1~45 item / All 354 items

Displayed results

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us Online1~45 item / All 354 items

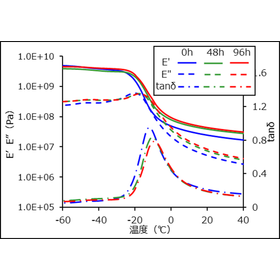

This introduces the evaluation of thermally degraded rubber using dynamic viscoelastic measurements. A constant temperature bath capable of circulating air within the chamber was used as a suitable device for thermal degradation testing, heating NBR rubber and EPDM rubber at 100°C for a specified duration. The changes in viscoelastic behavior due to heating time were investigated. For both types of rubber, as the heating time increased, the tanδ (= E"/E') peak shifted towards the high-temperature side, and a decrease in peak value was observed. It is believed that the loss of rubber elasticity and the decrease in elastic modulus resulted in the Tg shifting towards the high-temperature side. By measuring dynamic viscoelasticity, it becomes possible to confirm the changes in physical properties associated with material degradation and to gain insights into structural changes. Additionally, conducting other chemical analyses can clarify more specific changes in chemical structure. 【Test Overview】 ■ A constant temperature bath capable of circulating air within the chamber was used ■ NBR rubber and EPDM rubber were heated at 100°C for a specified duration ■ Changes in viscoelastic behavior due to heating time were investigated *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We conducted a "moisture and heat resistance test for adhesives" to investigate changes in adhesive strength due to the effects of moisture and heat. The test specimens were placed in a constant temperature and humidity testing machine, and after 500 hours, they were removed to measure the tensile shear adhesive strength. It is presumed that the adhesive strength decreased due to the swelling of the adhesive in a high-temperature and high-humidity environment. We can conduct various environmental tests and strength tests on a variety of materials, not limited to adhesives. Additionally, we also provide chemical analysis to clarify degradation mechanisms. [Test Results] ■ The adhesive strength (breaking stress) of samples placed in a humid heat environment for 500 hours significantly decreased. ■ From the stress-strain curve of the tensile test, a decrease in the modulus of elasticity for both adhesives A and B was confirmed. ■ It is presumed that the adhesive strength decreased due to the swelling of the adhesive in a high-temperature and high-humidity environment. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Regarding the NMC reagent, an evaluation of the valence of metal oxides was conducted through state analysis using XPS. Qualitative analysis was performed on commercially available NMC reagents, yielding values for the NiMnCo ratio that are close to the specifications of the reagent. Additionally, F and C, which are believed to originate from the binder components, were also detected. 【Analysis of NMC Reagent (Partial)】 ■ The main oxides of Ni, Mn, and Co are inferred to be NiO (Ni2+), MnO2 (Mn4+), and Co3O4 (a mixed valence of Co2+ and Co3+). ■ C, O, and F show peak shifts consistent with organic compounds believed to originate from the binder. ■ Peak assignments were inferred based on various literature and databases. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Here is an example of failure analysis of chip resistors where abnormalities were observed. Upon investigating the cause of malfunction in the polishing table, abnormalities were confirmed in the chip resistors on the relevant board. Surface observation revealed abnormalities in the chip resistors, and it appeared that the protective film was melted. Elemental analysis using EDX detected elements such as Al and Pb from the abnormal area, raising suspicions that the undercoat layer may be exposed. Next, cross-sectional samples were prepared through mechanical polishing, and analysis was conducted using SEM/EDX, which showed that the protective film and resistive material appeared to be melted. At Aites, we consider and propose processing, pretreatment, observation methods, and combinations tailored to the observation objectives and the composition and structure of the samples based on our accumulated know-how. Please feel free to contact us for consultations. [Analysis Content] ■ Surface Observation ■ Cross-sectional Observation *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We will introduce a case where the rebound and vibration absorption properties of rubber materials were evaluated using dynamic mechanical analysis (DMA). In the "Comparison of Vibration Absorption of Rubber (Temperature Dispersion Measurement)," dynamic mechanical analysis was conducted using two types of rubber materials. Rubber A is considered to have superior vibration absorption properties (lower rebound) than Rubber B, with larger E" and tanδ in temperature ranges above -10°C. In the "Comparison of Vibration Absorption of Rubber (Frequency Dispersion Measurement - Master Curve)," the dynamic mechanical properties of Rubber A and B were compared across frequencies. By creating a master curve, it is also possible to predict viscoelastic behavior in frequency ranges that cannot be measured directly. 【Measurement Details】 ■ Comparison of Vibration Absorption of Rubber (Temperature Dispersion Measurement) - Rubber A is considered to have superior vibration absorption properties (lower rebound) than Rubber B, with larger E" and tanδ in temperature ranges above -10°C. ■ Comparison of Vibration Absorption of Rubber (Frequency Dispersion Measurement - Master Curve) - Rubber A is considered to have superior vibration absorption properties than Rubber B, with larger tanδ over a wider frequency range. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company conducts consistent analysis from reliability testing to failure analysis. This allows us to confirm whether the samples meet the specifications, as well as to identify and observe the defective areas of failed samples. We propose and implement tests and analyses tailored to our customers' requests and objectives, assisting from cause investigation to problem resolution. Please feel free to contact us when you need our services. 【Analysis Flow】 ■ Specification confirmation of semiconductor devices through reliability testing ■ Identification of defective areas and observation of failure locations using TEM ・ Identification of defective areas through EMS/OBIRCH analysis ・ Observation of failure locations using TEM *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We will introduce a case study comparing cross-section preparation methods on the surface coating layer of a golf ball and observing the effects of heat from CP processing. There are two layers of coating on the outermost layer of the cover layer, and we conducted a comparison of cross-section preparation methods using this coating layer. SEM observations were performed on cross-sections prepared using three different methods. While cross-section preparation of soft materials is effectively done using cross-section ion milling (CP), the physical properties may change due to the heat generated during CP processing. In such cases, cross-section preparation using cryo-CP, which mitigates the effects of processing heat through cooling, is effective. 【Cross-section Preparation Methods】 ■ Mechanical Polishing ■ CP ■ Cryo-CP (-50°C) *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This document introduces examples of visualizing the internal state of capsules in three dimensions and obtaining elemental information through EDX analysis of powders. In the X-ray CT analysis, it was observed that there were slight air gaps inside the capsule, and it was visually confirmed that the particle size was not uniform, with some larger particles included. In the SEM-EDX analysis, elemental analysis was conducted on any particles contained within. At an acceleration voltage of 15 kV, carbon (C), oxygen (O), as well as calcium (Ca), chlorine (Cl), iron (Fe), phosphorus (P), and sodium (Na) were detected. [Analysis Details] ■ X-ray CT Analysis: X-ray transmission observation of capsule preparations ■ SEM-EDX Analysis: Elemental analysis of any particles contained within *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce the dynamic viscoelasticity measurement of CFRP conducted by our company using the bending mode. When performing dynamic viscoelasticity measurements using DMA, CFRP is generally highly elastic, and it is considered that measurements using the bending mode are suitable due to its applications. The deformation modes of DMA can measure in any mode as long as the size requirements are met, but it is ideal to select appropriate conditions based on the material's shape, elastic modulus, and measurement objectives. If you have a subject for which you would like to measure dynamic viscoelasticity, please feel free to consult us. 【Measurement Modes】 ■ Tension ■ Compression ■ Bending (two-support/one-support/three-point) ■ Shear *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company will introduce the FEI "Talos F200E" transmission electron microscope system. Compared to conventional models, the resolution for TEM and STEM has improved, and performance has been significantly enhanced, including the capability for EDS analysis with four detectors. Additionally, it is equipped with Drift Corrected Frame Integration (DCFI), which allows for the integration of multiple frames while correcting for drift. 【Specifications (excerpt)】 ■ Acceleration Voltage: 200kV, 80kV ■ TEM Information Limit: ≦0.11nm ■ STEM Resolution: ≦0.14nm ■ Drift Corrected Frame Integration (DCFI) ・Integrates multiple frames while correcting for drift *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Aites Co., Ltd., we conduct "Poisson's ratio measurement." Poisson's ratio is the ratio of longitudinal strain to lateral strain that occurs when a load is applied to an object, and it is necessary for strength calculations of materials. In the downloadable materials, we introduce the results of attaching strain gauges to test specimens, applying tensile loads using a universal testing machine, and examining the longitudinal and lateral strains obtained from the strain gauges. Please feel free to download and take a look. 【Measurement Examples】 ■ Measurement using strain gauges ■ Measurement using video extensometers *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

It is a measuring instrument that can non-contact measure surface shapes such as concavities, undulations, and surface roughness. We will introduce "Heating Deformation Observation" using a 3D shape measuring device. First, we acquire a 3D texture image at room temperature, and then we acquire a 3D texture image in a heated state. By overlaying the texture images before and after heating and checking the differential texture image and cross-sectional profile, it can be seen that the substrate in the heated state has higher ends and a lower center compared to the room temperature state. 【Features】 ■ It is possible to visualize and confirm shape changes during heating. ■ Depending on your preferences, it is possible to create profiles for temperature rise speed, waiting time, and temperature settings. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a case where cross-sections were created and observed for the adhesive parts of pull-back car tires using different methods. Upon conducting SEM observations of the created cross-sections, fillers present within the rubber were confirmed. It was found that the dispersion state of the fillers and the appearance of the adhesive interface were not clear with liquid nitrogen fracturing or mechanical polishing. In contrast, cross-sections created by cryo ion milling allow for a clear observation of the dispersion state of fillers contained within the rubber and the appearance of the adhesive interface with the plastic substrate. 【Cross-section Preparation Methods】 ■ Liquid Nitrogen Fracturing (-196°C) ■ Mechanical Polishing ■ Cryo CP (-150°C) *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce the "Tensile Property Evaluation using a High-Extension Flexible Material-Compatible Extensometer" that we offer. Tensile tests of NR rubber were conducted using both contact-type (high-extension, soft material compatible) and non-contact type (video) extensometers, and the results were compared. To accurately determine strain in tensile tests, it is necessary to select an appropriate extensometer and testing conditions based on the target material and measurement purpose. We will provide suggestions tailored to your consultation needs. 【Extensometer Comparison】 ■ Contact Type (High-Extension, Soft Material Compatible) - Suitable for materials with large extensions - Not suitable for brittle or easily deformable materials - Not usable in constant temperature baths ■ Non-Contact Type - No material constraints *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We conducted measurements to reconfirm the temperature of heat generation during curing, following the change to a non-toxic epoxy resin. When using a large amount of resin, we apply heat generation prevention treatment for resin embedding. Without this treatment, the temperature can rise up to 138°C during curing. However, by applying heat generation prevention treatment even with a large amount of resin, we were able to keep the heat generation during curing within 30°C. [Measurement Results] ■ Without heat generation prevention treatment for a large amount of resin (large container) - Heat generation reached up to 138°C during curing ■ With heat generation prevention treatment for a large amount of resin (large container) - Heat generation during curing was kept within 30°C *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company conducts "Rubber Thermal Aging Tests" that help evaluate the properties of materials in actual usage environments. Using a method compliant with JIS K6257 (Method for Determining Thermal Aging Characteristics of Vulcanized Rubber and Thermoplastic Rubber), rubber test pieces are suspended in a gear oven to create samples with varying heat treatment times. Additionally, we perform tensile tests on heated natural rubber (NR) to investigate changes in mechanical properties, while simultaneously measuring hardness. We also examine changes in rubber characteristics, confirming that rubber elasticity is lost and it becomes harder with heating. [Physical Property Evaluation] - Heating Temperature: 120°C - Tensile Test: Universal Testing Machine - Hardness Measurement: Micro Rubber Durometer *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our "Component Analysis of Organic Substances" commonly utilizes FT-IR and GC/MS. In FT-IR measurements, it is possible to analyze the main components of organic substances by comparing the IR spectra of known substances. Additionally, if you wish to analyze not only the main components of unknown substances but also trace amounts of organic substances such as additives, we recommend conducting GC/MS measurements. 【Features】 <FT-IR Measurement> ■ Capable of analyzing the main components of organic substances ■ Some inorganic substances can also be analyzed *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce the "Substrate Deformation Observation" using a 3D shape measuring machine. By applying pressure to a PCB substrate, referencing the bending tests of plastics and PCB substrates, we measure the changes using a 3D shape measuring machine (VR-6200). Since the measurement results can be confirmed with a color palette and line profile, it is possible to visually verify the shape and amount of deformation caused by the applied pressure. 【Features】 ■ Measurement results can be confirmed with a color palette and line profile ■ It is possible to visually verify the shape and amount of deformation caused by the applied pressure *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce the "Tracking Camera Cross-Section Observation" using mechanical polishing. Regarding the structure of the tracking camera components, the lens can be confirmed when viewed from above, and while it is not clearly visible in the X-ray image, the lens is incorporated into the convex part. Additionally, the cross-sectional structure is the same as that of the RGB sensor, featuring a back-illuminated CMOS structure. However, since color information is not required for the tracking camera, there is no color filter layer. A jagged uneven shape was observed on the surface of the photodiode. 【Features】 ■ The cross-sectional structure is the same as that of the RGB sensor, featuring a back-illuminated CMOS structure. ■ There is no color filter layer since color information is not required for the tracking camera. ■ A jagged uneven shape was observed on the surface of the photodiode. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Aites Co., Ltd., we conduct "NMR analysis of liquid crystal compounds." NMR is an analytical method that reveals the connections between atoms that make up a molecule, and it is used alongside mass spectrometry and infrared spectroscopy for determining the structure of compounds. In the downloadable materials, we highlight the 1H NMR, 13C NMR, and DEPT measurements of 4-butoxy-4'-cyanobiphenyl (CAS number 52709-87-2), which is used as a liquid crystal component, and introduce the information obtained from NMR. Please feel free to download and take a look. [Measurement Examples] ■ 1H NMR measurement ■ 13C NMR measurement and DEPT measurement ■ Other NMR measurement techniques *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce our "Appearance Observation and Measurement Services." We are equipped with a variety of devices to meet your needs, including appearance observation before and after reliability testing, solder joint observation, as well as dimensional measurements and surface roughness measurements of various components. You can also leave the pre-observation processing to us. Our company has IPC-A-610 certified IPC specialists on staff. We provide assistance and consultation for observations in accordance with international standards, addressing various concerns related to observations. 【Equipment】 ■ VHX-X1 ■ VHX-5000 ■ VR-6200 ■ VK-X200 *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At our company, we created cross-sections of the CMOS image sensor components accompanying the VR goggles manufactured by Company A through mechanical polishing in their original state, and conducted structural observations of the CMOS sensor components. During the observation of the sensor component structure and sensor surface, we removed the glass filter and observed the surface of the CMOS sensor, where it was noted that the arrangement of the color filters was in a configuration known as a Bayer filter. In addition to mechanical polishing, methods for creating cross-sections include processing with ion beams such as FIB and CP, as well as microtome methods. Consultations are free, so please feel free to contact us if you are unsure about the cross-section creation methods. [Overview] ■ Observation of sensor component structure and sensor surface ■ Cross-section creation by mechanical polishing ■ SEM observation of the sensor chip surface layer *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to present the results of strain measurements conducted by attaching strain gauges and thermometers to the surfaces of power modules, one mounted on a circuit board and the other not mounted. In the mounted module, a slight delay in temperature change was observed, which correspondingly resulted in a delayed change in strain. This is believed to be due to the slower heat transfer to the module when it is mounted. 【Test Overview】 ■ Strain Gauge Used - Foil strain gauge for composite materials: compatible linear expansion coefficient 1x10^-6, base 15x5mm ■ Test Conditions - Hold at -40℃ for 3 hours → 15℃/min → hold at 80℃ for 3 hours * 5 cycles * For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At AITES Co., Ltd., we provide a multifaceted technical service for evaluation tests of printed circuit boards (mounted boards) equipped with electronic components. We conduct reliability tests, solder joint observations, whisker observations, and cross-sectional observations. We assist with observations in accordance with international standards, offer consultations, and address various concerns regarding observations. Additionally, we offer services such as X-ray observations, appearance inspections, and shape measurements, so please feel free to consult us when needed. 【Service Contents】 ■ Reliability Testing ■ Solder Joint Observation ■ Whisker Observation ■ Cross-Sectional Observation *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We will introduce the analysis of organic and inorganic composite materials using FT-IR and EDX. FT-IR measurements were conducted on the glossy and non-glossy areas of the surface of the PET bottle label, revealing that the IR spectra differed between the glossy and non-glossy areas. Additionally, SEM-EDX measurements were performed on the glossy and non-glossy areas, and the EDX spectrum and backscattered electron image showed that the non-glossy area contained sulfur (S) and barium (Ba), which were not detected in the glossy area. [Analysis Details] ■ Organic analysis using FT-IR - FT-IR measurements on the glossy and non-glossy areas of the PET bottle label surface ■ Inorganic analysis using SEM-EDX - SEM-EDX measurements on the glossy and non-glossy areas *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce the composition analysis of active materials in LIB cathode materials using ICP emission analysis. The cathode material of lithium-ion batteries (LIB) is one of the important components that influence the battery's voltage and energy density, and the composition of the cathode material significantly affects the battery's performance. ICP emission analysis can analyze which elements are contained in liquid samples and in what quantities. 【Features】 - Qualitative and quantitative analysis of approximately 70 types of elements is possible. - Applicable to various analyses, including qualitative and quantitative analysis of additives and impurities contained in samples, as well as quantitative analysis of substances regulated by RoHS directives. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We will introduce the three-dimensional reconstruction of failure locations using the Slice & View function of FIB-SEM. Continuous SEM images of the structure are obtained, and the resulting images are corrected for positional misalignment between SEM images and visualized in three dimensions using three-dimensional construction software (Avizo). By combining the position identification technique for cross-sectioning the failure location with the Slice & View function, it is possible to obtain continuous SEM images that retain the defective state and include information before and after the abnormal area. [Contents] ■ About Slice & View and three-dimensional reconstruction ■ Continuous SEM observation and three-dimensional reconstruction of failure locations identified by OBIRCH *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Aites Co., Ltd., we conduct "optical film analysis." Optical films used in smartphones and other devices have various functions depending on their structure and materials. We can investigate the transmission characteristics of anti-peeping films using angle-variable spectrophotometry and analyze the mechanism of function manifestation through cross-sectional observation and Raman analysis. 【Features】 ■ Measurement of optical properties ■ Analysis of the mechanism of function manifestation *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company conducts environmental testing using a constant temperature and humidity chamber with a front glass window and a camera, allowing us to capture and monitor the operational status, such as screen displays. During environmental testing using equipment like constant temperature and humidity chambers, monitoring the condition of the test subjects using loggers for parameters like voltage, current, resistance, and temperature is widely practiced. For samples where monitoring with loggers is difficult, we combine a constant temperature and humidity chamber equipped with a front glass window option, a camera, and monitoring software to conduct environmental tests while capturing and monitoring the condition of the testing equipment. [Example of monitoring an LCD panel] - Interval shooting at regular intervals - Motion detection shooting that captures images when changes in condition are detected - Monitoring of indicator lamps is also possible *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We will introduce an example of the analysis of compounds formed at the interface between Sn-Ag-Cu solder and NiP pads. At the interface between NiP pads and Sn-Ag-Cu solder, compounds such as (Ni,Cu)3Sn4 and (Cu,Ni)6Sn5 grow, and surface analysis using EDX shows the distribution of Ni, Cu, and Sn within these compounds. The EBSD method is an analytical technique based on the crystallographic information of the sample. By combining it with elemental analysis using EDX, it is possible to estimate the composition, and in some cases, analysis can be performed using the crystallographic data of Ni3Sn4 and Cu6Sn5 as substitutes. 【Overview】 <Elemental Analysis by EDX> ■ Surface analysis shows the distribution of Ni, Cu, and Sn within the compounds. <Crystallographic Orientation Analysis by EBSD> ■ By combining it with elemental analysis using EDX, it is possible to estimate the composition. ■ In some cases, analysis can be performed using the crystallographic data of Ni3Sn4 and Cu6Sn5 as substitutes. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce the results of our investigation into the behavior of strain during moisture absorption and drying using strain gauges. It was observed that the material expands when absorbing moisture and contracts back to its original state when dried, with the strain returning to the condition prior to moisture absorption. Regarding FR-1, it is presumed that the material did not return to its original state due to changes in its chemical structure caused by hydrolysis. 【Test Overview】 ■ 85℃ 50% ⇒ 85℃ 85% ⇒ 85℃ 50% ■ Test Materials - FR-1 Paper Phenolic (single-sided board) - FR-4 Glass Epoxy (single-sided board) ■ Strain Gauge ■ Foil Strain Gauge for Composite Materials *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce our "Microscopic FT-IR Imaging Measurement." It allows for the visualization of the distribution of substances as a two-dimensional image within a specified plane. It becomes possible to evaluate changes in the distribution of substances that are difficult to assess with regular point measurements through visible images. [Analysis Suitable for Imaging Measurement] ■ Evaluation of the diffusion state of substances (assessing the mixing of substances in a mixture, identifying the locations of impurities, etc.) ■ Evaluation of molecular structural changes (assessing the degree of oxidation from the surface to the interior of resin products, etc.) ■ Qualitative analysis of micro foreign substances that are difficult to sample *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We offer the "CP Processing Device Arblade5000_Wide Area Cross-Section Milling." The "Arblade5000" enables extensive processing by combining a high milling rate with wide area cross-section milling capabilities. With the wide area cross-section milling holder, the milling width can be expanded up to 10mm, making it effective for electronic components that require wide area milling. 【Features】 ■ Approximately twice the width of processing is possible ■ The previously localized observation range can be significantly expanded ■ Equipped with a cooling temperature adjustment function to control temperature rise due to ion beam irradiation ■ The observable range is approximately 8mm *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce our "IOL testing of discrete semiconductors." Under normal temperature conditions, we repeatedly turn the power ON/OFF, applying stress to the device due to temperature changes caused by the device's own heat generation during operation. During the power OFF period (cooling), forced cooling is also performed using a fan. 【Adjustment Conditions】 ■ Temperature Rise: 125℃ ■ Heating Time: 5 minutes ■ Cooling Time: 5 minutes ■ Fan Operating Time: 2 minutes *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We will introduce the observation of metal structures through chemical treatment. By performing chemical treatment on metal samples, it is possible to clearly observe the metal structure. Observing the structure can confirm the condition of the sample and the history of applied heat and stress, providing clues about the quality of the product and any defects based on the structural shape. In the published catalog, you can find details on the observation of metal structures, such as the macrostructure of aluminum plates and the soldered parts of copper terminals. Additionally, we offer other services such as cross-sectional observation and various analysis services. Please feel free to contact us if you have any requests. [Published Content] - Macrostructure of aluminum plates - Soldered parts of copper terminals - Brass screws - Welded parts of SUS rods *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In "Microscopic FT-IR," there are three main measurement methods: "transmission method," "reflection method," and "ATR method." In "Microscopic FT-IR," which combines FT-IR with an optical microscope, it is possible to measure small substances of about tens of micrometers that are difficult to measure with conventional FT-IR, using an aperture (field stop). While the transmission method is the basic measurement method in microscopic FT-IR, the reflection method or ATR method may be more suitable depending on the shape of the sample and the feasibility of sampling. 【Characteristics of Measurement Methods】 ■ Transmission Method - Infrared light is irradiated onto the sample, and the transmitted light is measured. - Information is obtained from the thickness of the material that the infrared light has passed through. ■ Reflection Method - Infrared light is irradiated onto the sample, and the reflected light is measured. - Information about the surface of the sample is obtained. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce an example of "observation of semiconductors by mechanical polishing" conducted by our company. While there are advantages and disadvantages, it is possible to create cross-sections with mechanical polishing that are comparable to those made by FIB or CP. Based on years of accumulated know-how, our company will propose the most appropriate processing methods according to the observation purpose, sample composition, and structure. If you have any concerns, please feel free to contact us at the information below. 【Observation Examples】 ■ Semiconductor_Si ■ Compound Semiconductor_GaN ■ Compound Semiconductor_GaP ■ Compound Semiconductor_GaAs *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce the "strain measurement in thermal shock testing" conducted by our company. A sample with a strain gauge attached was set up in the thermal shock testing device, and the wiring of the strain gauge was connected to an external data logger to record strain data in real-time during the test. For two types of copper-clad laminates, the strain behavior during the thermal shock test was observed, and it was noted that significant strain occurred with temperature changes. It was found that FR-1 exhibited greater strain compared to FR-4. [Test Conditions] ■ Temperature Cycle: -30°C to 120°C ■ Exposure Time at Each Temperature: 30 min ■ Test Materials - FR-1 Paper Phenolic (double-sided) - FR-4 Glass Epoxy (double-sided) ■ Strain Gauge: Foil strain gauge for printed circuit boards *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a case of particle size measurement of cathode active materials using laser diffraction conducted by our company. In air or liquid, laser light is irradiated onto the particles, and the angular dependence of the intensity of the light scattered by the particles is measured. By measuring the angular dependence of the scattered light intensity, the particle size distribution (particle size distribution) is calculated from the data. Using commercially available reagents as samples, measurements were conducted in a dry state without dispersing in a solvent. The particle size measurement results for NMC oxides showed a monodisperse state with particle sizes below several tens of micrometers, and the median diameter was calculated to be 12 micrometers. [Case Overview] ■ Measurement Method ・Dry method ■ Particle Size Measurement Results for NMC Oxides ・Monodisperse state with particle sizes below several tens of micrometers ・Median diameter is 12 micrometers *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce an example of cross-sectional observation of mounted components conducted by our company. Using commercially available computer circuit boards, we observed the solder joints of mounted components and the internal structures of the components with a metal microscope. The observation modes of the metal microscope include bright field observation, dark field observation, and polarized light observation, among others. Additionally, there are observations using transmitted light, and the observation mode is selected according to the sample. By conducting cross-sectional observations before and after reliability testing, we can evaluate the reliability of the product. When observing, it is important to select an appropriate "observation mode" to clearly capture the condition of the solder joint interface and defects such as cracks. [Case Overview] ■ Using commercially available computer circuit boards ■ Observing the solder joints of mounted components and the internal structures of the components with a metal microscope ・Observation modes: bright field observation, dark field observation, polarized light observation, etc. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce the Poisson's ratio measurement conducted by our company. Poisson's ratio is the ratio of longitudinal strain to lateral strain that occurs when a load is applied to an object, and it is necessary for strength calculations of materials. We can accommodate Poisson's ratio measurements and strength measurements through tensile testing. Please feel free to consult with us. 【Measurement Examples】 ■ Measurements using a tensile testing machine ■ Strain measurement results and Poisson's ratio calculation results *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce our service for "Cross-sectional Observation of Various Mounted Components on Circuit Boards." Inside various electronic devices around us, there are circuit boards equipped with electronic components. When observing a mounted circuit board, it becomes clear that numerous components are densely soldered together, and it is necessary to confirm that the components are properly joined, as improper connections can lead to malfunction. Please contact us if you are considering observations or cross-sectional examinations before and after reliability testing. 【Examples of Observations (Partial)】 ■ Ceramic Capacitors ■ Transistors ■ Chip Resistors ■ QFP ■ Connector Pins *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce our "Chemical Analysis On-Demand Service." When conducting component analysis of foreign substances or stains on products, it is important to determine whether organic analysis or inorganic analysis is more suitable, and which specific analysis method is best among organic and inorganic options. We provide a comprehensive service for customers who are struggling with the selection of analysis methods. Since each analysis device can measure different targets, it is necessary to choose a method that fits the purpose based on the information available. 【Features】 ■ Only data for which results have been obtained will be reported ■ Results will be reported for up to 2 methods ■ If you wish to receive results for more than 3 methods, additional costs will be incurred *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We thoroughly evaluate and verify FPD from various angles. In structural analysis, we assess FPD products and products incorporating advanced technologies for any potential issues in characteristics and structure, and we provide reports. In defect analysis, we approach and investigate the causes of product defects in increasingly sourced overseas products via the shortest route. Additionally, in reliability testing, we propose suitable reliability testing methods and conditions based on our extensive know-how, tailored to the customer's objectives and needs. 【Our Strengths】 ■ Problem-Solving Ability - Proposal of analytical methods familiar with the LCD manufacturing process ■ Investigative Ability - Skilled insight and advanced, sub-micron level fine sample processing technology ■ Specialized Equipment - Consideration using a combination of diverse analytical instruments *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We will introduce the observation of the shape of conductive particles in COG implementation. ICs and liquid crystal panels are implemented using the COG method with ACF (anisotropic conductive film). A resin ball is used as the core, and a metal layer (such as nickel or gold) is deposited on its surface for conductivity. During connection, the particles deform appropriately to electrically connect the IC and the panel. To confirm the degree of particle deformation and the connection state, cross-sectional observations were conducted, revealing that the amount of particle deformation was "medium," indicating an appropriate level of deformation. By examining the deformation of conductive particles from both the planar and cross-sectional perspectives, we can explore the correlation with display defects. Please feel free to contact us for any inquiries regarding panel-related issues. [Summary] ■ In implemented ICs, slight "warping" or "tilting" can cause differences in particle deformation between the edges and the center, potentially leading to display defects. ■ By examining the deformation of conductive particles from both the planar and cross-sectional perspectives, we can explore the correlation with display defects. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration