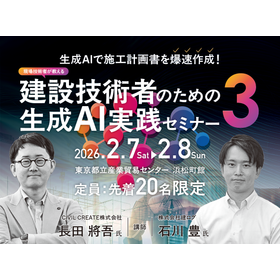

[Exhibition Information] Formnext Forum Tokyo 2023 (September)

We will be exhibiting at the Formnext Forum Tokyo again this year!

Formnext Forum Tokyo, a sister event of the international specialized trade fair Formnext held annually in Frankfurt, focuses on AM (Additive Manufacturing) technology and industrial 3D printing. It is a combined event featuring exhibitions and seminars where AM technologies, related technologies, products, services, and information, including 3D printing, come together. We look forward to your visit.

Date and Time: September 28 (Thursday) – 29 (Friday), 2023, 10:00 AM - 5:00 PM

Venue: Tokyo Metropolitan Industrial Trade Center, Hamamatsucho

Booth Number: 4F C006

| Date and time | Thursday, Sep 28, 2023 ~ Friday, Sep 29, 2023 10:00 AM ~ 05:00 PM Booth number: 4F C006 |

|---|---|

| Capital | Tokyo Metropolitan Industrial Trade Center Hamamatsucho Building [Address] 〒105-7501 1-7-1 Kaigan, Minato-ku, Tokyo, Tokyo Port City Takeshiba |

| Entry fee | Free We will provide you with a free invitation ticket. |

Inquiry about this news

Contact Us OnlineMore Details & Registration

Details & Registration

![[Explanation] Laser Powder Bed Fusion (LPBF) Metal 3D Printer / Aconity3D Corporation](https://image.www.ipros.com/public/catalog/image/01/bd0/697601/IPROS39376307182525717193.png?w=120&h=170)

![[Explanation] Electron Beam Powder Bed Fusion (EB-PBF) Metal 3D Printer / Wayland Additive Company](https://image.www.ipros.com/public/catalog/image/01/9c9/682330/IPROS26470025606113033565.png?w=120&h=170)

![[Explanation] Directed Energy Deposition (DED) / RPM Innovations Inc.](https://image.www.ipros.com/public/catalog/image/01/aee/682328/IPROS74590991445054205912.png?w=120&h=170)