1~34 item / All 34 items

Displayed results

Filter by category

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us Online1~34 item / All 34 items

Filter by category

The "Kaiserslave Method (RC Construction)" is a construction method in which truss-reinforced half precast (PCa) slabs manufactured at a precast factory are laid on a concrete frame (formwork) at the construction site. After placing the remaining rebar on top, concrete is poured to construct the floor. The truss-reinforced half PCa slabs also serve as formwork, reducing the need for temporary materials and ensuring a safer work environment with fewer materials. Feel free to leave proposals and drawings to us. If you have any requests, please do not hesitate to consult with our company.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Kaiserslave Method (Steel Structure)" is a construction method where truss-reinforced half precast (PCa) slabs manufactured in a precast factory are laid on a steel frame (steel structure) at the construction site. After reinforcing the remaining rebar on top, concrete is poured to construct the floor. The truss-reinforced half PCa slabs also serve as formwork, reducing the need for temporary materials and ensuring a safer site environment with fewer materials. The ceiling surface will be finished in concrete. Feel free to leave proposals and drawings to us. If you have any inquiries, please do not hesitate to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Kaiser Void Slab Method" is a void slab construction method that arranges polystyrene void forms within the slab cross-section. Truss-reinforced half PCa panels with the void forms attached are laid out at the construction site, and the upper portion is constructed to create the floor. This method allows for an increase in slab rigidity without increasing slab weight, achieving a clean space without small beams. [Applications] - Trusses - Floor slabs - Half PC *For more details, please refer to the related links or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Kaiser Balcony Construction Method (RC Structure)" involves fully utilizing precast concrete (PC) for the tip of the balcony that connects to the concrete structure, and addressing it with half precast concrete panels with truss reinforcement. The tip of the balcony is difficult to construct due to the presence of drainage channels and handrails, requiring advanced techniques. By manufacturing such high-difficulty site work in a specialized PC factory, it is possible to ensure quality while simplifying the process. Please feel free to leave proposals and drawings to us. If you have any inquiries, do not hesitate to contact our company.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Kaiser Balcony Construction Method (Steel Structure)" involves fully precasting the tip of the balcony that connects to the steel frame (S structure) and using half precast panels with truss reinforcement. The tip of the balcony is complicated due to the presence of drainage channels and handrails, requiring advanced construction techniques. By manufacturing the truss-reinforced half precast panels at a specialized precast factory, we can simplify these challenging on-site tasks while ensuring high quality. This eliminates the need for cantilever beams, resulting in a cleaner finish. Feel free to leave proposals and drawings to us. If you have any inquiries, please do not hesitate to contact our company.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "nose tip PC" is a precast (PCa) component that fully utilizes precast concrete at the tip of the balcony. After laying the vertical and horizontal reinforcement bars in the conventional structure (formwork) and arranging the remaining rebar, concrete is poured to achieve integration as a precast (PCa) member. By manufacturing it at a specialized precast (PCa) factory, it contributes to shortening the construction period and allows for the simplification of complicated and difficult on-site work while ensuring high quality and safety. Since it is a relatively lightweight component, large heavy machinery is not required. Feel free to leave proposals based on drawings to us. If you have any requests, please do not hesitate to consult with our company.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Marion PC" is a non-structural decorative column component used on balconies and similar areas. Various finishes are required for this component, and we propose solutions for precasting (PCa) by leveraging the technology we have cultivated over many years. Please feel free to leave proposals based on drawings to us. If you have any requests, do not hesitate to consult with our company.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

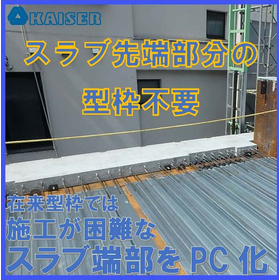

The 'Extended Slab PC' is a precast component that fully integrates the reinforcement and concrete of the upper anchoring bars at the tip of the extended slab between the curtain wall and beam, which is considered difficult to construct with conventional formwork. It also accommodates embedded components such as fastening hardware, streamlining complicated and challenging tasks on site. This enables efficient construction while ensuring high safety and reliability. 【Features】 ■ Effective in areas that are difficult to construct! ■ Manufactured at a dedicated PCa factory! ■ Significantly contributes to shortening construction time while maintaining high quality! ■ Compatible with embedded components such as fastening hardware! *For details, please download the PDF or contact us directly.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Kaiser PCF Method (Exterior Wall)" involves transporting truss-reinforced half precast concrete (PCa) panels manufactured at a precast factory to the construction site, where they are erected, lifted, temporarily supported, leveled, positioned, fastened, reinforced on-site, and then formed and poured with concrete to construct the walls. By utilizing precast concrete (PCa), not only is the construction period shortened, but it also serves as a formwork for the exterior wall, reducing the need for temporary materials and ensuring a safer work environment with fewer materials. It is also possible to specify it as a seismic wall (TBTC Evaluation No. 18001). Feel free to leave proposals and drawings to us. If you have any inquiries, please do not hesitate to contact our company.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Kaiser PCF Method (Foundation)" involves transporting truss-reinforced half precast concrete (PCa) panels, manufactured at a precast factory, to the construction site, where they are erected, lifted, temporarily supported, leveled, positioned, fastened, reinforced on-site, and constructed into walls through formwork installation on the interior side and concrete pouring. By utilizing precast concrete (PCa), not only is the construction period shortened, but it also serves as an external formwork, reducing the need for temporary materials and ensuring a safer site environment with fewer materials. Adopting this method eliminates the need for formwork dismantling, allowing for early backfilling. It can also be used as a substitute for the foundation footing's temporary formwork. Feel free to leave proposals and drawings to us. If you have any inquiries, please do not hesitate to contact our company.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Kaiser System Stair" consists of one wall column precast component per floor and two step floor precast components. The wall columns are connected vertically using a grout sleeve joint. Additionally, the step floors are integrated with the wall columns using screw rebar and special nuts. Please feel free to consult with us when you need assistance. 【Applications】 ■ Full PC *For more details, please refer to the related links or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

By manufacturing stairs that require complex and advanced construction techniques in the factory, we contribute to shortening the construction period and make it possible to omit high-difficulty on-site work while ensuring quality. We propose precast stairs that best meet on-site needs, such as precast components for the landing of X stairs, precast components for the intermediate wall constructed on-site, and precast components that integrate walls and landings. Please feel free to leave proposals based on drawings to us. When you need assistance, do not hesitate to consult with our company.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "PC stairs (outdoor)" are manufactured in a specialized PCa (precast) factory, which requires advanced technology and is difficult to construct, contributing to a reduction in construction time and allowing for the omission of complicated and challenging on-site work while ensuring quality. *Includes precast components integrated with walls and landings, and with high handrails, etc. Feel free to leave proposals based on drawings to us as well. Please do not hesitate to consult with our company when you need assistance.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Parapet PC (RC structure)" is a component that fully utilizes precast concrete (PCa) for the parapet at the top floor. It integrates with the structure using anchoring bars, but it is also possible to achieve integration with the structure by installing half precast (PCa) panel parapet components. By manufacturing at a specialized precast (PCa) factory, it contributes to shortening the construction period and allows for the omission of high-difficulty on-site work while ensuring quality. Please feel free to leave proposals and drawings to us. When you need our services, do not hesitate to consult with us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Parapet PC (Steel Structure)" is a building material that achieves a reduction in construction time and an improvement in construction quality through the full precasting (full PCa) of parapets installed at the top floor. When integrating with the main structure, in addition to fixing with anchor bars, it is also possible to lay half precast panel parapet components to achieve integration. This simplification of the process contributes to alleviating labor shortages. Our company leverages its strengths as a fabless manufacturer to select factories that meet design and delivery requirements from multiple partner factories, providing components accordingly. 【Features】 ■ Compatible with steel structures ■ Simplifies processes and contributes to reduced construction time ■ Capable of providing precast components tailored to design *For more details, please refer to the materials available for download in the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"Structural body PCa (precast) components (columns)" reduce the time and labor required for traditional on-site formwork, rebar placement, concrete pouring, and curing by utilizing precast methods, achieving high quality, shortened processes, and consideration for the environment. We have a network of manufacturing partner factories (PC factories) capable of producing column PCa (precast) tailored to your project requirements. We can also produce beam PCa (precast) as part of the structural body construction, and we welcome inquiries regarding proposals based on PCa (precast) drawings. Please feel free to consult with us when needed.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"Structural frame PCa (precast) components (beams)" can achieve high quality, shortened construction time, and environmental considerations by precasting the time and work required for traditional on-site formwork, rebar placement, concrete pouring, and curing. We have a network of manufacturing partner factories (PC factories) capable of producing column PCa (precast) and will manufacture beam PCa (precast) tailored to your project requirements. We can also produce it together with column PCa (precast), which is part of structural frame construction, and we welcome proposals based on PCa (precast) drawings. Please feel free to consult us when you need our services.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"PC Curtain Wall" is a non-structural wall component that is installed using hardware retrofitted to the building structure. It is a component that requires various finishes, and we propose solutions for precasting (PCa) by leveraging the technology we have cultivated over many years. Please feel free to leave the proposals, including drawings, to us. If you have any inquiries, please do not hesitate to contact our company.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Ramp PC" is a precast (PCa) component that integrates the outer walls of the rampway (ramp) associated with logistics warehouses by laying horizontal and vertical reinforcement bars in the structure and then placing concrete after arranging the remaining rebar. By manufacturing it at a specialized PCa factory, it contributes to shortening the construction period and allows for the simplification of complicated and difficult on-site work while ensuring high quality and safety. Additionally, we propose solutions utilizing the cultivated PCa technology to address challenges that were difficult with conventional methods. Feel free to leave the drawing proposals and other requests to us. Please do not hesitate to consult with our company when needed.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Canopy PC" is a PCa (precast) component that is either fully PCa (precast) or a half PCa (precast) slab with truss reinforcement. It is laid on the structure (formwork), and after placing the remaining rebar, concrete is poured to achieve integration. By manufacturing it in a specialized PC factory, quality can be ensured while also allowing for simplification. 【Features】 ■ Contributes to high quality, cost reduction, and shortened construction period ■ Can be discussed together, including the feasibility of precasting ■ Reduces manpower for work at the canopy tip Please feel free to leave proposals and drawings to us. If you have any inquiries, please do not hesitate to contact us. *For more details, please download the PDF or contact us directly.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Dog Run PC" is a PCa (precast) component that integrates a truss-reinforced half PCa slab with a full PCa (precast) tip of 1CS (Canchis Lab). After laying it on the structure (formwork) and arranging the remaining rebar, concrete is poured to achieve integration. By manufacturing it at a specialized PC factory, quality can be ensured while allowing for simplification. Please feel free to leave any proposals or drawings to us. If you have any requests, do not hesitate to consult with our company.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "waist wall PC" is a precast (PCa) component used for exterior walls in logistics warehouses, where vertical and horizontal reinforcement bars are installed in the structure, and after arranging the remaining rebar, concrete is poured to achieve integration. By manufacturing it in a specialized PCa factory, it contributes to shortening construction periods and allows for the simplification of complicated and difficult on-site work while ensuring high quality and safety. Additionally, we propose solutions utilizing the cultivated PCa technology to address challenges that were difficult to tackle with conventional methods. Please feel free to leave proposals, including drawings, to us. If you have any inquiries, do not hesitate to consult with our company.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Double Wall Method" involves manufacturing double walls in a precast factory, installing them at the construction site, connecting them vertically and horizontally with PCa panels, and integrating them by pouring concrete. It consists of precast components formed by two half PCa panels facing each other and connected with truss members. Since it is lighter compared to full precast, it is effective in addressing lifting challenges. Please feel free to leave any proposals or drawings to us. If you have any inquiries, do not hesitate to consult with our company.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We offer the 'Kaiser BARD slab', which excels in fatigue durability due to the integration effect of truss reinforcement. Pre-stress is introduced using a pre-tension method in the direction perpendicular to the bridge axis, and a half precast PC slab with Kaiser truss reinforcement is installed on top of the girders to enhance the integration with cast-in-place concrete. After arranging the upper reinforcement bars, fresh concrete is poured to form an integrated slab, which serves as both scaffolding and formwork. Please feel free to contact us if you have any inquiries. 【Features】 ■ The Kaiser truss reinforcement serves as a reliable spacer for on-site reinforcement, significantly improving workability and allowing for substantial reductions in construction time and labor. ■ The integration effect of the Kaiser truss reinforcement provides excellent fatigue durability. ■ It can be constructed without support, serving as both formwork and scaffolding, eliminating the need for assembly and disassembly of support structures. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Kaiser Railway Elevated Bridge Slab" is a rational slab that uses high-quality precast components manufactured in a factory, enabling the construction of elevated bridges that excel in durability and cost-effectiveness. Compared to conventional cast-in-place slabs, it does not require formwork or shoring, which reduces construction noise and minimizes material yard requirements, contributing to shorter construction timelines and lower total costs. Please feel free to contact us if you have any inquiries. 【Features】 ■ Shortened construction timeline ■ Possible to construct directly above live lines without shoring ■ Reduced life cycle costs ■ Existing slab designs can be applied directly ■ High safety standards ■ Uniform quality ■ Improved quality of structures *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Kaiser Railway Elevated Bridge Slab" is a rational slab that uses high-quality precast (PCa) components manufactured in a factory, allowing for the construction of elevated bridges that excel in durability and cost-effectiveness, and is installed on cast-in-place beams. Since the lower half of the slab cross-section is made of PCa, it can be constructed directly above live lines. Additionally, by casting the upper half of the slab on-site, the structure becomes integrated. The intermediate and cantilever sections are unified, eliminating the need for formwork and shoring. Compared to conventional cast-in-place slabs, it reduces construction noise and material yard requirements, contributing to shortened construction schedules and reduced total costs. Please feel free to contact us if you have any inquiries. 【Features】 ■ Shortened construction schedule ■ Possible to construct directly above live lines without shoring ■ Reduced life cycle costs ■ Existing slab designs can be directly applied ■ High safety ■ Uniform quality ■ Improved quality of structures

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is a mid-floor slab for a shield tunnel based on the "Kaiser Railway Viaduct Slab." It is a rational slab made using high-quality precast (PCa) components manufactured in a factory, excelling in durability and cost-effectiveness. To enhance the integration with cast-in-place concrete, a half-precast mid-floor slab with Kaiser truss reinforcement is installed. After reinforcing the upper rebar as a formwork, fresh concrete is poured to form an integrated mid-floor slab. 【Features】 ■ The Kaiser truss reinforcement serves as a reliable spacer for on-site reinforcement, significantly reducing construction time and labor through improved workability. ■ The integration effect from the Kaiser truss reinforcement provides excellent fatigue durability. ■ It can be constructed without supports, serving as both formwork and scaffolding, eliminating the need for assembly and disassembly of support structures.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Kaiser Railway Elevated Bridge Slab" is a rational slab that constructs a durable and economical elevated bridge using high-quality factory-produced precast (PCa) components, which are installed on precast beams. Since the lower half of the slab cross-section is made of PCa, construction directly above live wires is possible. Additionally, by casting the upper half of the slab on-site, the structure becomes integrated. The intermediate and cantilever sections are integrated, eliminating the need for formwork and shoring. Compared to conventional cast-in-place slabs, it reduces construction noise and material yard requirements, contributing to shorter construction time and lower total costs. Please feel free to contact us if you have any inquiries. 【Features】 ■ Shortened construction time ■ Possible to construct directly above live wires without shoring ■ Reduced life cycle costs ■ Conventional slab designs can be directly applied ■ High safety ■ Uniform quality ■ Improved quality of structures

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is a shield tunnel intermediate floor slab. It is a rational intermediate floor slab made of high-quality precast components manufactured in a factory, excelling in durability and cost-effectiveness. To enhance the integration with cast-in-place concrete, an HPCa (half precast) intermediate floor slab with Kaiser truss reinforcement is installed. After reinforcing the upper steel bars using the formwork as a combined function, fresh concrete is poured to form an integrated intermediate floor slab. ★Exhibiting at Highway Techno Fair 2024★ 【Features】 ■ The Kaiser truss reinforcement serves as a reliable spacer for on-site reinforcement, significantly improving workability and enabling substantial process shortening and labor saving. ■ The integration effect from the Kaiser truss reinforcement provides excellent fatigue durability. ■ It can be constructed without supports, serving as both formwork and scaffolding, eliminating the need for assembly and disassembly of support structures. *For more details, please download the PDF or contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is a rational top slab made using high-quality precast components manufactured in the factory, excelling in durability and cost-effectiveness. To enhance the integration with cast-in-place concrete, an HPCa (Half Precast) top slab with Kaiser truss reinforcement is installed. After reinforcing the upper steel bars for use as formwork, fresh concrete is poured to form an integrated top slab. 【Features】 - The Kaiser truss reinforcement serves as a reliable spacer for on-site reinforcement, significantly improving workability and allowing for substantial reductions in construction time and labor. - The integration effect provided by the Kaiser truss reinforcement results in excellent fatigue durability. - It can be constructed without supports, serving as both formwork and scaffolding, eliminating the need for assembly and disassembly of support structures.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is a precast component designed with natural stone materials and fine reliefs on the surface of truss-reinforced HPCa (half precast) panels, taking into consideration the urban landscape. The Kaiser wall, manufactured in a precast factory, is transported to the construction site, erected, lifted, temporarily supported, positioned, fixed, reinforced on-site, formwork constructed, and concrete poured to build the retaining wall.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Kaiser Truss" is a three-dimensional truss rebar that integrates a top chord and two bottom chords formed continuously in a mountain shape through electric resistance welding. It ensures the integrity of precast and cast-in-place concrete, secures the rigidity of thin plates, and exhibits various effects such as functioning as a suspension fixture or spacer. Please feel free to contact us if you have any inquiries. 【Specifications (partial)】 ■ Truss height: 65mm to 300mm (in 5mm increments) ■ Truss width: 80mm to 100mm (varies with truss height) ■ Truss length: manufactured in 100mm increments according to order * For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"Kaiser Truss" is a three-dimensional truss rebar that integrates a top bar and two bottom bars formed in a mountain shape through continuous molding, using electric resistance welding. It ensures the integrity of precast and cast-in-place concrete, maintains the rigidity of thin plates, and exhibits various functions such as serving as a hanging fixture or spacer. 【Specifications (partial)】 ■ Truss height: 65mm to 300mm (in 5mm increments) ■ Truss width: 80mm to 100mm (varies with truss height) ■ Truss length: manufactured in 100mm increments according to order

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"Kaiser Truss" is a three-dimensional truss rebar that integrates one top bar and two bottom bars using a mountain-shaped continuous forming lattice bar through electric resistance welding. The material is SD345, and the top bar can be up to D16. Additionally, the height of the Kaiser Truss rebar can accommodate up to 400mm.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration