Evaluation of thermal degradation rubber by DMA

This paper introduces the evaluation of thermally degraded rubber using dynamic viscoelastic measurements.

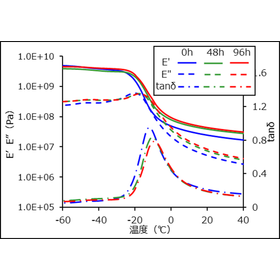

A constant temperature bath capable of circulating air within the chamber was used as a suitable device for thermal degradation testing, and NBR rubber and EPDM rubber were heated at 100°C for a specified duration. The changes in viscoelastic behavior due to heating time were investigated.

For both types of rubber, as the heating time increased, tanδ (=E"/E') showed a peak that shifted to the higher temperature side, and a decrease in peak value was observed. It is believed that the loss of rubber elasticity and the decrease in elastic modulus resulted in the shift of Tg to the higher temperature side.

By measuring dynamic viscoelasticity, it becomes possible to confirm the changes in physical properties associated with material degradation and to gain insights into structural changes. Additionally, conducting other chemical analyses can clarify more specific changes in chemical structure.

Inquiry about this news

Contact Us OnlineMore Details & Registration

Details & Registration