1~28 item / All 28 items

Displayed results

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us OnlineBefore making an inquiry

Download PDF1~28 item / All 28 items

"AINECTⓇ" is a WMS software (Warehouse Management System) that enables the efficiency of picking operations in logistics and manufacturing sites, visualization of inventory, and understanding of productivity. It approaches on-site challenges from both hardware and software perspectives, building a resilient foundation against changes. 【Features】 ■ Seamless Integration: Achieves seamless integration with Aioi products, significantly improving operational efficiency on-site. ■ Flexible Scaling: Can flexibly expand specifications even during peak logistics periods. After the busy season, it can revert to the previous contract. ■ Ease of Information Sharing: By simply switching locations upon login, you can check real-time information such as inventory and shipping status. ■ Reduction of Initial Costs: Eliminates the need to arrange installation servers, significantly reducing initial costs. This makes it easier to implement in medium-sized logistics facilities. ■ High Redundancy: Distributes data across multiple data centers, enabling rapid data recovery even in the event of a failure. ■ Excellent Security: Ensures safety through detailed access permission settings, detection and blocking of unauthorized access, and application of the latest security patches.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is the ideal package software for transitioning from paper (list) picking to digital picking. It supports picking tasks not only in factories, such as picking for parts supply and assembly in a cell production system, but also in all environments where people handle goods, such as warehouses and logistics centers. ■ Searching for items while comparing the work list and the shelves in the field alone ■ Needing two people to work together, one to read the list and the other to perform the tasks, to increase efficiency ■ Wanting to implement a digital picking system but having limited time for the implementation This software addresses the challenges faced in such environments.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The latest SmartTag, specialized for transfer time, has arrived. It enables high-speed rewriting of text. 〈What is SmartCard/SmartTag〉 It is an ID card that uses electronic paper. By implementing a display screen with electronic paper, it has achieved visualization. It can freely display text, photos, shapes, barcodes, QR codes, and more, boasting high visibility even under sunlight or in dark warehouses due to its high contrast. It can be utilized in various scenarios such as logistics container labels, manufacturing instructions, ID cards, or as an alternative for work history management, access control, and visitor badges.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

**[Problems Faced by Bookstore B]** Out of approximately 1,600 items, picking was done manually while referring to paper order forms categorized by shipping destination, leading to frequent picking errors and packaging omissions. Additionally, as the labor shortage became more severe, the situation of increasing the number of workers continued, necessitating the establishment of a system for in-house operations that could ensure a certain level of productivity regardless of the worker. **[Implementation Effects]** The efficiency of the picking operation improved productivity by about 1.5 to 2.0 times. The working time was reduced from approximately 8 hours to about 5 hours. Furthermore, the time spent on rework due to picking errors was significantly reduced, contributing to the suppression of logistics costs (including labor costs). **[Product in this Case]** ■ Digital Picking System MWU Series "MWU2040PR" *For more details, please refer to the PDF materials or feel free to contact us.* **[LIVE Showroom Held]** We are conducting a "LIVE Showroom" utilizing the web for easy access. If you are interested, please check the link below.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "3D Projection Picking System (3D PPS)" processes in 3D compared to 2D, allowing for higher precision analysis and finer adjustments. Since it can measure depth, it can automatically measure the distance to the target object. There are no complex settings, and maintenance is easy. 【Features】 ■ The 3D sensor has a simple structure that only requires installation at one location on the top. ■ Initial setup and maintenance are easy. ■ Demonstrates high flexibility. - By processing in 3D, it allows for higher precision analysis and finer adjustments. - Can be used regardless of shelves or flat surfaces, and can also be set up to prevent errors at inclined input locations. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

**[Problems Faced by Company A, a Housing Equipment System Manufacturer]** There was a need to shorten the lead time for deliveries, which required reducing the picking process. Additionally, there was a high turnover of workers, making it urgent to create an environment where anyone could easily perform picking tasks. **[Implementation Effects]** Even workers with low skill levels could perform quick and accurate tasks with just simple operational instructions, significantly reducing the training burden on site supervisors. It became possible to visualize when, who, and what kind of picking tasks were carried out through the terminal's work records, allowing for easy tracing of on-site work performance in the event of any defects. **[Products in this Case]** ■ AW Series "AW2009FM" ■ AW Series "AW2038FM" *For more details, please refer to the PDF document or feel free to contact us.* **[LIVE Showroom Now Open]** We are conducting a "LIVE Showroom" utilizing the web for easy access. If you are interested, please check the link below.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

**[Problems faced by Manufacturer C]** Due to issues such as delays and mistakes in picking, and the time required for training in picking operations, they were searching for a system to prevent misassembly and shortages of critical safety components that are related to human life. **[Implementation Effects]** This led to a reduction in lost man-hours due to work delays and incorrect shipments, a decrease in training time, and measures to prevent misassembly and shortages of functional components related to human life in automotive parts. With the digital picking system, anyone can perform picking tasks without making mistakes, resulting in reduced work delays and picking errors. Additionally, by displaying caution information through photos and text, the incidence of mistakes in delivery locations has significantly decreased. **[Products in this Case]** ■ SW Series ■ Projection Picking System PPS *For more details, please refer to the PDF materials or feel free to contact us.* **[LIVE Showroom Now Open]** We are conducting a "LIVE Showroom" utilizing the web for easy access. If you are interested, please check the link below.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

**[Problems faced by Medical Device Manufacturer E]** In the outbound operations, there was a need to establish a smart system that anyone could operate and to implement a system that would lead to a reduction in the number of workers. **[Implementation Effects]** By conducting logistics analysis on the hit rate of products and dividing the storage areas for products A, B, and C, the walking routes were shortened by using conveyors, resulting in a 17% increase in work efficiency compared to before. Due to the simple system where tasks are performed according to the instructions on the display, consideration was given to the workers, and an easy-to-use sorting system was realized, successfully reducing the number of workers. **[Products in this Case]** - MWU Series "MWU2040PF" - JW Series "JW2050F-23" - JW Series "JW2000LF" - 14-Segment Batch Display "MWU2414" *For more details, please refer to the PDF materials or feel free to contact us.* **[LIVE Showroom Currently Held]** We are conducting a "LIVE Showroom" utilizing the web for easy access. If you are interested, please check the link below.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

**[Problems faced by Apparel Company A]** It was necessary for workers to decide on the set of shipping boxes of various sizes, and they wanted to automatically transport the required types and quantities of boxes to a single shipping destination. Additionally, there was a challenge in adjusting the number of workers according to the volume of goods when picking in order of store number. **[Implementation Effects]** By instructing workers based on the results of capacity calculations, smooth supply of shipping boxes became possible. This allowed for the automatic transportation of multiple boxes needed for a single shipping destination, eliminating the need for repacking or additional label issuance due to later changes in boxes. Furthermore, by processing stores with a high volume of goods in the first half and then switching to store number order, it became possible to reduce the number of workers in the latter half. **[Product in this case]** ■ JW Series "JW2030R" *For more details, please refer to the PDF document or feel free to contact us.* **[LIVE Showroom Currently Held]** We are conducting a "LIVE Showroom" utilizing the web for easy access. If you are interested, please check the link below.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

**[Problems Faced by Comprehensive Logistics Company A]** It has been decided that the volume of goods will approximately double, but due to difficulties in hiring, it has become challenging to increase the workforce, and the current list picking method is no longer sufficient. Additionally, due to changes in contract terms with clients, there are challenges such as the need for quick collection of goods on the same day they arrive. **[Implementation Effects]** By utilizing the flexibility of wireless displays and creatively arranging the warehouse layout, we were able to complete tasks that were initially planned for multiple batches in just one batch, resulting in increased efficiency. As a result of improved collection efficiency, we achieved a response to the increased volume without increasing the workforce and shortened lead times. **[Product for This Case]** ■ NW Series "NW2978-01" *For more details, please refer to the PDF document or feel free to contact us.* **[LIVE Showroom Currently Held]** We are conducting a "LIVE Showroom" utilizing the web for convenience. If you are interested, please check the link below.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

**[Problems Faced by Apparel Company B]** Two personnel were always required for the sorting process: one to read the SKU sorting list and another to perform the sorting tasks. Due to the large number of similar products, it was difficult to distinguish between them, leading to sorting errors. Additionally, the sorting method needed to change based on the volume of items, requiring a system that could adapt to these changes. **[Implementation Effects]** Traditionally, the sorting process required two personnel: a reader and a worker. Now, by simply scanning store and SKU labels, it has become possible to visually determine the sorting destination, picking items, and quantities, eliminating the need for a reader. Utilizing the system capabilities of the packaged software, we switched to DPS/DAS according to item volume, customers, and the number of workers, enabling operations that are resilient to changes. The construction costs were also reduced as the logistics center employees carried out the installation. **[Products in This Case]** ■ MWU Series "MWU2040PF" ■ Parts Master 3 *For more details, please refer to the PDF document or feel free to contact us.* **[LIVE Showroom Now Open]** We are conducting a "LIVE Showroom" utilizing the web for easy access. If you are interested, please check the link below.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

**[Problems Faced by the Comprehensive Food Logistics Company]** It was difficult to increase the number of workers, and we aimed to improve productivity per person and reduce shipping errors. Considering the complaints due to incorrect shipments and the time spent addressing them, we wanted to prevent mistakes in loading items into the entrance. Additionally, we faced the challenge of not separating crates and milk boxes on racks, wanting to handle both on the same rack and use them in any preferred location within the warehouse depending on the volume and timing. We also wanted to store racks in a different location when not in use. **[Implementation Effects]** Mistakes in loading items incorrectly have drastically decreased. Since LED tapes are installed in different colors for each section, we can avoid loading errors and move racks, allowing for effective utilization of space within the warehouse. **[Products in this Case]** - JW Series "JW2050F" - LED Tape - Signal Light Interface "TW2911" *For more details, please refer to the PDF document or feel free to contact us.* **[LIVE Showroom Currently Available]** We are conducting a "LIVE Showroom" utilizing the web for convenience. If you are interested, please check the link below.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

【Problems Faced by Company A in the Mail Order Business】 As securing workers has become increasingly difficult year by year, they are looking to establish a system that is effective for labor-saving. Until now, they have been sorting using a simple DAS, but they have faced challenges in improving work productivity and sorting accuracy. 【Implementation Effects】 By combining DPS with a piece sorter, it has become possible to sort flyers with the piece sorter, significantly improving sorting accuracy compared to manual labor. Sorting is simple; after scanning the products, they are just placed on the conveyor belt, allowing anyone to sort immediately with minimal training. 【Products in This Case】 ■ SW Series "SW1001F" ■ JW Series "JW2030R" ■ JW Series "JW2030G" ■ JW Series "JW2030B" *For more details, please refer to the PDF materials or feel free to contact us. 【LIVE Showroom Currently Open】 We are conducting a "LIVE Showroom" utilizing the web for convenience. If you are interested, please check the link below.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce the operational case of the Projection Picking System (PPS). The "Cell Production Solution" is a system that utilizes PPS to support cell production. With projection from a projector, it can display a variety of information such as images and text. The picking area for parts is projected visually, and a poka-yoke function provides warnings for mistakes. It can also be linked to the tightening signal of a torque wrench. 【Features】 ■ Displays work procedures using a projector to guide assembly tasks ■ By establishing standard operations, anyone can produce products with consistent quality ■ Helps reduce training time for workers ■ Can also link to the completion signal of the torque wrench ■ If the number of tightenings is incorrect, the poka-yoke function will cause the shelf to light up red and a buzzer to sound *For more details, please refer to the PDF document or feel free to contact us. 【LIVE Showroom Now Open】 We are conducting a "LIVE Showroom" utilizing the web for easy access. If you are interested, please check the link below.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

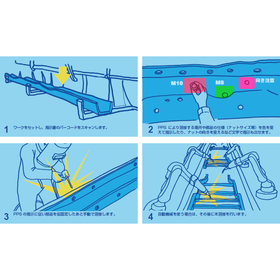

We would like to introduce the operational case of the Projection Picking System (PPS). The "AGV-linked Sorting Solution" allows AGVs to automatically travel within the warehouse and deliver products to the picking stations. Picking is performed according to the content projected by the PPS on the delivered shelves, and in addition to the front display, it can clearly show the quantity, product information, and more to the operators. The PPS is equipped with a mistake-proofing function, which improves picking accuracy. 【Features】 ■ Shelves are transported by lift-up AGVs ■ Sorting tasks are supported by projections from a projector ■ Since AGVs handle automatic transportation, the physical effort of walking for operators is reduced ■ There is no need to memorize product shelves ■ Inbound operations are also performed by scanning the product barcodes and following the instructions from the PPS *For more details, please refer to the PDF materials or feel free to contact us. 【LIVE Showroom Now Open】 We are conducting a "LIVE Showroom" utilizing the web for easy access. If you are interested, please check the link below.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a use case for the Projection Picking System (PPS). The "Welding Position Projection Solution" projects the welding positions of sheet metal, such as vehicle chassis, using PPS. By following these instructions to weld nuts and components, there is no longer a need to create processing jigs (gabarit). Since the projection can also display information such as text and shapes, it contributes to error-proofing and work improvement, reducing the costs and associated efforts of creating processing jigs (gabarit) for frequent specification changes and new models, as well as storage and picking. 【Features】 ■ Indicates the welding positions of parts during sheet metal processing using a projector ■ Projects the welding positions of sheet metal, such as vehicle chassis, using PPS ■ Eliminates the need to create processing jigs (gabarit) ■ Can display information such as text and shapes through projection ■ Contributes to error-proofing and work improvement *For more details, please refer to the PDF document or feel free to contact us. 【LIVE Showroom Now Open】 We are conducting a "LIVE Showroom" utilizing the web for easy access. If you are interested, please check the link below.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The system can project information onto the floor as well as onto the walls, such as sorting work progress information, allowing managers and workers to receive the information they need. It can be utilized not only for "picking operations" but also for sorting operations known as "assorting work." Thanks to projection mapping technology, it does not require equipment installation and has received high praise for its hygiene aspects. Additionally, it can be used in refrigerated warehouses and comes with a wireless switch that does not require batteries, making it easy to communicate work completion information to higher-level systems. ◆ Used by over 1,500 customers 【LIVE showroom currently being held】 We are conducting a "LIVE showroom" utilizing the web for convenience. If you are interested, please check the link below. 【Features】 ■ High visibility with work guidance instructions through projection mapping ■ Projection information can be freely customized to fit the site ■ Easy installation, no wiring required ■ Enables the creation of a hygienic space environment ■ Proven track record in various logistics sites * For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"AI-NET" is a wiring-efficient network system that can transmit power and data using two non-polarized wires. This highly reliable product contributes to improving accuracy and efficiency in manufacturing and logistics worldwide as a foundational technology for digital picking systems and more. Aioi System supports global manufacturing and logistics with two non-polarized wires. 【Features】 ■ Capable of transmitting power and data using two non-polarized wires ■ Highly reliable ■ Contributes to improving accuracy and efficiency in manufacturing and logistics worldwide 【LIVE Showroom Now Open】 We are conducting a "LIVE Showroom" utilizing the web for your convenience. If you are interested, please check the link below. *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The AiOi-made picking system has been implemented in over 70 countries worldwide. We will propose solutions tailored to your challenges, aiming for labor reduction and productivity improvement by utilizing logistics systems. - "Efficiency in picking and sorting operations" - "Prevention of mistakes" - "Visualization of inventory" - "Effective use of space" At AiOi Systems, we have a permanent exhibition that realizes efficiency and visibility throughout logistics centers and factories through a digital integration system. We started an initiative in May to connect our showroom online, allowing for a LIVE experience, and currently, over 1,500 customers from both domestic and overseas have participated. ◆ Solutions that can be introduced in the LIVE showroom (partial list) (1) Various digital picking displays (2) A sorting system with shutters aiming for zero picking and sorting errors (SAS) (3) The latest picking support through video projection. Picking and sorting solutions linked with AGV (4) Battery-less RFID card with electronic paper "Smart Card" (5) Wireless bulk rewriting electronic shelf label solution We will provide proposals while showcasing case studies.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The Aioi System's digital picking system has been implemented in over 5,000 systems across various logistics centers to improve logistics work efficiency. It has been adopted in 72 countries worldwide, with over 5 million units sold. With a wealth of implementation experience unique to the industry leader, we offer a variety of display types and tailor our proposals to fit each customer's site. 【Features】 ● Flexible wiring with two non-polar lines ● Easy to expand and relocate ● Available in compact sizes and sensor-linked types ● Short lead time startup possible with packaged software ● Capability to retain work history as data ● Aioi's displays are environmentally friendly products that use green materials (materials that do not contain specified harmful substances) for purchased products, parts, and materials. 【LIVE Showroom Now Open】 We are conducting a "LIVE Showroom" utilizing the web for easy access. If you are interested, please check the link below. *For more details, please download the catalog or check the introduction video below.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The Aioi System's digital picking system has been implemented in over 5,000 systems at various logistics centers to improve logistics work efficiency. It has been introduced in 73 countries worldwide, with over 5 million units sold. With a wealth of implementation experience and a variety of display types available, we offer tailored proposals for each customer's site. ● Flexible wiring with two non-polar lines ● Easy to expand and relocate ● Available in compact sizes and sensor-linked types ● Quick setup possible with packaged software ● Ability to retain work history as data ● Aioi's displays are environmentally friendly products that use green materials (materials that do not contain specified harmful substances) for purchased goods, parts, and materials. 【LIVE Showroom Now Open】 We are conducting a "LIVE Showroom" utilizing the web for easy access. If you are interested, please check the link below. *For more details, please download the catalog or check the introduction video below.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At AiOi System, we have a permanent exhibition that realizes efficiency and visualization throughout logistics centers and factories through a digital integration system. (5 minutes walk from the North Exit of Omori Station on the JR Keihin-Tohoku Line) In addition to the digital picking system, we offer demonstrations of work visualization through the use of smart cards in conjunction with smartphones, as well as the latest picking system, the "Projection Picking System." We will propose various systems while you can see real examples. Please feel free to visit us with a reservation. 【Tokyo Showroom】 ■ Tokyo Headquarters, 5 minutes walk from JR Omori Station ■ Opening Hours: 10:00 AM - 4:00 PM ■ Closed: Saturdays, Sundays, public holidays / year-end and New Year / summer vacation ■ Reservation: By appointment only * There is no dedicated parking available ■ TEL: 03-3764-0228 * For more details, please feel free to contact us. 【LIVE Showroom Currently Open】 We are conducting a "LIVE Showroom" utilizing the web for easy access. If you are interested, please check the link below.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Projection Picking System (PPS)" is a picking system that uses a projector to display necessary information directly onto the shelves. 【Features】 ■ No wiring required ■ Display text supports multiple languages. Font and display colors can also be changed ■ Voice guidance can be set up as needed ■ Videos for assembly instructions and assembly samples can also be displayed In the LIVE showroom, we introduce solutions using AGVs and picking stations to maximize efficiency in small-lot and high-frequency picking operations. 【LIVE Showroom Now Open】 We are conducting a "LIVE Showroom" utilizing the web for easy access. If you are interested, please check the link below.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The SAS (Shutter Assort System) utilizes the latest type of shutter-equipped display to minimize sorting errors to nearly "zero," making it a small-lot sorting system that can accommodate both seeding and harvesting. It achieves improved accuracy, enhanced efficiency, reduced training costs, and quantification of processes. It is a digital picking system that notifies the location of picking instructions with lamps and shutters. <Product Features> ★ Dramatically reduces mistakes with shutters Compatible with both seeding and harvesting. ★ Detailed settings available to suit various applications Settings for angle, speed, and cutoff time are possible. Easy adjustments can be made according to the work content. ★ User-friendly design with a wide button area The wide push-button area makes operation simple. The three-digit display uses easily visible LEDs. ★ Easy installation with minimal wiring No connectors are needed, making installation and maintenance simple. Various base options for ducts, flat surfaces, and pipes are available. ★ Equipped with the latest features for various settings via smartphones or HHT NFC communication allows for address settings and various configurations such as angles. ★ Safety-conscious design The release function activates even if the operator collides, ensuring safety. *For more details, please feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "JW Series" is a long-selling product with a wide variety of options. The duct can be easily separated into two conductor rails and a plastic duct, allowing for resource recycling. It uses materials that do not emit harmful gases during incineration. The clean and fresh milky white color makes it suitable for use in any setting. 【Features】 ■ A reliable and extensive lineup ■ The installation duct consists of two conductor rails and a plastic duct ■ Easily separable for resource recycling ■ The plastic duct is made from materials that do not emit toxic gases during incineration *For more details, please refer to the PDF document or feel free to contact us. ★ The "LIVE Showroom" is currently being held with great success! ↓ Here is a 1-minute introduction video ↓ https://youtu.be/hPjTeW4YoWk

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "SW Series" is a compact type of light module suitable for small items. It can be easily installed by simply adhering a dedicated duct to existing pipe racks or flat shelves. With high visibility, it supports error-free picking operations even for small openings such as small items. Additionally, the mounting duct consists of two conductor rails and a plastic duct. It can be easily separated for resource recycling. 【Features】 ■ Compact type suitable for small items ■ The plastic duct is made from materials that do not emit toxic gases when incinerated ■ Can be installed on both flat shelves and pipe racks *For more details, please refer to the PDF document or feel free to contact us. ★ The "LIVE Showroom" is currently being held with great success! ↓ Here is a 1-minute introduction video ↓ https://youtu.be/hPjTeW4YoWk

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

It displays the number of items shown on the display, allowing for accurate sorting of the correct quantity, which thoroughly prevents mistakes. During the sorting stage by delivery destination, inspection work based on weight is also conducted simultaneously, thoroughly preventing sorting errors. The sorting position and quantity are confirmed with the display's lamps, and the system automatically determines any excess or shortage in quantity. If there is an error, it alerts with a light, helping anyone sort without mistakes. ★ 'LIVE Showroom' is currently being held with great success! ↓ Here is a 1-minute introduction video ↓ https://youtu.be/hPjTeW4YoWk

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is a picking system that does not rely on human experience, intuition, or memory, and is linked to work instructions. Even beginners, not just veterans, can reduce mistakes and perform tasks. ● Human Sensor The human sensor allows the switch to be activated automatically when someone stands in front of it. ● Worker Management Workers can be registered and managed using a card reader. ● Tool Usage Indication Tools to be used are displayed with lamps for each tool. ● Lamp Display Simply pick from the area where the lamp is lit. ★ 'LIVE Showroom' is currently being held with great success! ↓ Here is a 1-minute introduction video ↓ https://youtu.be/hPjTeW4YoWk 【LIVE Showroom in Progress】 We are conducting a "LIVE Showroom" utilizing the web for convenience. If you are interested, please check the link below.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration