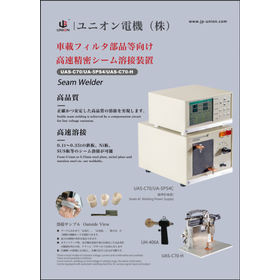

Seam welding machine, resistance brazing machine, spot brazing machine, electric brazing machine.

UAS-C70・UA-5PS4C

Single-phase AC seam welding power supply, resistance soldering machine, electric soldering machine, spot soldering machine, and can also be repurposed as a spot welding machine.

* Seam welding of steel plates, nickel plates, SUS plates, etc., from 0.1t to 0.35t is possible. * Can be used as a spot welding machine. * Equipped with a power supply voltage fluctuation compensation circuit, enabling stable welding. * All conditions are displayed on an LED. * Comes with a memory function. * Voltage adjustment tap included, with 7 levels. * Please consult for sample experiments. * Can be used as a "resistance soldering machine" with a hand mini-gun. * UH-407 spot-specific handgun activates when a certain pressure is reached. Uniform welding can be achieved even with different operators.

Inquire About This Product

basic information

Dimensions: 350 (W) × 300 (D) × 225 (H) Weight: Approximately 30 kg Power Supply: 200V–220V 50/60

Price range

P4

Delivery Time

Applications/Examples of results

Seam welding of steel plates, nickel plates, SUS plates, etc. with a thickness of 0.1t to 0.35t Spot welding of copper Spot welding of brass and copper Spot welding of brass and brass Resistance brazing of aluminum materials and rods Resistance brazing of glass and brass terminals Welding of wire mesh Welding of 500 MESH Welding of φ6 and SUS plates

Detailed information

-

Hand Roller Gun (UH-406A)

-

Hand Mini Gun UHD-401 The electrode used is φ3 tungsten electrode, alumina dispersion reinforced copper UE-ODS3.

-

UH-407 is a handgun designed for spot use. It activates when the electrode is pressed against the work and reaches a certain level of pressure.

-

You can adjust the pressure by turning the knob.

Company information

Union Electric Co., Ltd. is a manufacturer and seller of related equipment for resistance (spot) welding and laser welding. We also produce specialized machines for battery welding (tab welding, can bottom welding) and motor welding (hairpin welding, terminal welding). Please leave the production of automatic machines for mass production to us. □ Tab welding for primary and secondary batteries, motor welding, hairpin welding, fusing welding, seam welding of wire mesh, spot welding, aluminum butt welding, battery tab (welding of metal foil) You can also trust us with the processing of tungsten and molybdenum electrodes. If you have any welding needs for metals, please consult with us. We are also willing to assist with development products and sample testing. Please contact Tanba from our sales department.