1~17 item / All 17 items

Displayed results

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us Online1~17 item / All 17 items

At the bottom and top, we use modified asphalt sheets that excel in waterproof reliability and workability on flat surfaces, while on the sides, we employ urethane spray that is excellent for side workability and processing of penetrations, creating a truly hybrid underground waterproofing method. Underground waterproofing is divided into various parts: bottom, sides, and top, and the construction methods, such as pre-application and post-application, differ, which means that the waterproofing of each part is connected to form a waterproof layer. Therefore, a single material is often insufficient for waterproofing, and there are many cases where a combination of multiple materials is desirable. Tajima Roofing, as a comprehensive waterproofing manufacturer, promotes the hybridization of underground waterproofing by leveraging its own materials, methods, and connection technologies.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

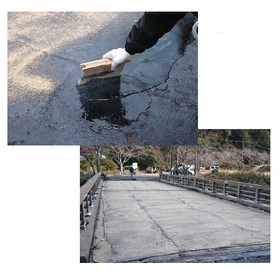

The TS Guard method is a composite waterproofing system that involves applying the acrylic resin-based penetrating waterproof material "TS Guard" followed by the asphalt heating type "Deck Coat ND," creating a more robust waterproofing effect with a two-layer coating. TS Guard penetrates and hardens within the concrete deck, making it a two-component reactive waterproofing material that can repair even fine cracks. By adding a curing accelerator, it can progress to the next stage in a short time even at low temperatures (5°C). Deck Coat ND allows for speedy and seamless waterproofing construction, characteristic of heating types, and has high adhesion and durability to asphalt pavement. By combining these two types of waterproofing, this method exhibits enhanced waterproof performance.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce the "Altax Spray Parking Lot Specification," a super-fast curing polyurethane coating waterproofing handled by Tajima Roofing. The Altax Spray Parking Lot Specification is a method that involves spraying high-strength, super-fast curing polyurethane and forming a waterproof membrane by layering ceramic aggregates. This method is suitable for waterproofing work in areas where vehicles directly drive over (compatible with vehicles up to 4 tons). It is a lightweight and wear-resistant method that is effective for renovation work on existing parking lot waterproofing. Depending on the frequency of vehicle use and the amount of wear, we offer two specifications: "OPA-30Q-SP" for general parking areas and "OPA-50Q-SP" for parking lot ramps. 【Features】 ■ High-strength, super-fast curing polyurethane waterproofing material applied using a dedicated spray system ■ Instantly forms a coating with excellent safety, chemical resistance, and crack-following properties ■ No toxic gases are generated during the chemical reaction at the time of mixing ■ High work safety with minimal odor during construction ■ Significant labor savings and a substantial reduction in construction time are possible *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Altarx Spray Underground Waterproofing Method" forms a seamless and high-quality waterproof coating. It accommodates both post-construction and pre-construction methods for external waterproofing in underground structures, creating a waterproof layer without seams even on complex surfaces. By using ultra-fast curing Altarx spray materials and dedicated spraying machines, it forms a high-quality waterproof layer in a short time. Particularly in large-scale projects, it allows for significant reductions in construction time compared to conventional sheet waterproofing. 【Features】 ■ Forms a high-quality coating with excellent durability ■ Reliable watertightness with a seamless waterproof layer ■ Improves construction efficiency with dedicated spraying machines ■ Accommodates the complex shapes and conditions of underground structures *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Altax Spray UA Method (Pool Specification)" is a waterproofing method that uses "Altax Spray UA," which sprays polyurea resin waterproofing material with a dedicated spray machine, and a highly durable protective coating called "UA Coat." "UA Coat" excels in weather resistance, water resistance, and has high chemical resistance, maintaining its gloss over the long term. Using materials that excel in safety and durability, it forms a seamless and robust coating waterproof layer in a short construction period, protecting the structure over the long term without affecting the water quality of the pool facility. 【Features】 ■ Waterproofing method using "Altax Spray UA" and "UA Coat" ■ Forms a seamless and robust coating waterproof layer in a short construction period ■ Protects the structure over the long term without affecting the water quality of the pool facility *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Altarx Spray UA Method" is a technique that uses a specialized spray machine to apply a rapidly curing polyurea resin, forming a membrane that excels in safety, chemical resistance, and crack-following ability. This method is particularly suitable for large-scale applications such as water supply and tank facilities, as it forms a coating instantly. In facilities where water quality safety is crucial, such as drinking water supply systems, water tanks, agricultural irrigation channels, and fish farms, it demonstrates excellent performance as a safe and robust lining that protects both water and structures. 【Features】 - Construction using rapidly curing polyurea resin with a specialized spray system - Instantly forms a coating that excels in safety, chemical resistance, and crack-following ability - Particularly suitable for large-scale water supply and tank facilities - Complies with Japan Water Works Association (JWWA) K143 standards and Ministry of Health Ordinance No. 15 - No toxic gases are generated during the chemical reaction at the time of mixing - High work safety with minimal odor generation during construction - Enables labor-saving construction and significant reduction in construction time *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Glass Barrier Sheet AS" is a high-performance new weed control sheet that utilizes modified asphalt technology used in rooftop waterproofing and civil engineering waterproofing work. With a structure that excels in durability and strength, it completely blocks light and rainwater, suppressing the growth of weeds and maintaining its weed control effect over the long term. The joint sections between sheets are strongly bonded simply by overlapping them using "delayed adhesion technology," allowing for safe construction work without the use of fire or solvents. 【Features】 ■ Flexible and moderately weighted, allowing for good compatibility with the substrate ■ Resistant to ultraviolet rays, boasting a long service life ■ The bonding between sheets uses a new delayed adhesion technology ■ Easily repositionable immediately after installation *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"Elastite" is a civil engineering joint material made by filling asphalt with mineral fibers and powders, rolling it into sheet form, and attaching asphalt felt to both sides. It has excellent water resistance and corrosion resistance, making it suitable for applications such as riverbank protection, dams, roads, and subways. With stable quality and moderate compressive strength, it helps maintain the integrity of concrete structures. [Features] - Due to the uniform asphalt mastic mixture, it offers long-term stability. - Excellent water resistance and corrosion resistance. - Possesses moderate compressive strength, keeping concrete structures sound. *For more details, please refer to the PDF document or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Revamp Method" is a construction technique that uses RV aqueous solutions or RV mortar containing a high concentration of lithium nitrite (LiNO2). Due to its high suppression effect, it prevents the intrusion of external deterioration factors. By allowing nitrite ions to permeate around the internal rebar, it generates a rust prevention effect for the entire internal rebar of concrete structures that have deteriorated due to salt damage and carbonation, thereby regenerating the passive film. This method is suitable for repairing the structural bodies of all reinforced concrete structures, including bridges, tunnels, roads, embankments, and subways. 【Features】 ■ Generates a rust prevention effect for the entire internal rebar and regenerates the passive film. ■ Creates a rust prevention environment for internal rebar through the diffusion of nitrite ions. ■ Prevents the intrusion of external deterioration factors (carbon dioxide and chloride ions) due to the high suppression effect of the rust prevention mortar. *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Gumlong Grass Guard" is a modified asphalt-based weed control and waterproof sheet designed to prevent rainwater infiltration into embankment surfaces for an extended period while maintaining its weed suppression effect. By using a highly durable modified asphalt waterproof sheet, it effectively blocks the water and light necessary for photosynthesis, achieving high weed control performance and a long lifespan. The auxiliary materials are also well-equipped, making detailed installation easy. It has excellent alkali resistance, allowing for use in conjunction with concrete structures. Additionally, it helps prevent the reduction of embankment strength and erosion caused by rainwater, facilitates maintenance-free operations such as grass cutting, and addresses public nuisance issues related to herbicide application and sources of pest outbreaks. 【Features】 ■ Lightweight at less than 3 kg/m2 ■ Excellent total cost due to dry construction methods ■ Prevents the proliferation of weeds and erosion of slopes due to rainwater over the long term ■ Highly durable new structure modified asphalt sheet ■ Jointly developed construction method with the Railway Technical Research Institute *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"Floor Coating ND" is a waterproofing material for bridge deck slabs made from a coating system using modified asphalt with added special polymers. It is a heated asphalt waterproofing material for coating-type deck waterproofing methods in road bridges, equipped with tensile performance that can adequately respond to various movements occurring in the deck. Additionally, the heated asphalt type allows for speedy construction, excels in construction efficiency, and can form a seamless waterproof layer, which is a characteristic of coating-type waterproofing materials. [Features] ■ Complies with the basic verification of the "Road Bridge Deck Waterproofing Manual" ■ Ensures excellent durability due to high-quality modified asphalt ■ Possesses low-temperature flexibility and can be used over a wide temperature range *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"Floor Plate Sheet J" is a cold adhesive waterproof sheet for bridge floor plates, coated with modified asphalt on a glass substrate that boasts high durability and excellent dimensional stability. It meets the quality standards of the basic verification tests in the Road Bridge Floor Plate Waterproofing Manual and integrates through melting due to rolling and the residual heat from paving, considering safety and the environment. The cold adhesive type can reduce CO2 emissions during construction and is characterized by relatively few occurrences of blistering (such as bulging) after waterproofing, making it suitable for areas with thin pavement thickness, such as sidewalks, and less affected by site constraints. 【Features】 ■ Cold adhesive type that integrates through melting due to rolling and residual heat from paving ■ Excellent temperature characteristics, usable over a wide temperature range ■ Superior workability without the need for special construction machinery ■ Excellent followability due to the combination of a robust substrate and high-quality modified asphalt *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The road bridge deck slab is a part that is subjected to severe conditions due to traffic loads through the pavement, and it tends to sustain damage easily. The "Deck Slab Sheet NW" is a waterproof sheet for bridge deck slabs that conforms to the basic verification tests of the road bridge deck waterproofing manual, designed for asphalt pouring application. It has excellent temperature characteristics and can be used over a wide temperature range. Its combination of a robust base material and high-quality modified asphalt boasts outstanding durability. 【Features】 ■ Specifically designed for the pouring type waterproofing method for road bridge deck slabs ■ Excellent temperature characteristics, usable over a wide temperature range ■ Equipped with tensile performance (tensile strength and elongation) to adequately respond to various movements occurring in the deck slab *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In "external waterproofing," a modified asphalt sheet called Gamron Fort is installed on the outside of the concrete structure. This allows for good workability and makes it easy to manage and verify quality and performance. Gamron Fort can be applied by peeling off the release paper, which reduces labor and generates almost no odors or smoke. Additionally, a space of about 1.0 to 1.5 meters is required between the retaining wall surface and the concrete surface of the structure. *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The high-reliability modified asphalt sheet "Gumron Fort" is applied to the retaining walls and slopes before the concrete is poured, connecting with the concrete that will be poured later to demonstrate its waterproofing function. Compared to the "post-pouring method," this underground waterproofing method allows for a narrower excavation range and eliminates the need for backfilling and other tasks, making it suitable for space-saving and improving work efficiency. The construction begins by securing the asphalt molded board "Balistar WP" as a base material for applying the waterproofing material to the retaining walls and slopes, followed by attaching Gumron Fort on top, after which the concrete is poured. *For more details, please refer to the PDF document or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "post-construction method" involves applying a waterproof layer after the concrete structure of an underground facility has been completed. After pouring the concrete, a primer is applied, followed by the attachment of "Gumron Fault." During backfilling after construction, protective materials (such as GS Protector) are applied to protect against damage during the backfilling process. This method is highly reliable as it allows for waterproofing to be applied directly to the concrete structure. It is necessary to secure a work area for waterproofing, making this method advantageous when there is ample land available. *For more details, please refer to the PDF document or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"Gumronfort" is a modified asphalt sheet for underground waterproofing, consisting of a high-strength, high-elasticity synthetic fiber non-woven fabric substrate that is impregnated and coated with modified asphalt. It is a fully adhesive layer type that reliably adheres to both the Gumron itself and the substrate simply by peeling off the release paper. The adhesive layer has extremely stable adhesion and fluidity characteristics over a wide temperature range, allowing for all-season application. 【Features】 ■ Fully adhesive layer type ■ All-season application possible ■ Durable non-woven fabric substrate with excellent stretch, tear, and tensile strength ■ Forms a reliable waterproof layer due to the substrate-following properties combined with rubberized asphalt *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration