Super Soil L2 for Civil Engineering: Lightweight Fill Material

Super Sol L2

For reducing soil pressure and improving weak ground! Lightweight and easy to work with glass foam material.

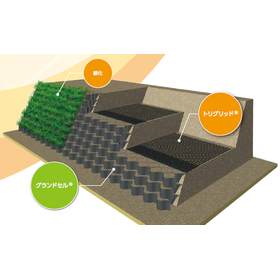

In earthworks within the civil engineering industry, lightweight, drainage capability, and workability are essential. Particularly for embankments on soft ground or around underground structures, reducing soil pressure is crucial, and shortening construction time is also a challenge. Super Sol L2 reduces soil pressure due to its lightweight and enhances ground stability through its drainage properties. Additionally, its ease of construction contributes to shortening the construction period. 【Application Scenarios】 - Embankments over underground structures - Backfilling behind retaining walls - Embankments on soft ground 【Benefits of Implementation】 - Reduction of soil pressure - Shortening of construction time - Improvement of workability

Inquire About This Product

basic information

【Features】 - Lightweight: 1/5 to 1/7 the weight of ordinary soil - Drainage: Excellent drainage properties - Workability: Easy installation through leveling and compaction - Safety: Made from natural waste glass - Versatility: Usable in distorted terrains and narrow spaces 【Our Strengths】 A reliable and safe product supply system provided by 17 manufacturing companies that are members of the Glass Foam Material Business Cooperative.

Price information

Design unit price: 18,000 yen/m3. It may vary depending on the quantity, delivery date, and delivery location, so please feel free to contact us.

Price range

P2

Delivery Time

※The delivery date may vary depending on the quantity, so please feel free to contact us.

Applications/Examples of results

- Roadbed and embankment on soft ground National Route 9 Bypass Road Interchange Improvement Project Kure City Bridge Maintenance Project - Backfilling of structures such as retaining walls and bridge abutments National Route 13 Intersection Improvement Project National Route 375 Bypass Road Improvement Project - Foundations of structures on soft ground Truck Scale Installation Project (Private) - Backfilling of structures and underground installations Tokyo Water Reclamation Center Seismic Reinforcement Project - Elevation Platform Elevation Project Restaurant Kitchen Elevation Project (Private) - Drainage materials for grounds, subsurface drainage materials Fukuoka City Public Middle School Ground Renovation Project Naha City Private High School Sports Field Development Project (Private) - Drainage base materials for rooftop greening and upper structure greening JR Shinjuku Station West Exit Fountain Area Renovation Project

catalog(4)

Download All CatalogsCompany information

"Super Sol," made by crushing and sintering waste glass, is a lightweight material with countless holes, forming a porous structure. It is an artificial lightweight stone with an irregular shape and a particle size of 2 to 75 mm. There are products with varying specific gravities and water absorption rates to suit different applications. Composed of soil components, it is an eco-friendly product with an eco-mark. **Features of Super Sol:** - **Lightweight:** It is 1/6 to 1/5 the weight of soil, with a proven track record as a lightweight fill material. By combining it with crushed stone, the unit weight can be controlled between 4 kN/m³ and 11 kN/m³. - **Drainage:** It can be used as a drainage material in civil engineering and greening projects. - **Aeration and Water Retention:** It can be used as an inorganic soil amendment for greening. - **Workability:** Its lightweight nature makes it easy to handle, facilitating construction in uneven terrains and confined spaces. Like crushed stone, it can be installed through leveling and compaction without the need for curing periods or special techniques. - **Stability:** Being mineral-based and inorganic, it is physically and chemically stable, with no corrosion. - **Safety:** As it is made from naturally derived glass, Super Sol is composed of soil components, making it a highly safe material for the surrounding environment.

![[Super Sol Construction Case] Example of Filling the Step at the Top of A1 EPS](https://image.www.ipros.com/public/catalog/image_generated/01/085/369060/369060_IPROS722809844448321707_1.jpg?w=120&h=170)

![Glass Foam Material Business Cooperative Association [Organization Overview]](https://image.www.ipros.com/public/catalog/image/01/b4c/378394/IPROS4387132434147655772.jpeg?w=120&h=170)

![[Super Sol Construction Case] Example of Arch Culvert Protection](https://image.www.ipros.com/public/product/image/158/2000252452/IPROS8970663017331780390.jpg?w=280&h=280)

![[Construction Examples] FCB Method, JR Bubble Mortar Embankment, etc.](https://image.www.ipros.com/public/product/image/7d8/2001210420/IPROS11561855022477151491.jpeg?w=280&h=280)

![[Disaster Recovery Construction Case] Lightweight Fill Material 'Super Sol' Contributes to Shortening Construction Period](https://image.www.ipros.com/public/product/image/34a/2001484168/IPROS17684061539955573659.png?w=280&h=280)

![[Super Sol Construction Case] A2 Tail Arm Fill Material Case [Yamagata]](https://image.www.ipros.com/public/product/image/2da/2000317482/IPROS59567686660623847853.jpeg?w=280&h=280)