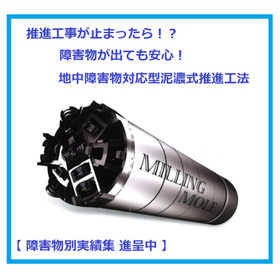

Subsurface Obstacle Adaptable Slurry Shield Tunneling Method *Performance Collection by Obstacle Type Available!

The milling mall method is safe even when obstacles appear! A thrust method chosen nationwide, compatible with diameters from φ800 to 3000 mm. *Registered with NETIS.

The underground obstacle response type mud-based thrusting method "Milling Mole Method," equipped with four special functions: exploration, improvement, cutting, and guidance, consists of three devices: a tunneling machine, a special telescopic pipe, and a special injection pipe, allowing for the fine cutting and discharge of underground obstacles. Using electromagnetic waves, it explores metal obstacles ahead while thrusting and can also improve the ground from within the tunneling machine before and after the detected obstacles. In the event that an obstacle is detected, the special telescopic device can be used to cut through the underground obstacle at ultra-low speed, allowing for continued thrusting. Furthermore, a system is also equipped to guide the tunneling machine to a designated position by installing a receiving coil at the specified location within the arrival shaft, enabling high-precision arrival even in the presence of obstacles. 【Performance by Obstacle Type】 ■CASE-6 Steel Sheet Pile 3W Cutting ■CASE-7 Steel Sheet Pile 3 & H Steel Cutting ■CASE-8 Wooden Pile & Steel Sheet Pile Cutting ■CASE-9 H Steel & Existing Manhole Wall Cutting ■CASE-10 Underground Continuous Wall & Metal Object Cutting *For more details, please refer to the PDF document or feel free to contact us.

- Company:ヤスダエンジニアリング

- Price:Other