1~10 item / All 10 items

Displayed results

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us Online1~10 item / All 10 items

At chemical giant Company A, the aging of equipment and concrete tanks was severe, and deterioration was quite noticeable. Although repairs were made every year, there were concerns within the company about whether they could maintain the current state and how long they could continue operations. Our company proposed a concept that allows for both the extension of the lifespan and the enhancement of functionality, based on the premise of utilizing existing tanks, achieving renovation without halting operations through meticulous investigation and consideration. As a result, we were able to achieve the extension of equipment lifespan and a significant reduction in running costs through renovation. **Effects of Renovation** **Extension of Equipment Lifespan** - Conducted seismic reinforcement work to avoid the risk of collapse during a major earthquake. - Significantly reduced investment costs compared to the construction of new tanks. **Significant Reduction in Running Costs** - Approximately 50% reduction in electricity consumption. - Approximately 70% reduction in sludge generation. - Recovery of methane gas from wastewater organic matter, leading to reduced fuel costs for the entire factory through energy creation. *For more details, please refer to the PDF document or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

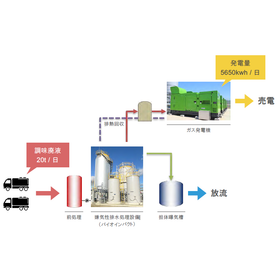

Nakata Foods is a food manufacturer based in Wakayama Prefecture, specializing in the production and sale of pickled plums, plum wine, and plum processed products. The plum seasoning wastewater generated during the pickling process is an extremely high-concentration wastewater exceeding BOD: 100,000 mg/l, making it difficult to treat with conventional wastewater treatment facilities. To utilize the plum seasoning wastewater as a biomass source, we introduced our anaerobic wastewater treatment facility, "Bio Impact." Previously treated as industrial waste, the plum seasoning wastewater can now be processed at a reduced cost thanks to the high-efficiency anaerobic wastewater treatment facility. This has significantly alleviated the burden on small and medium-sized businesses by allowing for acceptance at a lower cost than before. 【Facility Overview】 ■ Facility: Nakata Foods Biogas Power Plant ■ Start of Operation: April 2019 ■ Treatment Capacity: 20 tons/day (dedicated to plum seasoning wastewater generated from our own and local plum processing businesses) ■ Biogas Utilization Equipment: Diesel engine generators (60 kW x 6 units) ■ Annual Power Generation: Approximately 2 million kWh ■ Treated Water: Utilizes public sewer system *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"Aero Impact" is a fluidized bed biological membrane carrier treatment capable of handling high loads, reducing the installation area compared to the standard activated sludge method. By using the Moving Bed Biofilm Reactor (MBBR) method with a fluidized bed carrier, it achieves compactness, high performance, and easy maintenance. There is no need for sludge concentration management in the aeration tank or interface management in the settling tank. It reduces sludge volume through biological activity without the use of ozone or chemicals. 【Features】 ■ Achieves compactness, high performance, and easy maintenance ■ Capable of handling high loads ■ Reduces installation area compared to the standard activated sludge method ■ No need for sludge concentration management in the aeration tank or interface management in the settling tank ■ Reduces sludge volume through biological activity without the use of ozone or chemicals *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a case study of the fluidized bed biological membrane treatment system "Aero Impact," which our company handles. Company C, a chemical company, decided to increase production at Factory H due to strong sales, but faced the challenge of "not having space to enhance wastewater treatment." In response to this request from Company C, we conducted a study centered around the existing aeration tank using the fluidized bed biological membrane treatment system "Aero Impact." By introducing this product, we can significantly reduce investment costs by utilizing the existing aeration tank and sedimentation tank, and eliminating the need for additional dewatering equipment. [Overview] ■ Industry: Chemical Industry ■ Challenges: Space-saving, labor-saving, cost reduction ■ Product Introduced: Fluidized Bed Biological Membrane Treatment System "Aero Impact" *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a renovation case of our "RC Ranger." In a certain steel mill's wastewater treatment facility, the deterioration of the concrete aeration tank was severe, and water leakage from the tank was confirmed. However, there were constraints on the site that made it difficult to construct a new aeration tank. In response, we carried out repair work on the aeration tank using a temporary aeration tank and a high-speed coagulation sedimentation device. The high-speed coagulation sedimentation equipment also achieved the enhancement of the wastewater treatment facility's functions for future repurposing. Based on our experience and achievements as a plant manufacturer, we provide comprehensive proposals from deterioration diagnosis of the tank, repairs, installation of temporary equipment, operation, to renovation suggestions. [Customer Concerns] ■ It is difficult to construct a new aeration tank due to site constraints. ■ Since the factory operations cannot be halted, they have given up on a complete repair of the aeration tank. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"RC Ranger" is an environmental solution that provides thorough repairs without stopping operations. Based on our experience and achievements as a plant manufacturer, we offer comprehensive proposals ranging from deterioration diagnosis of tanks, repairs, installation of temporary facilities, operation, to renovation suggestions. From diagnosis to deterioration and seismic reinforcement, leave everything to us. 【Service Contents (Excerpt)】 ■ Temporary Red: Temporary aeration tanks, blowers, sedimentation tanks, temporary electrical instrumentation equipment, etc. ■ Repair Blue: Scaffolding equipment, column reinforcement, anti-corrosion painting, FRP lining, etc. ■ Operation Yellow: Mechanical equipment, operation control, operation management, sample collection. ■ Renovation Green: Space-saving, energy creation. ■ Inspection Pink: Scaffolding inspection, deterioration diagnosis. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company offers a "Renovation Service" aimed at extending the lifespan of existing equipment while also enhancing its functionality. We address issues such as aging, unstable processing, and high running costs associated with existing equipment, providing benefits such as stabilization, energy conservation, and energy creation. For innovation in existing equipment, please feel free to consult with us. 【Features】 ■ Aiming to extend the lifespan of existing equipment ■ Further enhancing functionality ■ Solving issues related to existing equipment ■ Providing various benefits *For more details, please refer to our catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

As an example of the renovation services we provide, we would like to introduce a case where we renovated equipment that had been in place for over 40 years, successfully extending its lifespan, enhancing its functionality, and achieving space-saving solutions. After renovating existing equipment that not only suffered from aging but also had seismic issues with the adjustment tank and aeration tank, we succeeded in extending its lifespan to allow for continued use for several decades. Additionally, by introducing anaerobic treatment for high-concentration wastewater, we strengthened its functionality, resulting in a 70% reduction in electricity and excess sludge. Furthermore, by removing the old adjustment tank, we were able to effectively utilize the idle land, achieving space-saving as well. We offer various benefits, including extending the lifespan of existing equipment, improving functionality, and space-saving solutions for wastewater treatment facilities. If you are considering renovating existing equipment, please feel free to contact us. [Implementation Overview] ■ Equipment that has been in place for over 40 years ■ Existing equipment suffers from aging and seismic issues with the adjustment tank and aeration tank *For more details, please refer to our catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We provide compact and energy-efficient systems for optimal treatment of factory wastewater, addressing issues such as water volume and load fluctuations, as well as oil separation. For water volume loads and high-concentration (high BOD) wastewater, significant load reduction and energy recovery can be achieved with "Bio Impact." Additionally, for SS (solid substances) and oil in the wastewater, the "Ad Sludge System" performs sludge mixing and adsorption treatment, preventing negative impacts on wastewater treatment. We will propose the optimal system for water treatment, so please feel free to consult with us. 【Features】 ■ Proposing optimal systems for water treatment ■ Providing compact and energy-efficient systems *For more details, please refer to our catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"Bio Impact" is an anaerobic wastewater treatment system capable of accepting medium to high concentration wastewater with BOD=500=10,000mg/l. Since aeration is not required, it significantly reduces the power costs for wastewater treatment, is resilient to load fluctuations, and generates a small amount of sludge. It is also applicable to various food manufacturing wastewater, including those from the food and beverage industry, confectionery, seasonings, and processed foods. With a rich lineup, we propose the optimal system for your water volume, water quality, and construction conditions. Please feel free to consult us. 【Features】 ■ Capable of accepting medium to high concentration wastewater with BOD=500=10,000mg/l ■ No heating required ■ Resilient to load fluctuations ■ Low sludge generation ■ 100 successful cases *For more details, please refer to the catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration