mirror cutting. Since improvements to the protective measures of the existing shield section could not be made from the surface, a boring machine was mounted, allowing for injection from within the tunneling machine (using a dual-pipe strainer method with multiple phases). Additionally, a formwork for cutting connection was installed inside the existing shield, and fluidized treatment soil was placed, allowing for direct cutting at ultra-low speeds and safely avoiding the risks of water inflow and subsidence accidents that occur during mirror cutting. Previously, mirror cutting was performed from within the shield, raising concerns from customers about the risks to the surrounding environment due to groundwater inflow and ground collapse associated with that construction. We proposed direct cutting of the existing shield, and after executing the construction, we successfully reached the target without affecting water inflow or the surrounding environment, resulting in great satisfaction from the client! 《You can download the construction case from the PDF below!》

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

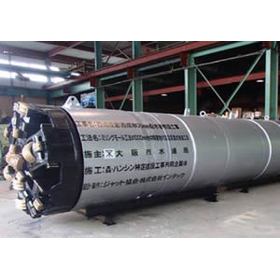

The "Milling Mole Method," a ground obstacle response type mud-based thrusting method equipped with four special functions: exploration, improvement, cutting, and guidance, consists of three devices: a tunneling machine, a special telescopic pipe, and a special injection pipe, allowing for the fine cutting and discharge of underground obstacles. This document includes case studies of electrical work using the Milling Mole Method. It features photos of underground obstacles cut on-site, along with comments from the site personnel. [Featured Cases] ■ New pipeline construction related to Oi Thermal Power Substation in Shinagawa, Tokyo ■ New pipeline construction for the 110kV Mitsubishi Enaba Line in Hiroshima City, Hiroshima Prefecture ■ Civil engineering work related to biomass interconnection in Hachinohe City, Aomori Prefecture *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Milling Mole Method," equipped with four special functions: exploration, improvement, cutting, and guidance, is a ground obstacle response type mud-based thrusting method. It consists of three devices: a tunneling machine, a special telescopic pipe, and a special injection pipe, allowing for the precise cutting and removal of underground obstacles. In the construction of the inflow pipe sewer system for the second Nakagawa Chubu rainwater adjustment pond, the Milling Mole Method was used to carry out the shield arrival work. Milling cutting length: The assembly precision of the steel formwork at the arrival section inside the existing shield, L=1.520m from the outer circumference of the existing shield, was excellent, and there were no leaks of groundwater or muddy water during the placement of fluidized treated soil or during the shield cutting with the tunneling machine, allowing for safe cutting. 【Construction Example】 ■Location: Nagoya City, Aichi Prefecture ■Client: Nagoya City Waterworks Bureau ■Contractor: Asanuma Corporation ■Nominal Diameter: φ2200mm ■Thrusting Length: 101.520m ■Underground Obstacles: Direct access to the existing shield Inner diameter of the existing shield φ3750mm *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The underground obstacle response type mud-based thrusting method "Milling Mole Method," equipped with four special functions: exploration, improvement, cutting, and guidance, consists of three devices: a tunneling machine, a special telescopic pipe, and a special injection pipe, allowing for the precise cutting and removal of underground obstacles. This document includes case studies of gas construction using the Milling Mole Method. It features photos of underground obstacles cut on-site, along with comments from the site personnel. [Featured Cases] ■ New tunnel construction for the 2-1 Otemachi District plan in Chiyoda Ward, Tokyo ■ Installation of the Ise Bay crossing gas pipeline in Yokkaichi City, Mie Prefecture (gas conduit construction) ■ Main construction for the MAKP750A in North Shinagawa, Shinagawa Ward, Tokyo (Sankyo Bridge Phase III construction) *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This document is a collection of case studies on water supply construction by Yasuda Engineering Co., Ltd. The underground obstacle-responsive mud-based thrusting method "Milling Mole Method," equipped with four special functions: "exploration, improvement, cutting, and guidance," consists of three devices: a tunneling machine, a special expandable pipe, and a special injection pipe, allowing for the precise cutting and removal of underground obstacles. We have completed requests from customers using this method. [Featured Cases] ■ Installation of water supply main around Hanjin-cho, Sasebo City, Nagasaki Prefecture (No. 6) ■ New installation of water supply main (500mm) and replacement of water supply main (600mm) from Nishidai 2-chome to Nishidai 1-chome in Itabashi Ward, Tokyo ■ Improvement work on the Shinjo trunk line (Higashiyodogawa 3) 700mm water supply pipe (installation of 1000mm water supply pipe) and others *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This document is a collection of case studies on sewer construction by Yasuda Engineering Co., Ltd. The "Milling Mole Method," a trenchless construction method equipped with four special functions: "exploration, improvement, cutting, and guidance," consists of three devices: a tunneling machine, a special telescopic pipe, and a special injection pipe, allowing for the precise cutting and removal of underground obstacles. We have completed requests from our clients using this method. [Featured Cases] ■ Sewer pipe installation work in Chuo Ward, Tokyo (28 Seigo-2) ■ Sewer construction work near 3-chome, Tomikawa-cho, Nakagawa Ward, Nagoya City, Aichi Prefecture ■ Sewer construction work in the 7th section of the Onchigawa East drainage area, Yao City, Osaka Prefecture, fiscal year 2015 *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

You can explore and cut through obstacles buried underground by connecting to existing shields! Since it can be connected with fewer processes, it leads to a reduction in construction time and cost. The 'Milling Mole Method,' equipped with four special functions: "exploration, improvement, cutting, and guidance," consists of three devices: a tunneling machine, special bits, and special telescopic pipes, allowing for the precise cutting and removal of underground obstacles. Using electromagnetic waves, it explores metal obstacles ahead while advancing the tunneling process, and it is also possible to improve the ground from inside the tunneling machine before and after the detected obstacles. If an obstacle is detected, a special telescopic device can be used to cut through the underground obstacle at ultra-low speed, allowing the advancement to continue. The system also includes a mechanism to install a receiving coil at a designated position within the access shaft, guiding the tunneling machine to that position, ensuring high precision in reaching the target even when obstacles are encountered.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Due to the progress of global warming, abnormal weather such as guerrilla rainstorms is occurring more frequently. We want to carry out sewer construction and advance rainwater measures, but we often hear that construction is not progressing due to a lack of personnel caused by Olympic construction and other projects. Even when construction begins, there are often obstacles buried underground that prevent progress, leading to wasted time and money. Therefore, we recommend the milling mole method, which is safe even when underground obstacles are encountered! The "milling mole method," equipped with four special functions: "exploration, improvement, cutting, and guidance," consists of three devices: a tunneling machine, special bits, and a special telescopic pipe, allowing for the precise cutting and removal of underground obstacles. Using electromagnetic waves, it explores and pushes forward while tunneling through metal obstacles ahead, and it is also possible to improve the ground from within the tunneling machine before and after the detected obstacles. If an obstacle is detected, a special telescopic device can be used to cut through the underground obstacle at ultra-low speed, allowing for continued advancement. The system also includes the installation of a receiving coil at a designated position within the access shaft to guide the tunneling machine to that location, making it a high-precision advancement method even when obstacles are present.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The demand for sewer construction is increasing due to the hosting of the Olympics in 2020 and sudden heavy rain, as well as measures for rainwater management. When the demand for construction rises and there is pressure to respond quickly, encountering obstacles buried underground can lead to a loss of time. Therefore, we recommend the milling mole method, which is safe even when encountering underground obstacles! The underground obstacle response type mud-based thrusting method, "milling mole method," is equipped with four special functions: "exploration, improvement, cutting, and guidance." It consists of three devices: a tunneling machine, special bits, and a special telescopic pipe, allowing for the precise cutting and removal of underground obstacles. Using electromagnetic waves, it explores and pushes forward while tunneling through metal obstacles, and it is also possible to improve the ground from within the tunneling machine before and after the detected obstacles. If an obstacle is detected, a special telescopic device can be used to cut through the underground obstacle at ultra-low speed, allowing for continued thrusting. Furthermore, a receiving coil is installed at a designated position within the access shaft, and a system is also equipped to guide the tunneling machine to that position, making it a thrusting method that can accurately reach the destination even when obstacles are present.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The demand for sewer construction is increasing due to the hosting of the Olympics in 2020 and guerrilla rainstorms, as well as measures for rainwater management. When the demand for construction rises and there is pressure to respond quickly, encountering obstacles buried underground can lead to a loss of time. Therefore, we recommend the milling mole method, which is safe even when encountering underground obstacles! The underground obstacle response type mud-based thrusting method "milling mole method," equipped with four special functions: "exploration, improvement, cutting, and guidance," consists of three devices: a tunneling machine, special bits, and special telescopic pipes, allowing for the fine cutting and removal of underground obstacles. Using electromagnetic waves, it explores and pushes forward while tunneling through metal obstacles, and it is also possible to improve the ground from inside the tunneling machine before and after the detected obstacles. In the event that an obstacle is detected, a special telescopic device can be used to cut through the underground obstacle at ultra-low speed, allowing for continued thrusting. Furthermore, a system is also equipped to install a receiving coil at a designated position inside the arrival shaft, guiding the tunneling machine to that position with high precision, even when obstacles are present.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Yasuda Engineering has numerous construction achievements in Vietnam, Indonesia, and South Korea. Unexpected underground obstacles can be encountered not only domestically but also overseas. There may be abandoned piles, sheet piles, H-beams, and other structures left underground. Our developed underground obstacle response type mud-based thrusting method, the "Milling Mole Method," can detect various obstacles left underground using electromagnetic waves. Furthermore, the discovered obstacles can be cut through with a special device. Additionally, the Milling Mole Method was awarded the "No-Dig Award 2012" by the ISTT (International Society for Trenchless Technology). 【Examples of Construction Achievements】 ■CASE-1 Cutting of Hume pipes ■CASE-2 Cutting of PC beams ■CASE-3 Cutting of H-beams and reinforced concrete ■CASE-4 Cutting of existing manhole walls made of H-beams ■CASE-5 Cutting of wire tetra pods *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

**Exhibition Overview** Exhibition Name: Sewer Exhibition '18 Kitakyushu Date: July 24 (Tuesday) - 27 (Friday), 2018, for 4 days Time: 10:00 AM - 5:00 PM Location: West Japan General Exhibition Center Booth: C-822 **Exhibited Products** ■ Subsurface Obstacle-Compatible Slurry Shield Method The milling mole method is used in urban development and is a slurry shield method that safely performs construction by cutting through obstacles left underground. It can detect obstacles ahead of the excavation and discharge them as cutting powder of about 1 cm in size. If necessary, it allows for the injection of chemicals from within the machine and guidance of the tunneling machine using GPS. ■ Jet Method The jet method uses a CCD camera sensor to instantly measure the position of the tunneling machine on sharp curves. It enables long-distance and sharp curve construction in small-diameter tunneling. By using a dedicated pump cylinder and lubricant injection pipe for the jet method, it reduces the load on the pipe, allowing for long-distance tunneling even with small diameters. It is the most excellent all-around tunneling method that does not limit construction locations due to in-pipe measurement.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Milling Mole Method," a ground obstacle response type mud-based thrusting method equipped with four special functions: exploration, improvement, cutting, and guidance, consists of three devices: a tunneling machine, a special telescopic pipe, and a special injection pipe, allowing for the precise cutting and removal of underground obstacles. Using electromagnetic waves, it explores metal obstacles ahead while thrusting and can also improve the ground from within the tunneling machine before and after the detected obstacles. In the event an obstacle is detected, the special telescopic device can be used to cut through the underground obstacle at ultra-low speed, allowing for continued thrusting. Additionally, a system is equipped to guide the tunneling machine to a designated position within the arrival shaft by installing a receiving coil at that location, making it the ultimate thrusting method capable of achieving high precision even when obstacles are encountered. 【Performance by Obstacle Type】 ■CASE-6 Steel Sheet Pile 3W Cutting ■CASE-7 Steel Sheet Pile 3 & H Steel Cutting ■CASE-8 Wooden Pile & Steel Sheet Pile Cutting ■CASE-9 H Steel & Existing Manhole Wall Cutting ■CASE-10 Underground Continuous Wall & Metal Object Cutting *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The JET method is a type of thrust construction method that excavates pipelines for sewage, water supply, gas, and electricity using a small shield machine. It is a groundbreaking technique that allows for small diameter, long-distance, sharp curves, and deep excavation. With this JET method technology, the amount of excavation from the ground is minimized, resulting in reduced noise and dust associated with construction, as well as minimal road occupation. Since the measurements are taken from the underground using CCD camera sensors from the launch shaft, they are not affected by buried objects, electric wires, or tracks. Measurements can be taken without being influenced by external factors such as under rivers, beneath railway tracks, under busy roads, and deep soil cover. 【Features】 - Supports deep thrust excavation - Simple structure and easy handling - Three-dimensional traverse surveying using high-resolution CCD camera sensors - Roll conveyor rail (patented) - Capable of handling a wide range of soil types For more details, please refer to the catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The excavation machine used in shield construction can dig horizontally through the ground and is mainly utilized for tunneling in subways and sewage systems. However, if there are underground obstacles during excavation, the construction may come to a halt. To address this, the milling mole method is enhanced by equipping the shield machine with four special functions: "exploration, improvement, cutting, and guidance," allowing it to cut through obstacles and enable long-distance advancement! The underground obstacle-responsive mud pressure propulsion method, known as the "milling mole method," consists of three devices: the excavation machine, a special telescopic pipe, and a special injection pipe, which can finely cut and discharge underground obstacles! Using electromagnetic waves, it explores and detects metal obstacles ahead while advancing, and it is also possible to improve the ground from within the excavation machine before and after the detected obstacles. If an obstacle is detected, a special telescopic device can be used to cut through the underground obstacle at ultra-low speed, allowing the propulsion to continue. 【Applicable Obstacles】 ■ Wooden piles ■ PC piles ■ Steel pipe piles ■ Steel sheet piles ■ H-beams ■ Continuous walls ■ Concrete structures

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The underground obstacle response type mud-based thrusting method "Milling Mole Method," equipped with four special functions: exploration, improvement, cutting, and guidance, consists of three devices: a tunneling machine, a special telescopic pipe, and a special injection pipe, allowing for the fine cutting and discharge of underground obstacles. Using electromagnetic waves, it explores metal obstacles ahead while thrusting and can also improve the ground from within the tunneling machine before and after the detected obstacles. In the event that an obstacle is detected, the special telescopic device can be used to cut through the underground obstacle at ultra-low speed, allowing for continued thrusting. Furthermore, a system is also equipped to guide the tunneling machine to a designated position by installing a receiving coil at the specified location within the arrival shaft, enabling high-precision arrival even in the presence of obstacles. 【Performance by Obstacle Type】 ■CASE-6 Steel Sheet Pile 3W Cutting ■CASE-7 Steel Sheet Pile 3 & H Steel Cutting ■CASE-8 Wooden Pile & Steel Sheet Pile Cutting ■CASE-9 H Steel & Existing Manhole Wall Cutting ■CASE-10 Underground Continuous Wall & Metal Object Cutting *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Milling Mole Method," a ground obstacle response type mud-based propulsion method equipped with four special functions: exploration, improvement, cutting, and guidance, consists of three devices: a tunneling machine, a special telescopic pipe, and a special injection pipe, allowing for the fine cutting and discharge of underground obstacles. Using electromagnetic waves, it explores metal obstacles ahead while propelling and can also improve the ground from within the tunneling machine before and after the detected obstacles. In the event that an obstacle is detected, a special telescopic device can be used to cut through the underground obstacle at ultra-low speed, allowing for continued propulsion. Additionally, a system is equipped to guide the tunneling machine to a designated position within the arrival shaft by installing a receiving coil at that location, making it the ultimate propulsion method that can lead to high precision even when obstacles are encountered. 【Performance by Obstacle Type】 ■CASE-6: Cutting of steel sheet piles 3W ■CASE-7: Cutting of steel sheet piles 3 and H steel ■CASE-8: Cutting of wooden piles and steel sheet piles ■CASE-9: Cutting of H steel and existing manhole walls ■CASE-10: Cutting of underground continuous walls and metal objects *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The underground obstacle response type mud-based thrusting method "Milling Mole Method," equipped with four special functions: exploration, improvement, cutting, and guidance, consists of three devices: a tunneling machine, a special telescopic pipe, and a special injection pipe, allowing for the precise cutting and discharge of underground obstacles. Using electromagnetic waves, it explores metal obstacles ahead while thrusting and can also improve the ground from within the tunneling machine before and after the detected obstacles. In the event that an obstacle is detected, the special telescopic device can be used to cut through the underground obstacle at ultra-low speed, allowing for continued thrusting. Furthermore, a system is installed to guide the tunneling machine to a designated position within the arrival shaft by placing a receiving coil at that location, making it the ultimate thrusting method that can accurately lead to the destination even in the presence of obstacles. 【Performance by Obstacle Type】 ■CASE-1 Cutting of Fume Pipes ■CASE-2 Cutting of PC Piles ■CASE-3 Cutting of H Steel and Reinforced Concrete ■CASE-4 Cutting of H Steel Existing Manhole Walls ■CASE-5 Cutting of Wire Tetrapods *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The underground obstacle-responsive mud-based propulsion method "Milling Mall Method" consists of three devices: a tunneling machine, a special expandable pipe, and a special injection pipe, which crush and discharge metallic obstacles. In the sewer construction of Section 42 in Yao City, Osaka Prefecture, the cutting and removal of a concrete pipe was carried out. Immediately after starting, the existing propulsion concrete pipe with a diameter of 1800 mm was cut diagonally over a section of 8.21 meters, which was an obstacle, and then normal tunneling was performed to reach the existing special manhole. At the existing manhole, the head was completely destroyed, and the plan was to disassemble and recover everything else. *For more details, please refer to the PDF document or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The underground obstacle-responsive mud-based thrusting method "Milling Mall Method" consists of three devices: a tunneling machine, a special expandable pipe, and a special injection pipe, which pulverizes and discharges metal obstacles. It explores metal obstacles ahead of the thrusting excavation while pushing them forward, and it is also possible to improve the ground from inside the tunneling machine before and after the obstacles. Furthermore, a receiving coil is installed at a designated position inside the arrival shaft, and a system is equipped to guide the tunneling machine to that position, making it the ultimate thrusting method that provides peace of mind even when obstacles are encountered. 【Performance by Obstacle Type】 ■CASE-1 Cutting of Hume pipes ■CASE-2 Cutting of PC beams ■CASE-3 Cutting of H steel and reinforced concrete ■CASE-4 Cutting of H steel existing manhole walls ■CASE-5 Cutting of wire tetra pods *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

One of the concerns in construction work is underground.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This document introduces the construction achievements related to the new pipeline installation work at the Oi Thermal Power Plant. This project involved the installation of new pipelines within the Oi Thermal Power Plant, and due to the site being filled, it was uncertain whether sheet piles or H-beams would be encountered; it was possible to find concrete debris or metal fragments, among other things. In reality, only pine piles and what appeared to be concrete debris from some base were encountered, and the use of expansion jacks was not necessary. 【Construction Case】 ■ Project Name: New Pipeline Installation Work Related to Oi Thermal Power Plant ■ Client: Tokyo Electric Power Company Holdings, Inc. ■ Contractor: Wakachiku Construction Co., Ltd. Tokyo Branch ■ Pipe Diameter: 1350 mm ■ Pushing Length: 190.5 m ■ Soil Type: Clayey Soil ■ N Value / Gravel Ratio / Maximum Gravel Diameter: N=2–10 G=0% φmax=100 mm ■ Construction Period: August 2015 to October 2015 (2.5 months) ■ Type of Obstacles: Insurance Method, Pine Piles, Concrete Debris, Wood Pieces *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce the construction results of the sewer pipe installation project in Umiyama Town, commissioned by the Sakai City Waterworks Bureau. It was believed that there was one location with a Type III steel sheet pile in the thrust pipeline section. The road where the thrust pipe was to be laid is a major thoroughfare with heavy traffic, making it difficult to regulate the road, so the project involved cutting the existing Type III steel sheet pile. As a result of the construction, one Type III steel sheet pile was cut. 【Construction Details】 ■ Project Name: Umiyama Town Sewer Pipe Installation Project ■ Client: Sakai City Waterworks Bureau, Sewer Division, Sewer Construction Section ■ Contractor: Union Tech Co., Ltd. ■ Pipe Diameter: 1100 ■ Thrust Length: 69.840m ■ Soil Type: Sandy Soil ■ N Value/Gravel Ratio/Maximum Gravel Diameter: N=4-9 G=0% φmax=57mm ■ Construction Period: August 2015 to September 2015 (1 month) ■ Type of Obstacle: Type III Steel Sheet Pile, 1 location *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is an introduction to the construction achievements of the reconstruction project near Nagatacho 1-chome and Kasumigaseki 2-chome, Chiyoda Ward, Phase 2. Initially, there was a possibility of two locations with reinforced concrete in the thrust pipeline section, and the thrust construction was conducted on a heavily trafficked main road. As a result of the construction, after cutting the reinforced concrete at two locations, we encountered unexpected obstacles. The unexpected obstacles were H-beams measuring H250 to H350, and we subsequently cut through six unexpected H-beams. 【Construction Case】 ■ Project Name: Reconstruction Project near Nagatacho 1-chome and Kasumigaseki 2-chome, Chiyoda Ward, Phase 2 ■ Client: Tokyo Metropolitan Sewerage Bureau ■ Contractor: Muramoto Construction Co., Ltd. Tokyo Branch ■ Pipe Diameter: 1500 ■ Thrust Length: 94.700 m ■ Soil Type: Clay ■ N Value/Gravel Ratio/Maximum Gravel Diameter: N=1-2 G=0% φmax=0mm ■ Construction Period: April 2015 to August 2015 (3.5 months) ■ Type of Obstacles: Reinforced concrete 2m thick at 2 locations Unexpected obstacles H-beams H-250 to H-350 at 6 locations *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is an introduction to the construction results of the replacement work for the water supply main (800mm and 500mm) between the vicinity of 1-chome, Nihonbashi Horitakemachi, Chuo Ward, and the vicinity of Nihonbashi Hisamatsu-cho, Chuo Ward. Initially, there was a possibility of wooden piles with a diameter of 300mm existing in the push pipe section; however, as a result of the construction, there were no wooden piles with a diameter of 300mm. 【Construction Case】 ■ Project Name: Replacement work for the water supply main (800mm and 500mm) between the vicinity of 1-chome, Nihonbashi Horitakemachi, and the vicinity of Nihonbashi Hisamatsu-cho, Chuo Ward ■ Client: Tokyo Metropolitan Waterworks Bureau ■ Contractor: PS Mitsubishi Corporation ■ Pipe Diameter: 1200mm ■ Pushing Length: 36.628m and 133.936m ■ Soil Type: Sandy silt ■ N Value/Gravel Rate/Maximum Gravel Diameter: N=1 to 4, G=0%, φmax=0mm ■ Construction Period: May 2015 to July 2015 (2.5 months) ■ Type of Obstacle: Insurance method, no obstacles *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is an introduction to the construction achievements of the Shinagawa Ward Kitashinagawa MAKP750A main construction project (Sankyo Bridge Phase III). Initially, there was a possibility of steel sheet piles Type III and H-400 existing in the push pipe section, and it was also a river crossing push construction. It was difficult to remove obstacles from the ground, and due to the construction of ultra-soft soil, careful consideration was required. All push pipes used were synthetic pipes that could be connected, and the tunneling machine was equipped with two meandering correction devices for construction. As a result of the construction, there were no steel sheet piles Type III or H-400, and two wooden piles of approximately 250mm were cut. 【Construction Case】 ■ Project Name: Shinagawa Ward Kitashinagawa MAKP750A Main Construction Project (Sankyo Bridge Phase III) ■ Client: Tokyo Gas Co., Ltd. ■ Contractor: Nippon Steel & Sumitomo Metal P&E Corp. ■ Pipe Diameter: 900 ■ Push Length: 40.966m ■ Soil Type: Sandy silt ■ N Value/Gravel Rate/Maximum Gravel Diameter: N=0 G=0% φmax=0mm ■ Construction Period: May 2015 to July 2015 (1.5 months) ■ Type of Obstacles: Wooden piles approximately φ250mm × 2 *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This document introduces the construction achievements of the new tunnel construction for the Otemachi District 2-1 planned route. In carrying out this construction, there was a possibility that underground connecting passages and foundation piles for the Tokyo Metro Marunouchi Line were present in the push pipeline section. The locations of the foundation piles were in a busy urban area with heavy road traffic, and since the burial depth of the push pipeline was very deep, it was necessary to ensure safe construction for both the launch and arrival. In the actual construction, there were no piles, and we cut 6 layers of the arrival shaft liner, 5 H-150mm pipes, and a 1m reinforced concrete wall of the manhole. 【Construction Case】 ■ Project Name: New Tunnel Construction for Otemachi District 2-1 Planned Route ■ Client: Marunouchi Heat Supply Co., Ltd. ■ Contractor: Shimizu Corporation ■ Pipe Diameter: 2600 ■ Pushing Length: 159.601m ■ Soil Type: Silty clay ■ N Value/Gravel Ratio/Maximum Gravel Diameter: N=19 ■ Construction Period: Day and night construction (17.5h) for 4 months (2014.12 to 2015.3) ■ Type of Obstacle: 1m thick reinforced concrete wall of the manhole, 5 H-150 pipes, 6 layers of liner *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This document introduces the construction achievements of the 5th section of the Onjigawa East Drainage Area sewer construction for the fiscal year 2013. It is believed that there are supporting piles (PC piles φ250mm at 3 locations) for the retaining wall of the side road in the push pipe section, and furthermore, the road where the push construction is to be carried out is a major road with heavy traffic, making road regulation difficult. The construction was carried out using the milling mole method, and the PC piles φ250mm at 3 locations were cut. 【Construction Case】 ■ Project Name: Sewer Construction for the 5th Section of the Onjigawa East Drainage Area for Fiscal Year 2013 ■ Client: Yao City, Osaka Prefecture ■ Contractor: Toda Corporation & Bun-Iwa Group Joint Venture ■ Pipe Diameter: 1650 ■ Pushing Length: 325.470m (200R 1 curve) ■ Soil Type: Sandy soil and clayey soil ■ N Value/Gravel Ratio/Maximum Gravel Diameter: N=50 G=0% φmax=19mm ■ Construction Period: Night work (8h) for 5 months (2014.11 to 2015.3) ■ Type of Obstacle: PC piles φ250mm at 3 locations *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This introduces the construction achievements of the Heisei 24 fiscal year Onjigawa East Drainage District Section 14 sewer construction. At this site, it was believed that an H-beam (H-300) was located approximately 5.5 meters from the start of the thrust pipe section. The H-beam, which was an obstacle, was cut diagonally, and after passing through, a second H-beam was similarly cut diagonally about 4 meters later, after which normal excavation was carried out. As a result, two H-beams (H-300) were cut, and the discharge of metal fragments was confirmed. 【Construction Case】 ■ Project Name: Heisei 24 Fiscal Year Onjigawa East Drainage District Section 14 Sewer Construction ■ Client: Yao City, Osaka Prefecture ■ Contractor: Bun-Iwakumi Co., Ltd. ■ Pipe Diameter: 1000 ■ Thrust Length: 229.25m (45R, 70R, 100R×2, 200R 5 curves) ■ Soil Type: Sandy soil and clayey soil ■ N Value/Gravel Ratio/Maximum Gravel Diameter: N=4-35 G=0% φmax=57mm ■ Construction Period: Daytime construction (6h) for 3 months (2015.01 to 2015.3) ■ Type of Obstacle: H-beam H-300, 2 locations *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is an introduction to the construction achievements of the Edo River Left Bank Drainage Area Sewer Pipe Construction Project. During the construction of the lower section (φ1350mm mud water method, executed by another company), there was a hard soil-like obstacle that caused damage to the bit, leading to a design change at the site. To safely carry out the launch and arrival, a pressure-in caisson wall (originally planned to be unreinforced, but actually contained some reinforcement) was cut to L=0.9m on the launch side and L=0.3m on the arrival side. 【Construction Case】 ■ Project Name: Edo River Left Bank Drainage Area Sewer Pipe Construction (Ichikawa Main Line Section 502-2) ■ Client: Chiba Prefecture Edo River Sewer Office ■ Contractor: Hodota Corporation ■ Pipe Diameter: 1350mm ■ Pushing Length: 142.921m ■ Soil Type: Sandy soil and clayey soil ■ N Value/Gravel Ratio/Maximum Gravel Diameter: N=Average 18.5 ■ Construction Period: Daytime construction (8h) (10h during cutting) 2.5 months (2014.12.01 – 2015.2.13) ■ Type of Obstacle: Soil of the pressure-in caisson (Launch side L=0.9m, Arrival side L=0.3m) (Not detected this time, assumed to be H steel of SMW) *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This construction involved the installation of water pipes, where a φ1000 thrust pipe was pushed through, followed by the insertion of a φ800mm water supply pipe. After approximately 161 meters from the start, the first obstacle was cut, and normal thrusting continued for about 7 meters. Subsequently, the second obstacle was cut, allowing normal thrusting to reach the remaining 244 meters. During the approximately 9-meter section crossing the national road, excavation was carried out while injecting chemical agents inside the machine. As a result of the construction, there was no metal reaction from the first obstacle. After injecting chemical agents inside the machine and proceeding with thrusting, a metal reaction from the second obstacle was confirmed, and cutting of the obstacle began, with the discharge of metal fragments being verified. 【Construction Example】 ■ Project Name: Nishi-Nari Branch Pipe (Nishi-Nari) 800mm Water Supply Pipe Installation ■ Client: Osaka City Waterworks Bureau ■ Contractor: Mori-gumi & Hanshin Construction Joint Venture ■ Pipe Diameter: 1000 ■ Thrust Length: 411.65m ■ Soil Type: Sandy Soil, Clayey Soil ■ N Value/Gravel Ratio/Maximum Gravel Diameter: N=10, G=0%, φmax=0mm ■ Construction Period: Day and Night Work (8h) for 4.0 months (2014.2.5 – 2014.5.10) ■ Type of Obstacle: Steel Sheet Pile Type III, 1 location *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This document introduces the construction achievements of the water supply main pipe installation project around Hanjin Town in Sasebo City, Nagasaki Prefecture. After approximately 40 meters of advancement, the first obstacle (steel sheet pile type III) was cut, followed by about 7 meters of normal pushing. Subsequently, the second obstacle (steel sheet pile type III) was cut, allowing for the remaining 15 meters to be reached through normal pushing. This project involved the installation of a water pipe, where a φ900 steel pipe was pushed through, followed by the insertion of a φ600mm ductile pipe. The obstacles (steel sheet pile type III) were used during the construction of the embankment for the Hanjin Bridge and were located on both sides of the river. 【Construction Example】 ■ Project Name: Hanjin Town Surrounding Drainage Main Pipe Installation (No. 6) ■ Client: Sasebo City Waterworks Bureau ■ Contractor: Tanimura Construction & Taniyama Construction Joint Venture ■ Pipe Diameter: 800 (φ900 steel pipe) ■ Pushing Length: 62.00m ■ Soil Type: Gravel mixed with sandy silt ■ N Value/Gravel Ratio/Maximum Gravel Diameter: N=2 G=0% φmax=52mm ■ Construction Period: 2013.11.1 to 13.11.18 (0.5 months) ■ Type of Obstacles: Two locations of steel sheet pile type III *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is an introduction to the achievements of the sewer construction work for the Onjigawa East Drainage Area, Section 42, which was carried out in the fiscal year 2012. Immediately after the start, the existing push pipe, a φ1800mm concrete pipe, was cut diagonally over a distance of 8.21m due to obstacles, and then normal excavation was performed to reach the existing special manhole. At the existing manhole, the head was completely damaged, and the plan was to disassemble and recover everything else. 【Construction Case】 ■ Project Name: Sewer Construction for Onjigawa East Drainage Area, Section 42, Fiscal Year 2012 ■ Client: Yao City, Osaka Prefecture ■ Contractor: Asanuma Corporation ■ Pipe Diameter: 1800mm ■ Pushing Length: 119.86m ■ Soil Type: Sandy Soil, Clayey Soil ■ N Value/Gravel Ratio/Maximum Gravel Diameter: N=13, G=4%, φmax=19mm ■ Construction Period: 2013.06.01 to 2013.08.30 (3 months) ■ Type of Obstacle: φ1800 Concrete Pipe, 8.2m *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This document introduces the construction achievements of the construction work for the Sangenya Chishima main line diversion pipe in Osaka City. Due to the presence of obstacles in the form of wooden piles, forward exploration using electromagnetic waves and excavation management using data loggers were conducted. Since the obstacles were wooden piles, no increase in excavation torque or thrust was observed, and the presence or absence of obstacle cutting was confirmed by the discharge of wood chips. 【Construction Case】 ■ Project Name: Sangenya Chishima Main Line Diversion Pipe Construction (Part 1) ■ Client: Osaka City Construction Bureau ■ Contractor: Kitabume Corporation ■ Pipe Diameter: 800 ■ Pushing Length: 127.61m ■ Soil Type: Sand and Silt ■ N Value/Gravel Ratio/Maximum Gravel Diameter: N=7 G=0% φmax=0mm ■ Construction Period: July 2, 2013 – August 10, 2013 (1 month) ■ Type of Obstacle: Wooden Piles φ150×3 pieces *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is an introduction to the achievements of the new construction work for the Hibiya Route tunnel as part of the Nishishinbashi 1-chome project supply work. After starting, we cut the first obstacle H300 at about 10 meters, and then continued to cut the second and third H300 obstacles at intervals of about 2 meters. We planned to cut the remaining three H300 obstacles before reaching the destination. However, in reality, we only cut up to the third obstacle from the beginning, and we did not encounter the remaining three obstacles (H300). 【Construction Case】 ■ Project Name: New construction work for the Hibiya Route tunnel as part of the Nishishinbashi 1-chome project supply work (Part 1) ■ Client: Marunouchi Thermal Supply Co., Ltd. ■ Contractor: Takeuchi Civil Engineering Co., Ltd. ■ Pipe Diameter: 2000 ■ Pushed Length: 78.30 m ■ Soil Type: Sandy Silt ■ N Value/Gravel Rate/Maximum Gravel Diameter: N=2 G=0% φmax=0mm ■ Construction Period: 2011.12.11 to 2012.2.8 (2 months) ■ Type of Obstacles: H-300, 4 locations, 8 pieces * For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The construction site for the Ise Bay Crossing Gas Pipeline installation encountered the discovery of old stone masonry (large boulders) in addition to results from prior magnetic surveys indicating some metal reactions, leading to the adoption of the milling mole method. During the excavation of the launch shaft, the stone masonry and tetrapods that were unearthed were significantly larger than the nominal diameter of φ1000mm, making cutting very difficult. The thrust pipes also utilized composite steel pipes with rolling prevention features specifically designed for milling. During construction, fragments of large boulders and wire were discovered, and it is believed that the metal reaction was due to this wire, which was likely associated with the large boulders contained in a wire cage. 【Construction Case】 ■ Project Name: Ise Bay Crossing Gas Pipeline Installation (Gas Conduit Construction) ■ Client: Toho Gas Co., Ltd. ■ Contractor: Kajima Corporation ■ Pipe Diameter: 1000 ■ Thrust Length: 68.47m ■ Soil Type: Riprap, Sandy Soil ■ N Value/Gravel Ratio/Maximum Gravel Diameter: N=50 G=80% φmax=1000mm ■ Construction Period: 2011.12.11 to 2012.2.8 (2 months) ■ Type of Obstacle: Wire, Tetrapod Old Stone Masonry (Large Boulders) *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In January 2012, we would like to introduce the achievements of the obstacle removal work that was successfully completed after cutting six steel sheet piles of Type III at a construction site ordered by Kishiwada City, Osaka Prefecture. After a thrust length of 432 meters with a diameter of 1000mm, we encountered the first obstacle approximately 100 meters after starting, followed by six consecutive encounters with obstacles over a distance of about 30 meters, with the remaining 222 meters being pushed through normally. The tunneling machine detected obstacles six times, cut through them six times, and reached the target with high precision using an electromagnetic wave guidance surveying device. 【Construction Case】 ■ Project Name: Kishiwada City Public Sewerage Section 1 Pipe Laying Work ■ Client: Kishiwada City, Osaka Prefecture ■ Contractor: Joto Construction Co., Ltd. ■ Pipe Diameter: 1000mm ■ Thrust Length: 432.34m ■ Soil Type: Sandy gravel ■ N Value/Gravel Ratio/Maximum Gravel Diameter: N=33 G=51% φmax=200mm ■ Construction Period: 2011.12.20 to 2012.3.15 (3 months) ■ Type of Obstacles: Six locations of steel sheet piles Type III *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The underground obstacle-responsive mud-based thrusting method "Milling Mole Method" consists of three devices: a tunneling machine, a special telescopic pipe, and a special injection pipe, which pulverizes and discharges metal obstacles. The special telescopic pipe is used during the cutting of obstacles, allowing the tunneling machine to be pressed against the obstacle and cut at ultra-low speed. The special injection pipe is equipped with facilities for ground improvement at the front of the tunneling machine or the back of the obstacle. Additionally, this method can guide the tunneling machine to the designated position of the vertical shaft. A receiving coil is installed at the designated position inside the arrival shaft, and a system is in place to guide the tunneling machine to that position. Measurements are taken approximately 40 meters before arrival, and the orientation angle of the tunneling machine is calculated and displayed in real-time. [Features] ■ Pulverizes and discharges metal obstacles ■ Guides the tunneling machine to the designated position of the vertical shaft *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The underground obstacle-responsive mud-based thrusting method "Milling Mall Method" explores while pushing forward the metal obstacles ahead of the thrusting cutter. If obstacles are present during excavation, it is possible to detect obstacles approximately 2 meters ahead of the tunneling machine. Additionally, this method allows for ground improvement from inside the tunneling machine both before and after the obstacle. Since cutting through obstacles takes time, the surrounding ground may loosen, potentially affecting nearby underground installations and causing subsidence or uplift on the surface, making ground improvement necessary. The Milling Mall is designed to allow construction from within the tunneling machine in case ground improvement from the surface is not possible. 【Features】 ■ Exploration while pushing forward the metal obstacles ahead of the thrusting cutter ■ Ground improvement from inside the tunneling machine both before and after the obstacle *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Yasuda Engineering Co., Ltd. has been a specialized company in public sewer construction, contributing to the environmental development of the local community since its establishment in 1975. We have pursued sound management and advanced technical capabilities, continuing to make steady progress. In 2001, we acquired the international standard "ISO9001" and expanded into the field of general civil engineering. We aim to be a corporate group capable of continuous innovation in comprehensive construction, including building construction. At Yasuda Engineering Co., Ltd., all employees are united in honing our technical skills and creating a new future. 【Main Business Categories】 ○ Comprehensive construction ○ Pushing construction ○ Planning, design, surveying, construction, management, contracting, and consulting related to comprehensive construction ○ Buying, exchanging, leasing, brokering, and managing real estate ○ Manufacturing, selling, and renting construction machinery and equipment, among others *For more details, please refer to our catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Mud Water Type Mad Max Method" is a large-diameter mud water thrusting method that can handle high water pressure and large gravel. By using the SMC system (Thrust Monitor & Thrust Control System), it has become possible to perform thrusting pipe construction with a diameter ranging from φ800mm to φ3000mm on sharp curves and over long distances. It accommodates a wide range of soil types, including ordinary soil, gravel layers, cobble layers, and soft rock. Additionally, the shape of the bit can be changed. 【Features】 ■ Capable of sharp curve construction (minimum radius of about 15R) ■ By using the SMC system, long-distance construction of over 500m is possible ■ Accommodates a wide range of soil types, including ordinary soil, gravel layers, cobble layers, and soft rock ■ Compatible with standard bits, roller bits, and cutting bits *For more details, please feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Mud Pressure / Earth Pressure Type Mad Max Method" is a construction method that can be applied to cohesive soils, cobble layers, and hard soils. It is systematized from excavation to soil removal and solidification treatment, allowing for continuous operation. Additionally, long-distance construction is possible with the aid of supplementary systems. Furthermore, it requires minimal surface equipment and can be executed in narrow yards. By disassembling and transporting the screw conveyor, it can be used in small shafts. 【Features】 ■ Applicable to cohesive soils, cobble layers, and hard soils ■ Systematized from excavation to soil removal and solidification treatment ■ Requires minimal surface equipment, allowing for construction in narrow yards ■ Enables input in small shafts by disassembling and transporting the screw conveyor ■ 100% recovery of equipment is possible by using a tunneling machine for reaching manholes *For more details, please feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration