Metal surface treatment "WPC treatment" [Since it is surface modification, it will not peel off!]

Unlike coatings, this is a cutting-edge metal surface modification that does not peel off because it is a surface modification!

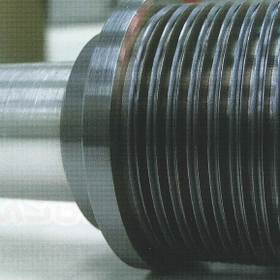

WPC processing is a type of metal surface treatment that, unlike coatings, is a surface modification that does not peel off. The fine dimpled surface imparts slip resistance and oil retention, demonstrating excellent release properties in retainers, chutes, and hoppers. It reduces the risk of foreign matter contamination due to coating peeling and significantly decreases equipment management costs. There are no residues left on the equipment, making it safe for use in a wide range of fields, including food and medical applications. 【Features】 ■ Lower cost than coatings ■ Good cleanability ■ Improved roller maintenance ■ Excellent wear resistance ■ Non-toxic and safe for the human body *For more details, please request materials or view the PDF data from the download.

Inquire About This Product

basic information

**Expected Effects of WPC Treatment** - Reduced sticking of noodles - Safe to use due to the non-toxic coating - Higher hardness and durability compared to fluorine coatings, leading to reduced maintenance costs - Improved roller maintenance - Lower cost compared to coatings, etc. *For more details, please refer to the catalog or feel free to contact us.*

Price range

Delivery Time

Applications/Examples of results

[Achievements] ■ Noodle manufacturing factory for a major convenience store chain, among others *For more details, please refer to the catalog or feel free to contact us.*

catalog(1)

Download All CatalogsCompany information

As a leading company in WPC processing, we achieve further reduction in friction and improvement in wear resistance and seizure resistance by combining it with other surface treatments such as DLC/PVD coating. WPC processing continuously shot-peens the metal surface with micro-sized media, generating residual compressive stress on the surface while simultaneously forming countless micro-dimples, significantly improving the fatigue strength and sliding characteristics of sliding parts. Fujii WPC Co., Ltd. boasts a wide range of processing achievements in industrial fields, from automotive parts to molds, cutting tools, and other tools, as a leading company in WPC processing. With composite processing using DLC coating, high-quality coatings have become possible for aluminum materials, which were previously difficult to coat. Additionally, by applying WPC as a pre-treatment for PVD coatings on molds, cutting tools, and other tools, we can further enhance the excellent performance of PVD. The lifespan of automotive parts, metal components, molds, cutting tools, and other tools can be increased several times! Further durability and friction reduction can be expected through composite processing combined with nitriding, carburizing, high-frequency hardening, and coating. We offer short delivery times, and orders can be placed from just one piece, including composite processing.