The on-site process can be shortened, allowing for rapid construction! There is no need for assembly and disassembly of formwork support structures at sea.

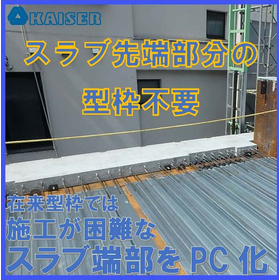

The "Precast PC Structure Pier-type Seismic-resistant Berth (Quay)" is a pier-type quay structure that consists of a lattice beam made of precast components supported by vertically driven steel pipe piles, with PC slabs laid on top and cast-in-place concrete forming a composite deck structure. Due to the use of precast components, there is no need for the assembly and disassembly of formwork and support structures at sea. Additionally, by using materials with a low water-cement ratio and high strength, the concrete becomes dense and exhibits excellent durability. 【Features】 ■ No waste materials from formwork, does not pollute seawater ■ Shortened on-site processes, enabling rapid construction ■ High quality due to reliable management and production in well-equipped locations ■ Excellent resistance to salt damage by using full prestressing ■ Dense concrete resulting in superior durability *For more details, please refer to the PDF document or feel free to contact us.

Inquire About This Product

basic information

【Construction Sequence】 ■Installation of main beams ↓ ■Installation and tensioning of cross beams ↓ ■Installation of receiving beams for crash barriers ↓ ■Laying of PC slabs ↓ ■Pouring of floor slab concrete *For more details, please refer to the PDF document or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the PDF document or feel free to contact us.

catalog(1)

Download All CatalogsCompany information

Our company was established in April 1952, focusing on the uniqueness of prestressed concrete (PC) introduced from France at that time. As a pioneer of PC technology in our country, we have contributed to national land development and the advancement of local communities for over 60 years, primarily through bridge construction. Moving forward, we are committed not only to new construction projects but also to enhancing measures for the longevity of bridges, strengthening maintenance and repair technologies, and developing new technologies and methods, all in efforts to create PC structures that meet societal needs.

![[Construction Example] Archicon Exterior Concrete Components (Landscape/Exterior)](https://image.www.ipros.com/public/product/image/a3e/2000596660/IPROS80781626338388902957.jpeg?w=280&h=280)