Surface modification technology using megahertz ultrasound - Relaxation and homogenization treatment of surface residual stress through nonlinear oscillation control - Consulting support available.

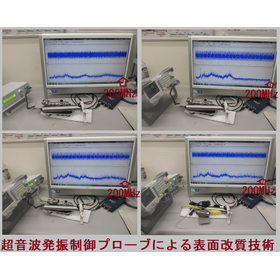

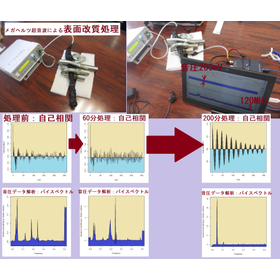

The Ultrasonic System Research Institute has made it possible to apply measurement, analysis, and control technology related to the propagation state of megahertz ultrasonic waves to the surface elastic waves of target objects, achieving dynamic control for the relaxation and uniform treatment of surface residual stress.

With this technology for relaxing and uniformizing surface residual stress, improvements in fatigue strength against metal fatigue have been realized, along with increased efficiency in subsequent processes (various coatings). In particular, by achieving a propagation state of over 700 MHz to the target object under ultrasonic sweep oscillation conditions (below 20 MHz, below 10 W), a uniform surface treatment has been realized that was not possible before.

We have confirmed a wide range of effects on various types of metal parts, resin parts, powder materials, and more.

This is a new surface treatment technology using ultrasound, which, including the general effects based on acoustic properties, can be utilized and developed as a unique operational technology with significant characteristics for the development of new materials, stirring, dispersion, cleaning, chemical reaction experiments, and more.

We offer this technology as a consulting service.

In April 2024, we developed optimization technology for resonance phenomena and nonlinear phenomena.

Inquiry about this news

Contact Us OnlineMore Details & Registration

Details & Registration

Related Documents

Related Links

Surface modification technology using ultrasonic probes

Ultrasonic "Sound Pressure Measurement and Analysis Device (Ultrasonic Tester NA)"

Related product

Related catalog(14)