1~28 item / All 28 items

Displayed results

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us Online1~28 item / All 28 items

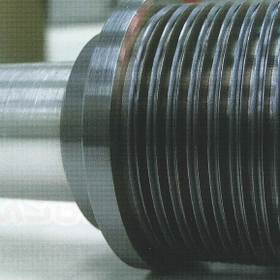

We would like to introduce examples of processing and machining of our "4-wheel transmission components." We handle machining of bearing races, ring gears, suspension cylinders, CVJs, synchronizers, bearings, hubs, and sleeves. We improve wear resistance, initial break-in characteristics, fatigue strength, and oil film retention. Our company has received numerous requests from many customers and boasts a wealth of achievements. [Examples of Processing and Machining of 4-Wheel Transmission Components (Excerpt)] ■ Input Shaft ■ Ring & Pinion Gears ■ Clutch Release Guide ■ Bearing Race ■ Ring Gear *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce examples of processing and machining for our "4-wheel engine parts." We process parts such as the Nissan L series, Nissan SR series, Ferrari Testarossa, piston pins, eccentric shafts, and exhaust manifolds. We improve wear resistance, initial break-in characteristics, fatigue strength, and oil film retention. Our company has received numerous requests from many customers and boasts a wealth of achievements. [Examples of Processing and Machining for 4-Wheel Engine Parts (Excerpt)] ■ Pistons ■ Rocker Arms & Shafts ■ Crankshafts ■ Cylinders ■ Nissan L series *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce examples of processing and machining of our "motorcycle transmission parts." We have improved wear resistance, initial break-in characteristics, fatigue strength, and oil film retention. Our company has received numerous requests from many customers and boasts a wealth of achievements. Additionally, we have experience with input and output shafts, shift drums, shift forks, and a complete set of Kawasaki transmission parts. [Examples of Processing and Machining of Motorcycle Transmission Parts (Excerpt)] ■ Caliper piston ■ Shift drum ■ Gear ■ Rear suspension rod ■ Input and output shafts *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce examples of processing and machining for our "motorcycle engine parts." We have processed parts such as throttle valves, rocker arms, Kawasaki KH250, Kawasaki Z series, Harley-Davidson, and Kawasaki ZZR1100D. Additionally, we also have achievements in camshafts, valve springs & retainers, cam caps, oil pumps, and cams (DLC on the journal area). [Examples of Processing and Machining for Motorcycle Engine Parts (Excerpt)] ■ Throttle Valve ■ Rocker Arm ■ Kawasaki KH250 ■ Kawasaki Z Series ■ Harley-Davidson *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce the "WPC processing case study of M6 taps" that we conducted. Before WPC processing, the edges were sharp, and there were burrs present, with strong tool marks. After WPC processing, the burrs were removed, and a uniform oil reservoir was formed, resulting in a surface with a consistent pearlescent finish, and the tool marks became less pronounced. 【Case Overview】 ■Before WPC processing - The surface in new condition shows chipping and burrs. ■After WPC processing - The machining marks have become faint, and a uniform dimpled surface has been formed. - Burrs have been eliminated, allowing for stable edge breaking. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce examples of our company's processing and machining of "molds." We process forging molds, shaped punches, punches, mandrels (WPC), rolling dies, dies, punches (wire cut products), and resin extrusion molds. Additionally, we have achievements in SKD11 press punches, SKH51 press punches, SKH51 CVD coated punches, and carbide press dies. 【Examples of Mold Processing and Machining (Excerpt)】 ■ Core pins for resin molding ■ Shaped punches ■ Molding molds (rubber) ■ Forging molds (cores) ■ Punches *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce examples of processing and machining of our "machine parts." We process springs (WPC), shafts for drive simulators (WPC), parts feeders (WPC), and guides (WPC). Additionally, we have achievements in SCM shafts, SCM gears, SCM torsion bars, SUJ needle rollers, and SK pump parts. [Examples of Processing and Machining of Machine Parts (Excerpt)] ■ Screw coil springs ■ Parts feeders (DLC) ■ Shanks (WPC) ■ Springs (WPC) ■ Shafts for drive simulators (WPC) *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce examples of processing and manufacturing of our "beauty and medical devices." Titanium (64 titanium), which is lightweight, hard, and has no impact on the human body, is a material widely used in the medical field. By applying WPC treatment to this 64 titanium, there are various benefits such as improved surface hardness (approximately 1.7 times) and increased fatigue strength. Currently, we are also conducting mass production for surgical instruments used in endoscopic surgery for Company O. 【Examples of customer inquiries】 - We are transporting tablets and powdered medicines, but they get stuck along the way, causing problems. - We want to improve the release properties of molds for tablet formation. - We want to stop using fluorine-based resins for filling nozzles and film guides. - We want to suppress adhesion of medical films for tablets and powdered medicines. - We have issues with transporting powdered medicines and want to address the problem of clumping (falling in clumps). - Powdered medicine often bridges in the hopper, causing blockages. - We want to improve the sliding of transport lines for tablet sheets and powdered medicine packages. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This document is a research paper on the extension of rolling fatigue life due to DLC coating. The experimental methods are explained in sections including sample preparation, evaluation of film properties, fatigue testing, and evaluation of fatigue test samples, along with the experimental results, discussions, and conclusions. Currently, in the automotive parts sector, lightweight design and friction reduction aimed at improving fuel efficiency are urgent challenges, and the power transmission systems, including gears for transmissions, are also being targeted for miniaturization, weight reduction, and low friction. [Contents] ■ Introduction ■ Experimental Methods ■ Experimental Results ■ Discussion ■ Conclusion *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"WPC processing" stands for Wide Peening Cleaning and is a type of shot peening (impact method). It doubles the passability by improving slip properties, reduces clogging, and minimizes material loss. It suppresses adhesion and allows for easy cleaning with air. It forms uneven surfaces and reduces contact area. In other words, since it is not a coating, you can use it with confidence. 【Benefits】 ■ Increases productivity ■ Improves yield ■ Reduces cleaning time ■ Cuts labor and utility costs ■ Measures against foreign matter contamination *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"WPC processing" is a type of cold working that involves high-speed collisions of fine particles (media) measuring several tens of micrometers against the surface of metals, forming countless tiny dimples while simultaneously strengthening only the surface layer. This process enhances fatigue strength by introducing compressive residual stress and refining the crystal grains. As a result, it is increasingly being used as a surface modification technology to improve strength and functionality in various metal products such as machine parts, cutting tools, and molds. [Added Surface Functions] ■ Lubricity ■ Release properties ■ Fluid control ■ Durability ■ Optical properties *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce the entire process of our DLC coating. First, we modify the substrate and perform thorough cleaning, carefully masking the unnecessary parts of the DLC film. After completely wiping down the waiting area in the chamber, we inject acetylene gas. Various gases are injected while applying high voltage. The film is built up by repeating the processes of film formation and cooling, taking about 6 hours to complete. 【Process】 1. Inspection and cleaning 2. Masking 3. DLC coating 4. Finishing *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This document discusses the effects of surface treatment on the tribological properties of DLC (Diamond-Like Carbon). Focusing on fine particle bombardment (FPB), it introduces how surface modification of practical substrates affects the friction characteristics and adhesion of DLC-coated materials. Surface treatment (modification) is an expanding field, and it is believed that various composite treatments, not limited to WPC treatment and DLC composite treatment, will become increasingly important. [Contents] ■ Introduction ■ About fine particle bombardment ■ Composite treatment of fine particle bombardment and DLC coating ■ Conclusion (Future challenges and prospects) *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This document reports on the sliding characteristics of automotive engine sliding bearings with low friction properties. It includes the concept of low friction bearings, bearing structure, wettability with lubricants, non-adhesiveness, as well as the starting friction coefficient from bearing performance tests and seizure tests. Engine bearings are required to respond to high surface pressure due to miniaturization and width reduction, low friction, and lead-free requirements, with an increasing demand for higher bearing performance. 【Contents】 ■ Overview ■ Introduction ■ Low Friction Bearings ■ Bearing Performance Tests ■ Conclusion *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"DLC coating" is a technology that involves coating a nanometer-thin film, primarily composed of carbon and hydrogen, onto metal surfaces. It is an advanced surface treatment technology that achieves high effectiveness in low friction, high durability, high hardness, and corrosion resistance. Our company has successfully developed a technology that combines DLC coating with WPC treatment. By combining these, we can enhance adhesion and further prolong the effects over time. 【Features】 ■ Suppression of oil temperature rise ■ Improvement of transmission lifespan ■ Enhanced piston sliding properties ■ Reduction of mechanical noise ■ Improved engine feel *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce the metal surface treatment by Fujii WPC Co., Ltd. Our technology, including WPC treatment, refines the microstructure of metal surfaces to enhance fatigue strength, friction and wear characteristics, and resistance to seizure. This technology is applied to all 86 RACER’S vehicles. WPC technology is essential for those who engage in hard sports driving on circuits. We take pride in being a company that attracts attention in the field of surface treatment technology research, spanning from industrial to medical and food sectors through motorsports. 【Technology】 ■ WPC Treatment ■ Hyper Moly Shot ■ WPC Treatment + Hyper Moly Shot ■ DLC Coating ■ Tin Shot *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This document introduces the advantages of ultra-short pulse laser processing, including application examples. It covers the mechanisms for reducing friction and wear through surface texture formation with ultra-short pulse lasers, as well as improvements in tribological characteristics through laser processing, 3D wrapping, and DLC composite treatments. Our company and our group company, Friction Co., Ltd., have introduced a picosecond laser system as a new technology to improve tribological characteristics. [Contents] ■ Mechanisms for reducing friction and wear through surface texture formation with ultra-short pulse lasers ■ Improvement of tribological characteristics through laser processing, 3D wrapping, and DLC composite treatments ■ Reduction of friction in valve lifters using ultra-short pulse lasers and 3D wrapping ■ Reduction of friction in piston rings using ultra-short pulse lasers ■ Reduction of friction in turbocharger bearings using ultra-short pulse lasers *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"WPC processing" is a type of cold working that involves colliding fine particles (media) at high speed against the surface of a metal to form countless tiny dimples while simultaneously strengthening only the surface layer. The dimples on the processed surface create oil reservoirs, significantly improving friction and wear characteristics. Additionally, by applying strong processing to the very surface of the metal, it achieves fine crystallization and enhances fatigue strength. 【Added Functional Surface Properties】 ■ Lubricity ■ Release properties ■ Fluid control ■ Durability ■ Optical properties *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"DLC coating" is a coating technology that, despite being a thin film of approximately 1μm (1/1000mm), possesses various characteristics such as high hardness, wear resistance, low friction, and low adhesion. Our company has successfully developed a technology that combines DLC coating with WPC treatment. This forms a smooth oil reservoir, enhances wear resistance, and the hard coating further prolongs its effectiveness. 【Features】 ■ Reduces friction ■ Suppresses oil temperature rise and deterioration ■ Improves response and contributes to smooth operation ■ Increases wear resistance, leading to longer component lifespan ■ Maintains good vehicle condition, resulting in cost reduction *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"DLC (Diamond-Like Carbon)" is a coating technology that, despite being a thin film of about 1 micron, possesses various characteristics such as high hardness, low friction, and low adhesion. The adoption of this technology has rapidly increased in top categories of motorsports, including F1 and MotoGP, as well as in recent eco-cars and high-performance cars. By combining it with our WPC treatment, we have successfully enhanced the performance and durability of DLC. 【Features】 ■ Low friction coefficient ■ Wear resistance ■ Scuff resistance ■ Low aggressiveness ■ Improved initial break-in properties *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This document explains the prevention of adhesion of food powders through texturing and the improvement of flow characteristics. It introduces the prevention of adhesion of food powders using WPC treatment, the mechanisms of adhesion suppression, and the evaluation of surface morphology. Our company is currently conducting optimization of texturing based on the establishment of measurement methods such as surface free energy measurement, observation of adhering powders, and Fourier transform, while also implementing a trial-and-error approach to optimization. 【Contents】 ■ Introduction ■ Prevention of adhesion of food powders using WPC treatment ■ Mechanisms of adhesion suppression ■ Evaluation of surface morphology ■ Conclusion *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We will introduce measures and enhancements for the weak points of the 86/BRZ, assuming high loads during circuit driving. In the case of the 86/BRZ, the CVJ runs directly under the exhaust, making it susceptible to heat damage, and additionally, due to the influence of VSC, there are many occurrences of CVJ breakage. By applying WPC treatment, we increase fatigue strength while simultaneously achieving a temperature suppression effect through reduced friction, thereby improving the durability of the CVJ. 【Related Products (Partial)】 ■ CVJ (Constant Velocity Joint) ■ Shift Fork Shaft / Bush ■ Synchro ■ 4-Speed Collar ■ Complete Transmission ■ Recommended Transmission Oil for 86/BRZ *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"WPC processing" is a surface modification technology that involves mixing fine particles of a material suited to the purpose with a compressible gas and colliding them at high speed onto the surface of metal products. By introducing strong processing into the local areas of the surface, it is possible to add fine crystal layers, nano crystal layers, and compressive residual stress. Additionally, it forms micro dimples on the surface, which enhances friction and wear characteristics due to shape effects such as oil reservoirs. 【Added Functional Surfaces】 ■ Lubricity ■ Release properties ■ Fluid control ■ Durability ■ Optical properties *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This document is a technical material on the industrial applications and challenges of DLC films. It explains the overview and types of DLC, deposition methods, trouble factors and challenges, as well as structure and characteristics, hardness measurement, structure/density, adhesion properties, and more. DLC is increasingly being used in a wide range of applications, including tools, moving parts, and medical devices. [Contents] ■ Introduction ■ What is DLC? ■ Characteristics of DLC ■ Industrial applications of DLC films and composite technology with WPC treatment ■ Conclusion *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"WPC processing" is a technology that modifies metal surfaces by mixing fine particles with a compressible gas and causing high-speed collisions with the metal surface. The modified surface becomes harder and changes shape into tiny dimples, which improves friction and wear characteristics. Additionally, by colliding fine particles at high speeds, the surface is refined, compressive residual stress is imparted, and toughness is enhanced. 【Features】 ■ Reduced friction ■ Wear prevention ■ Oil film retention effect ■ Increased fatigue strength *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The micro-dimple treatment creates uneven surfaces that are comparable in size to common bacteria. For example, bacteria can move freely on a stainless steel mirror surface, but on stainless steel treated with micro-dimples, the formed uneven surfaces hinder their ability to move and operate freely. Additionally, the uneven surfaces are thought to cause inhibition of flagellar movement, leading to self-damage in bacteria, which results in antibacterial effects.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We provide WPC treatment (Food) that can be used safely and securely, as there are no causes for foreign matter contamination due to surface modification treatment rather than coating. Any type of metal other than resin can be treated. We are particularly skilled in treating stainless steel for food-related applications. We can also provide test reports from official food testing institutions. Please feel free to contact us if you have any requests. 【Service Contents】 01. WPC Treatment (Microparticle Collision Method) 02. 3D Wrapping 03. Short Pulse Laser Processing 04. DLC Coating *For more details, please download the PDF or contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

WPC processing is a type of metal surface treatment that, unlike coatings, is a surface modification that does not peel off. The fine dimpled surface imparts slip resistance and oil retention, demonstrating excellent release properties in retainers, chutes, and hoppers. It reduces the risk of foreign matter contamination due to coating peeling and significantly decreases equipment management costs. There are no residues left on the equipment, making it safe for use in a wide range of fields, including food and medical applications. 【Features】 ■ Lower cost than coatings ■ Good cleanability ■ Improved roller maintenance ■ Excellent wear resistance ■ Non-toxic and safe for the human body *For more details, please request materials or view the PDF data from the download.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration