A specialized cleaning agent designed to address glazes that are difficult to remove with standard ink cleaning methods.

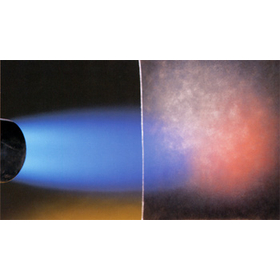

The "Roller Activator" was developed as a specialized treatment agent to address glazes that are difficult to resolve with standard ink cleaning. In small printing machines primarily using paper plates, the components of the dampening solution are unique due to differences in plate structure, and they are used in high-concentration dilutions. As a result, a significant amount of dirt caused by over-emulsification of the ink occurs, and at the same time, many components of the dampening water that lead to insensitivity adhere to the ink rollers. The insensitive components in the dampening water that act on the plate surface work on the surface of the ink rollers to form glazes, leading to the roller stripping phenomenon. Once a glaze forms, it continues to accumulate and adhere in the same area. This is a completely new type of glaze remover that does not contain abrasives. [Features] ■ A completely new type of glaze remover that does not contain abrasives. *For more details, please refer to the PDF document or feel free to contact us.

Inquire About This Product

basic information

【Applicable Laws】 ■PRTR Law: Contains Class I designated chemical substances ■Organic Solvents Regulation: Contains Class III organic solvents ■Fire Service Act: Hazardous materials Class 4, Type 2 petroleum products (non-aqueous liquids) / Hazard class III *For more details, please refer to the PDF document or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the PDF document or feel free to contact us.

catalog(2)

Download All CatalogsCompany information

Nikken Chemical Research Institute Co., Ltd. conducts research and manufacturing sales of printing and plate-making equipment and its related materials. Our company values the connections and dialogue between people and aims to be a company that is always close to our customers.

![[NETIS Registered Product] Single Pipe Barricade 'The Barricade'](https://image.www.ipros.com/public/product/image/2070280/IPROS2490309052512170556.png?w=280&h=280)