It is also possible to manufacture a combined furnace for annealing and hardening.

For 40 years since our establishment, we have manufactured over 1,500 industrial furnaces. With technology capable of meeting AMS standards (U.S. aerospace standards), we have provided custom solutions tailored to our customers' needs. We also propose optimal annealing furnaces, including peripheral areas such as automatic transport. 【Features】 ■ Capable of appropriate cooling control for rapid cooling, slow cooling, and over-aging ■ Capable of achieving precise temperature distribution ■ Able to introduce various atmosphere gases 【Problem Solving】 We have addressed the following challenges: ■ Wanting to prevent heat loss in the furnace during replacement to increase the efficiency of batch furnaces ■ Concerned about whether the cooling of thick materials can meet the specified time ■ Due to high water pressure during processing, there is a possibility of deformation in rectangular cooling zones Please feel free to consult us for small lot production, heat treatment testing, or small sample manufacturing. *For more details, please refer to the PDF document or feel free to contact us.

Inquire About This Product

basic information

【Specifications】 ■Temperature: Up to 1200℃ ■Atmosphere: Air / Nitrogen / Hydrogen / Argon / AX Gas ■Applications: Annealing of metal materials / Internal stress removal / Improvement of material properties ■Main processed items: Stress relief annealing / Bright annealing / Intermediate annealing / Tension annealing / Softening annealing, etc. ■Main transport methods: Batch type / Pit type / Bell type / Cart type / Rotary retort type, etc. *For more details, please refer to the PDF document or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

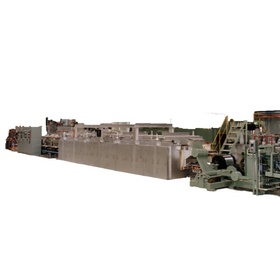

【Applications】 ■ Annealing of metal materials / Internal stress removal / Improvement of material properties 【Product Examples】 ■ Elevator-type annealing furnace / Strand-type bright annealing furnace for wire / Roller hearth-type annealing furnace *For more details, please refer to the PDF document or feel free to contact us.

catalog(3)

Download All CatalogsCompany information

The manufacturing process of industrial products in all fields almost always includes a heating process. Due to the various factors such as the material, size, processing volume, temperature, atmospheric gas, and transportation method of the items being processed, heating devices, or thermal treatment furnaces, will have different specifications. Our company has traditionally responded to user expectations with a flexible design and manufacturing system. We have accumulated extensive experience and achievements across various powdered materials, including metal materials, mechanical parts, electronic components made of glass and ceramics, magnetic materials, and battery materials, regardless of the target objects. In recent years, it has become rare for thermal treatment furnaces to serve merely as heating devices; they are often required to have some additional functions. In addition to safety, energy efficiency, and automation, we actively incorporate advanced technologies to address environmental issues and enhance usability, going beyond merely following past technologies, and we will continue to create together with our customers.