Mast Drilling System Air Rotary Method Construction Case Studies

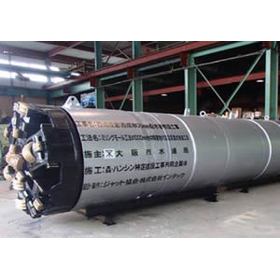

Introduction of construction examples of the environmentally friendly large-diameter drilling method "Mast Drilling System."

We would like to introduce examples of the environmentally friendly large-diameter drilling method, the "Mast Drilling System." The "Mast Drilling System" features characteristics such as "no industrial waste generation," "no noise or vibration," and "no dust generation." The "Mast Drilling System" was registered in 2008 in Wakayama Prefecture as "Kensanpin." 【Case Examples】 ○ Construction Location: Kishu Town, Wakayama Prefecture → There are challenges such as the inability to use mud water for drilling within the river. ○ Construction Location: Nogami Town, Wakayama Prefecture → There are challenges such as the need to reduce the impact of noise and vibration due to proximity to residential areas. For more details, please contact us or download the catalog.

- Company:タニガキ建工 紀の川営業所

- Price:Other

![[Milling Mall Construction Method Case Study] Kishiwada City](https://image.www.ipros.com/public/product/image/089/2000367631/IPROS5589357986667498783.jpg?w=280&h=280)

![[Milling Mall Method Construction Case] New Tunnel Construction for the 2-1 Planning Route in the Temachi Area](https://image.www.ipros.com/public/product/image/0d1/2000367699/IPROS1908266368131029686.jpg?w=280&h=280)