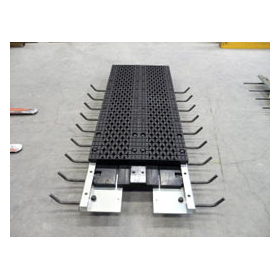

Steel frame revetment responding to environmental and cost reduction.

This construction method involves assembling a lightweight main sheet with joint fittings and bolts to create a framework, filling it with infill material to maintain flood control functionality. The components are lightweight, and assembly and installation are simple tasks that only require bolted connections. Even when installing a top cover, it can be easily connected using super clips, demonstrating excellent workability.

Inquire About This Product

basic information

This is a multi-natural revetment method using lightweight formwork made of high corrosion-resistant steel plates, which fills the frame with backfill materials such as soil and sand. When the backfill material is rock, it can be used instead of basket mats, cobblestone coarse woodwork, or willow branch work; when the backfill is soil, it can be used instead of soil cover blocks. Assembly and installation do not require heavy machinery and can be done manually. For this reason, it is used in the substructures of bridges and in greening works for existing revetments.

Price information

Prices may vary depending on specifications and quantities.

Delivery Time

P4

※The delivery time varies depending on the quantity.

Applications/Examples of results

11 locations by the Ministry of Land, Infrastructure, Transport and Tourism (H-300 to H-200), 4 locations in Miyagi Prefecture (H-300), 2 locations by the Railway Construction and Maintenance Support Organization (H-250), 4 locations in Omuta City (H-300), 1 location in Fukuoka Prefecture (H-300), 2 locations in Kanagawa Prefecture (H-300).

Detailed information

-

Type of Cap Wood Installation The cap wood logs are selected based on the surrounding landscape and environment. Additionally, if the infill material is stone and there is no upper cover mesh, it is advisable to use cap wood logs to prevent stones from protruding. The logs used should be thinned wood with a diameter of approximately 75 to 100 mm, fixed to the main sheet with special fittings.

Line up(3)

| Model number | overview |

|---|---|

| H-200 | Dimensions: 0.2×(1.0–1.5)×2.0m Slope gradient: θ≧1:2.0 Flow velocity: v≦4.0m/s Filling material particle size: 5–15cm Applicable construction type: Revetted embankment covering |

| H-300 | Dimensions: 0.3×(1.0–1.5)×2.0m Slope gradient: θ≧1:2.0 Flow velocity: v≦5.0m/s Filling material particle size: 5–15cm Applicable construction type: Revetted embankment covering |

| H-450 | Dimensions: 0.45×(1.0–1.5)×2.0m Slope gradient: θ≧1:2.0 Flow velocity: v≦5.0m/s Filling material particle size: 15–20cm Applicable construction type: Revetted embankment covering and bed protection |

Company information

Tohō Giken Co., Ltd. was established in July 1979 with the corporate philosophy of "Advanced Technology and Creativity," operating as a knowledge-intensive company. The main focus of the company's business is the development and dissemination of new methods and products for riverbank protection. We have developed numerous unique riverbank protection methods and products that are rare in the industry, accumulating a track record of construction and receiving recognition as innovative methods and products. In particular, in recent years, we have been promoting the "Multi-Natural River Creation" method, striving to develop new methods and materials that reduce labor and resources while also considering and improving environmental impacts, based on traditional river construction methods in our country. We are also promoting our business through active applications for industrial property rights and registration with NETIS, aiming for business expansion through licensing agreements with companies in various regions and partnerships with different industries. Recently, we have been developing and selling products aimed at individuals that consider the global environment, in addition to civil engineering construction materials.

![[Construction Example] Greening of a hill created at the port with consideration for the landscape.](https://image.www.ipros.com/public/product/image/875/2001513099/IPROS10845765744929396590.png?w=280&h=280)