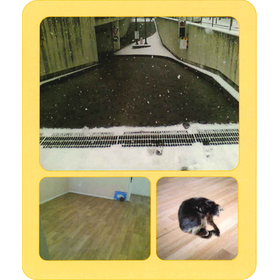

[Disaster Recovery Construction Case] Lightweight Fill Material 'Super Sol' Contributes to Shortening Construction Period

There are construction case studies for disaster recovery work! No curing period is required, allowing for a shortened construction period.

We would like to introduce a case of construction work for disaster recovery using Super Sol conducted by our company. To proceed with the construction quickly, it is essential to ensure timely delivery of materials, transportation to the site, constructability, material costs, and stable supply of materials. "Super Sol" can reduce costs when combined with crushed stone (such as excavated soil). It can be constructed using standard earthwork procedures, contributing to a shortened construction period. We have examples of disaster recovery construction, tsunami evacuation road widening projects, and mixed lightweight soil and sandwich-type construction. Please take a look at our catalog. 【Benefits】 - Shortened construction period (no curing time required) - Proven case studies in disaster recovery construction - Very lightweight with a unit weight of 4 kN/m³, allowing adjustments to 11 kN/m³ when combined with crushed stone, etc. - Can be constructed using standard earthwork procedures, contributing to a shortened construction period - Shipping available from 18 factories nationwide, from Hokkaido to Okinawa *For more details, please download the PDF or feel free to contact us.

Inquire About This Product

basic information

For more details, please download the PDF or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

【Super Soil Applications】 ■ Lightweight fill (soft ground/settlement measures) ■ Backfill for structures (retaining walls/reinforced earth walls/bridge abutments/riverbanks/wharves) ■ Foundations for structures ■ Protection of structures (existing structures/BOX culvert protection/underground installations/underground pipes) ■ Backfilling (underground parking lots) ■ Elevation (railway platforms) ■ Drainage materials (drainage ditches/EPS backfill) *For more details, please download the PDF or feel free to contact us.

catalog(3)

Download All CatalogsCompany information

"Super Sol," made by crushing and sintering waste glass, is a lightweight material with countless holes, forming a porous structure. It is an artificial lightweight stone with an irregular shape and a particle size of 2 to 75 mm. There are products with varying specific gravities and water absorption rates to suit different applications. Composed of soil components, it is an eco-friendly product with an eco-mark. **Features of Super Sol:** - **Lightweight:** It is 1/6 to 1/5 the weight of soil, with a proven track record as a lightweight fill material. By combining it with crushed stone, the unit weight can be controlled between 4 kN/m³ and 11 kN/m³. - **Drainage:** It can be used as a drainage material in civil engineering and greening projects. - **Aeration and Water Retention:** It can be used as an inorganic soil amendment for greening. - **Workability:** Its lightweight nature makes it easy to handle, facilitating construction in uneven terrains and confined spaces. Like crushed stone, it can be installed through leveling and compaction without the need for curing periods or special techniques. - **Stability:** Being mineral-based and inorganic, it is physically and chemically stable, with no corrosion. - **Safety:** As it is made from naturally derived glass, Super Sol is composed of soil components, making it a highly safe material for the surrounding environment.

![[Super Sol Construction Case] Example of Arch Culvert Protection](https://image.www.ipros.com/public/product/image/158/2000252452/IPROS8970663017331780390.jpg?w=280&h=280)

![[Super Sol Construction Case] A2 Case of using L4 for backfill material of the quay wall](https://image.www.ipros.com/public/product/image/408/2000253389/IPROS587673142581969347.jpg?w=280&h=280)

![[Super Soil Construction Case] A2 Tail Arm Fill Material Case [Tochigi]](https://image.www.ipros.com/public/product/image/08c/2000253379/IPROS528273161249700630.jpg?w=280&h=280)

![[Super Sol Construction Case] A2 Case of Road Widening Work on Steep Slopes, Tochigi](https://image.www.ipros.com/public/product/image/af0/2000253380/IPROS5997063772885203728.jpg?w=280&h=280)

![Recycled plastic lightweight flooring sheet Shi Taro! [Alternative to steel plates and rubber mats]](https://image.www.ipros.com/public/product/image/ce2/2000953417/IPROS81400705517907518490.png?w=280&h=280)