1~35 item / All 35 items

Displayed results

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us OnlineBefore making an inquiry

Download PDF1~35 item / All 35 items

In the vicinity of the planned construction site for a detached house (two-story lightweight steel frame) in Saitama Prefecture, trains frequently pass by, raising concerns about the impact of railway vibrations on the living environment. Therefore, the 'WIB method' was implemented directly beneath the house. Vibration measurements taken before and after the construction confirmed a reduction effect of approximately 4dB in the horizontal direction and about 6dB in the vertical direction, effectively halving the railway vibrations. 【Case Overview】 ■ Construction Location: Saitama Prefecture ■ Client: Sanyu Soil Engineering Co., Ltd. ■ Vibration Source: Railway vibrations ■ Preservation Target: Houses along the railway ■ Countermeasure Work: Plate-type WIB method (honeycomb cell type) ■ Construction Position: Directly beneath the receiving side *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In residential areas of Tokyo, vertical vibrations caused by passing trains were affecting the living environment. Therefore, during the reconstruction of the housing, the 'WIB method' was implemented directly beneath the residences. Vibration measurements on the ground were conducted before and after the countermeasures. As a result, a reduction of 4 to 5 dB was confirmed. 【Case Summary】 ■ Location: Tokyo ■ Client: Mitsui Home Co., Ltd. ■ Vibration Source: Railway vibration ■ Preservation Target: Houses along the railway ■ Countermeasure Method: Plate-type WIB (honeycomb cell type) ■ Installation Position: Directly beneath the receiving side *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Vibrations from trains passing near the residential development site in Kanagawa Prefecture (currently Fujisawa SST) raised concerns about their impact on the living environment after the construction of the houses. In response, the 'WIB method' was implemented directly beneath each house. Vibration measurements on the ground were conducted before and after the countermeasures. When evaluating the vibration levels for each type of train, an average reduction of 6 dB in the horizontal direction and 5 dB in the vertical direction was confirmed. [Case Overview] ■ Location: Kanagawa Prefecture ■ Client: Ando & Associates Co., Ltd. ■ Vibration Source: Railway vibrations ■ Preservation Target: Residential houses along the railway (total of 11 buildings) ■ Countermeasure Work: Plate-type WIB method (honeycomb cell type) ■ Construction Position: Directly beneath the receiving side *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In residential houses along the roads in Tokyo, vibrations from large vehicles were propagating, and vertical vibrations were affecting the living environment. Therefore, during the rebuilding of the houses, the 'WIB method' was implemented directly beneath the residences. Vibration measurements were conducted before and after the countermeasures within the buildings. As a result, a reduction of 3-6 dB on the first floor and 4-5 dB on the second floor was confirmed, improving livability. [Case Summary] ■ Location: Tokyo ■ Client: Sekisui Heim Corporation ■ Vibration Source: Road traffic vibrations ■ Preservation Target: Houses along the road ■ Countermeasure Method: Plate-type WIB (honeycomb cell type) ■ Installation Position: Directly beneath the receiving side *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Some plots of a residential development in Saitama Prefecture face a railway, raising concerns about the impact on the living environment after the construction of the houses. Therefore, the 'WIB method' was implemented directly beneath the houses. Vibration measurements were conducted before and after the countermeasures. Dominant vibrations in the range of 10 to 20 Hz were reduced by 6 to 12 dB (to 1/4 to 1/2 of the original vibration), keeping the vibration level below 60 dB. 【Case Overview】 ■ Location: Saitama Prefecture ■ Client: Housing manufacturer ■ Vibration source: Railway vibrations ■ Preservation target: Houses along the railway (total of 9 buildings; 5 buildings + 4 buildings) ■ Countermeasure work: Plate-type WIB method (honeycomb cell type) ■ Installation position: Directly beneath the receiving side *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

A portion of a residential development site in Saitama Prefecture faces a railway, raising concerns about the impact on the living environment after the construction of homes. Therefore, the "WIB method" was implemented directly beneath the residences. Additionally, to ensure greater vibration reduction, countermeasures were also installed directly beneath the unused land. Vibration measurements were conducted before and after the countermeasures, resulting in a reduction of dominant vibrations in the 10-20Hz range by 10-14dB (to 1/5 to 1/3 of the original vibrations), keeping the vibration level below 60dB. [Case Overview] ■ Location: Saitama Prefecture ■ Client: Housing manufacturer ■ Vibration source: Railway vibrations ■ Preservation target: Residential buildings along the railway (a total of 4 buildings + unused land) ■ Countermeasures: Plate-type WIB method (directly beneath residences) and wall-type WIB method (directly beneath unused land) honeycomb cell type ■ Installation position: Directly beneath the receiving side (beneath residences) and along the propagation path (beneath unused land) *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The planned construction site for housing in Kanagawa Prefecture was experiencing traffic vibrations transmitted from the elevated bridge and the road in front of the site. As a countermeasure, we implemented measures directly beneath the apartment building. The vibrations from the elevated bridge were predominantly at 4Hz, while those from the road in front of the site ranged from 12.5 to 20Hz. We designed the "WIB method" to address each of these vibrations. As a result, we reduced the 4Hz vibrations by approximately 5dB and the 12.5 to 20Hz vibrations by about 10dB, resulting in vibrations that did not affect livability. [Case Summary] ■ Construction Location: Kanagawa Prefecture ■ Client: Housing Manufacturer ■ Vibration Source: Road Traffic Vibration ■ Preservation Target: Apartment Building (New Construction, 3 Stories) ■ Countermeasure: Plate-type WIB Method (Honeycomb Cell Type) ■ Construction Position: Directly Beneath the Receiving Side *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Some of the residential development plots in Saitama Prefecture face a railway, raising concerns about the impact on the living environment after the construction of the houses. Therefore, the 'WIB method' was implemented directly beneath the houses. In buildings D and E, where the vibration level exceeded 70dB before the measures were taken, the countermeasures were extended on the railway side to enhance the vibration reduction effect. After conducting vibration measurements before and after the measures, the dominant vibration at 10Hz was reduced by 6dB to 14dB (to 1/5 to 1/2 of the original vibration), successfully keeping the vibration level below 60dB. 【Case Summary】 ■ Location: Saitama Prefecture ■ Client: Housing manufacturer ■ Vibration source: Railway vibration ■ Preservation target: Residential buildings along the railway (total of 5 buildings) ■ Countermeasure work: Plate-type WIB (honeycomb cell type) ■ Construction position: Directly beneath the receiving side (partly on the propagation path) *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Some plots of a residential development in Saitama Prefecture face a railway, raising concerns about the impact on the living environment after the construction of the houses. Therefore, the 'WIB method' was implemented directly beneath each of the residential buildings from Building A to Building E. Vibration measurements were conducted before and after the countermeasures. As a result, the dominant vibration at 10Hz was reduced by 14dB (to 1/5 of the original vibration), successfully keeping the vibration level below 60dB. [Case Overview] ■ Construction Location: Saitama Prefecture ■ Client: Housing Manufacturer ■ Vibration Source: Railway Vibration ■ Preservation Target: Residential buildings along the railway (total of 5 buildings) ■ Countermeasure Work: Plate-type WIB method (honeycomb cell type) ■ Construction Position: Directly beneath the receiving side *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In Tokyo, residential buildings are located close to railways that run underground, raising concerns about the impact of railway vibrations on the living environment after the construction of new homes. To address this, the 'WIB method' was implemented directly beneath the residences. Since building support was necessary, support piles were also installed. Vibration measurements were conducted before and after the implementation of the countermeasures, resulting in a reduction of vibrations by 12 to 17 dB (from 1/7 to 1/4), successfully keeping the vibration levels below 50 dB. 【Case Summary】 ■ Location: Tokyo ■ Client: Project owner ■ Vibration source: Railway vibrations ■ Preservation target: Residential buildings along the railway (underground) ■ Countermeasure method: Plate-type WIB (honeycomb cell type) ■ Installation position: Directly beneath the receiving side *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At the model house along the road in Tokyo, large vehicles pass by approximately every five minutes during the day, raising concerns about the impact of traffic vibrations on the living environment. The 'WIB method' was implemented directly beneath the model house, achieving a vibration reduction level of 10-12 dB (about 1/4 to 1/3 of the original vibration). This installation is maintenance-free and semi-permanent, ensuring that even after the model house becomes a regular residence, a comfortable indoor environment free from vibrations will be maintained. 【Case Summary】 ■ Location: Tokyo ■ Client: Mitsui Home Co., Ltd. ■ Vibration Source: Road traffic vibrations ■ Preservation Target: Model house along the road ■ Countermeasure: Plate-type WIB (honeycomb cell type) ■ Installation Position: Directly beneath the receiving side *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the model house along the main road in Chiba Prefecture, there were concerns about the impact of traffic vibrations on the living environment due to the proximity of a heavily trafficked main road after the model house was newly constructed. The 'WIB method' was implemented directly beneath the model house, achieving a vibration reduction level of 12dB (about 1/4 of the original vibration). This model house is planned along a heavily trafficked main road due to its appealing characteristics, but thanks to this construction, the traffic vibrations transmitted from the ground have been reduced, creating an expected quiet indoor environment suitable for the model house. [Case Overview] ■ Construction Location: Chiba Prefecture ■ Client: Tokyo Sekisui Heim Co., Ltd. ■ Vibration Source: Road traffic vibrations ■ Preservation Target: Model house along the main road ■ Countermeasure Work: Plate-type WIB (honeycomb cell type) ■ Construction Position: Directly beneath the receiving side *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The detached houses in Okayama Prefecture are close to a logistics center, and the front road sees a large number of heavy vehicles passing frequently 24 hours a day, raising concerns that these traffic vibrations could affect the living environment of the newly built houses. The 'WIB method' was implemented directly beneath the detached houses. This achieved an average vibration reduction of 5dB (about 55% of the original vibration), resulting in a reduction effect that exceeded expectations within a limited budget. Additionally, the front road is planned to be widened in the future, and its impact has been considered from this stage, ensuring that the ground remains comfortable and safe for living in the future. [Case Overview] ■ Location: Okayama Prefecture ■ Client: Sanyu Soil Engineering Co., Ltd. ■ Vibration Source: Road traffic vibrations ■ Preservation Target: Detached houses near the logistics center ■ Countermeasure: Plate-type WIB method (honeycomb cell type) ■ Installation Position: Directly beneath the receiving side *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

During the construction of the temporary scaffolding for the river gate's sluice work, a vibro hammer was used to install the pile bridge pier. The impact of vibrations on surrounding residential areas and commercial facilities was evaluated through simulation analysis using the two-dimensional finite element method (2DFEM). Based on these results, the client conducted explanations regarding the vibration impact to nearby residents and commercial facility owners before the construction began. Some vibration impacts were observed in residential areas close to the vibration source at the start of pile driving; however, the overall impact on residential and commercial facilities was minimal, with only a very limited range affected. 【Case Summary】 ■ Client: A certain construction consultant ■ Analysis Period: January 2020 ■ Cost: 1.77 million yen (excluding consumption tax, analysis fee for five measurement lines) ■ Vibration Source: Pile driving vibrations from a vibro hammer ■ Analysis Content: Evaluation of vibration impact on residential areas around the sluice gate *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In Shizuoka Prefecture, vibration countermeasures were required for sections where complaints about vibrations had been occurring during road renovation work. As a result, the 'WIB method' was implemented directly beneath the road. Before and after the countermeasures, a driving test was conducted using a 10-ton truck. Vibration responses were measured and compared at the boundary between public and private properties along the route, on the ground within the site, and on the second floor of buildings. It was found that vibrations around the dominant frequency of 6Hz were reduced, achieving an average reduction of 10dB in the horizontal direction and 20dB in the vertical direction. [Case Summary] ■ Construction Location: Shizuoka Prefecture ■ Client: Imamura-gumi Co., Ltd. ■ Vibration Source: Road traffic vibrations ■ Preservation Target: Several houses along the road ■ Countermeasure Method: Plate-type WIB (honeycomb cell type) ■ Construction Position: Directly beneath the vibration source *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In Mie Prefecture, there were concerns that the construction vibrations from the new highway would propagate to nearby public facilities. Therefore, the 'WIB method' was implemented directly beneath the construction vehicle road. After the measures were taken, running tests and impact tests using a backhoe were conducted, and the vibrations at the untreated and treated locations were compared. As a result, it was confirmed that the ground vibrations at the treated locations were approximately 6dB to 7dB lower than those at the untreated locations, reducing the vibrations to less than half. 【Case Overview】 ■ Location: Mie Prefecture ■ Client: Tenox Co., Ltd. ■ Vibration Source: Construction work vibrations ■ Preservation Target: Nearby public facilities ■ Countermeasure Work: Plate-type WIB method (honeycomb cell type) ■ Construction Position: Directly beneath the vibration source *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In Saitama City, Saitama Prefecture, traffic vibrations from the national highway were affecting the living environment along the route, leading to complaints from residents. As a countermeasure, tire shred made of high-damping material was filled within a grid. Renovation work was carried out on the side road that runs between the national highway and the residential area, and the 'WIB method' was implemented directly beneath the road. After conducting vibration measurements before and after the countermeasures, a reduction of 4 to 5 dB in vertical direction was confirmed near the boundary between public and private land. 【Case Summary】 ■ Construction Location: Saitama Prefecture ■ Client: Saitama City ■ Vibration Source: Road traffic vibrations ■ Preservation Target: Several residential buildings along the national highway ■ Countermeasure Work: Wall-type WIB method (grid type) ■ Construction Position: Vibration propagation path *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In Yamanashi Prefecture, with the establishment of new embankment roads, it became necessary to preserve the environment of residential areas along the route after the road opened. Therefore, the "WIB method" was implemented directly beneath the road. A running test using a backhoe was conducted before and after the measures (before road construction). As a result, a reduction of more than 10 dB in both horizontal and vertical directions was confirmed near the public-private boundary, and vibrations were reduced to less than one-third. 【Case Summary】 ■ Construction Location: Yamanashi Prefecture ■ Vibration Source: Road traffic vibrations ■ Preservation Target: Several residential buildings along the road ■ Countermeasure Work: Plate-type WIB (honeycomb cell type) ■ Construction Position: Directly beneath the vibration source *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In Mie Prefecture, there were concerns that construction vibrations from the new highway would propagate to nearby residences. To address this, the 'WIB method' was implemented between the construction area and the homes. After the measures were taken, a running test with a backhoe was conducted, comparing vibrations at the untreated and treated locations. As a result, it was confirmed that the ground vibrations at the treated location were approximately 6dB lower than those at the untreated location, effectively reducing the vibrations by half. 【Case Overview】 ■ Location: Mie Prefecture ■ Client: Tenox Co., Ltd. ■ Vibration Source: Construction work vibrations ■ Protected Target: One nearby residence ■ Countermeasure: Wall-type WIB method (screen type) ■ Installation Position: Vibration propagation path *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In Kanagawa Prefecture, traffic vibrations caused by large vehicles passing through the roads have been affecting the living environment along the routes, leading to complaints from residents. As a response, road renovation work was carried out, and the 'WIB method' was implemented directly beneath the road. Vibration measurements were conducted before and after the countermeasures. When comparing the vibrations at the boundary between public and private properties of four residential buildings along the road before and after the measures, an average reduction of 7 dB and a maximum reduction of 13 dB in the vertical vibration level Lmax was confirmed, resulting in improved livability. [Case Summary] ■ Location: Kanagawa Prefecture ■ Vibration Source: Road traffic vibrations ■ Preservation Target: Several residential buildings along the road ■ Countermeasure Method: Plate-type WIB (honeycomb cell type) ■ Installation Position: Directly beneath the vibration source *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

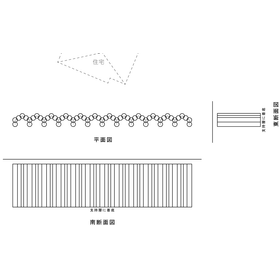

The "WIB method" is a ground vibration mitigation technique that constructs a rigid plate-like or wall-like cellular structure (WIB structure) at the required depth underground using ground improvement piles. This method reduces environmental vibrations from road traffic, railways, construction work, factories, events, and seismic forces on structures during earthquakes. It consists of a replacement soil (vibration isolation layer) that suppresses and blocks the propagation of ground vibration waves, and a cellular structure (damping layer) that absorbs and blocks vibrations. The combined effects of vibration isolation and damping achieve the target vibration reduction. Additionally, it simultaneously exhibits the effects of "vibration mitigation" (improving vibration environments and reducing seismic motion), "liquefaction countermeasures," and "uneven settlement countermeasures," thereby keeping the overall ground improvement costs low. 【Features】 ■ Usable for residential areas, facilities, and roads ■ Reduces seismic forces on structures during earthquakes ■ Enhances the bearing capacity of soft ground, preventing building settlement and liquefaction ■ Keeps overall ground improvement costs low *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Ishiguro Construction in Toyama Prefecture, road traffic vibrations from the surrounding roads of the steel manufacturing facility and operational vibrations from the truck scale within the facility were propagating to the cafeteria building on the same site, causing vibration issues. Therefore, during the reconstruction of the cafeteria building, the 'WIB method' was implemented directly beneath the building. Vibration measurements conducted before and after the countermeasures confirmed that vertical vibrations within the cafeteria building were reduced by 8 to 11 dB. [Case Summary] ■ Location: Toyama Prefecture ■ Client: Ishiguro Construction Co., Ltd. ■ Vibration Sources: Road traffic vibrations, operational vibrations within the facility ■ Protected Target: Cafeteria building within the steel manufacturing facility ■ Countermeasure Work: Plate-type WIB (honeycomb cell type) ■ Installation Position: Directly beneath the receiving side *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Daiho Construction in Fukushima Prefecture, there were concerns about the impact of construction vibrations from the government building on surrounding residences. In response, the 'WIB method' was implemented around the government building. After the measures were taken, vibration measurements were conducted to investigate the impact of construction work on the surrounding area. A comparison of vibration levels between untreated areas and those treated with the WIB method showed a reduction of over 6dB in both horizontal and vertical directions. The vibrations were halved. 【Case Overview】 ■ Location: Fukushima Prefecture ■ Client: Daiho Construction Co., Ltd. ■ Vibration Source: Construction work vibrations ■ Preservation Target: Residences around the government building ■ Countermeasure: Wall-type WIB method (screen type) ■ Installation Position: Vibration propagation path *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At SEIHA located in Chiba Prefecture, vibrations from trains passing near medical facilities were interfering with operations involving precision equipment inside the medical rooms. In response, a 'WIB method' was implemented between the railway and the medical facility. Utilizing existing underground vibration isolation walls, a composite WIB design combining wall-shaped and slab-shaped structures was developed. Based on the micro-vibration tolerance curve for precision equipment, target vibration reduction amounts and target reduction frequency bands were established. After the measures were taken, vibrations in the target reduction frequency band were reduced to less than half, improving the operational environment. 【Case Summary】 ■ Location: Chiba Prefecture ■ Client: SEIHA Co., Ltd. ■ Vibration Source: Railway vibrations ■ Preservation Target: Precision equipment in medical facilities ■ Countermeasure Work: Wall-shaped WIB + Slab-shaped WIB ■ Installation Position: Vibration propagation path *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Mitsui Sumitomo Construction in Ehime Prefecture, vibrations caused by machinery operation within the manufacturing plant were propagating to the adjacent office building (a four-story steel structure), resulting in significant vertical vibrations accompanied by a rumbling phenomenon on the 3rd and 4th floors, necessitating environmental improvements. As a countermeasure, a passage for transport vehicles was constructed between the manufacturing plant and the office building, and the 'WIB method' was implemented directly beneath it. Vibration measurements taken before and after the countermeasures showed a reduction of 10 dB on the 1st floor, while the rumbling phenomenon was eliminated on the 3rd and 4th floors, resulting in a reduction of 15 to 17 dB. Additionally, the vibration level, which had exceeded 70 dB before the countermeasures, dropped to below 60 dB afterward, improving the working environment. 【Case Summary】 ■ Location: Ehime Prefecture ■ Client: Mitsui Sumitomo Construction ■ Vibration Source: Factory vibrations ■ Target for Preservation: Adjacent office building ■ Countermeasure Method: Plate-type WIB (honeycomb cell type) ■ Installation Position: Vibration propagation route *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Mitsui Home in Chiba Prefecture, there were concerns about the impact of vibrations on work within a medical facility being constructed along a road frequently used by large vehicles. To address this, the 'WIB method' was implemented directly beneath the medical facility and the adjacent pharmacy. Using evaluation criteria for micro-vibrations aimed at precision equipment, a vibration reduction target was set. As a result, dominant vibrations in the 10-20Hz range were reduced by 6-10dB, achieving the vibration reduction target. [Case Summary] - Construction Location: Chiba Prefecture - Client: Mitsui Home Co., Ltd. - Vibration Source: Road traffic vibrations - Preservation Target: Medical facility - Countermeasure: Plate-type WIB method (honeycomb cell type) - Construction Position: Directly beneath the receiving side *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The construction site for a factory handling precision equipment in Kyoto Prefecture faces a road, raising concerns about the impact of vibrations from road traffic on operations and equipment within the factory. To improve the road traffic vibrations at the factory site to a vibration environment suitable for the normal operation of precision equipment, measures targeting micro-vibrations were implemented. Vibration tolerance limits (VC ranks) were set according to the types of precision equipment to be installed in the factory, and performance design was carried out to reduce vibrations in the dominant frequency range to target values. After the measures were implemented, vibrations within the factory were reduced to 1/4 to 1/3, achieving the vibration reduction goals. 【Case Overview】 ■ Location: Kyoto Prefecture ■ Client: Tsumiya Metal Co., Ltd. ■ Contractor: Yu Architectural Design Co., Ltd. ■ Vibration Source: Road traffic vibrations ■ Preservation Target: Precision machinery factory ■ Countermeasure: Plate-type WIB (honeycomb cell type) ■ Installation Position: Directly beneath the receiving side *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Maetani Architectural Office located in Osaka Prefecture, vibrations from demolition and transportation activities of a nearby metal recycling company were affecting the operation of precision machining equipment. Therefore, during the expansion of the factory, the 'WIB method' was adopted as a vibration countermeasure, and a design targeting micro-vibrations was implemented. We investigated the impact of vibrations on the existing factory's precision machining equipment and based on this data, designed and constructed directly beneath the new factory. As a result, resonant vibrations in the range of 10 to 16 Hz were reduced by 6 to 14 dB (to 1/5 to 1/2 of the original vibrations), creating an environment suitable for the normal operation of precision machining equipment. 【Case Overview】 ■ Construction Location: Osaka Prefecture ■ Client: Maetani Architectural Office Co., Ltd. ■ Vibration Source: Demolition work vibrations ■ Preservation Target: Precision machining factory ■ Countermeasure Method: Plate-type WIB method (honeycomb cell type) ■ Construction Position: Directly beneath the receiving side *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At a certain company located in the Kinki region, there were concerns about the impact of vibrations from the internal roads on the new manufacturing plant being established. Since vibration-sensitive equipment is scheduled to operate within the factory, a quiet environment is required. Therefore, the "WIB method" was adopted as a vibration countermeasure, and a design was developed specifically targeting micro-vibrations. After the countermeasures were implemented, the perceived vibrations were reduced to 1/7 to 1/5 of the previous levels. The transmission of vibrations to the manufacturing plant was mitigated, creating an environment where the vibration-sensitive equipment could operate normally. 【Case Summary】 ■ Location: Kinki ■ Client: Certain Company ■ Vibration Source: Vibrations from the internal factory roads ■ Preservation Target: Newly established manufacturing plant ■ Countermeasure Method: Plate-type WIB (honeycomb cell type) ■ Installation Position: Directly beneath the receiving side *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company measures environmental vibrations such as road traffic vibrations, railway vibrations, factory vibrations, construction work vibrations, and event vibrations, and conducts analysis and evaluation according to the purpose. In "Environmental Impact Assessment," we carry out vibration measurements of the target property, identify the vibration sources, and evaluate the impact of vibrations. We assess the vibration effects on the target property based on evaluation guidelines tailored to the purpose. If it is determined that vibrations from current or future new sources exceed permissible limits in the target property or region, we obtain the necessary information for vibration reduction design from the measurement data and design countermeasures. Additionally, we conduct vibration measurements after the countermeasures are implemented to confirm their effectiveness. 【Measuring Equipment】 <Acceleration Pickups> ■ NP-7310 ■ VSE-15A ■ VSE-15D *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company conducts predictive analysis of ground vibrations caused by moving vibration sources such as road traffic and railways, as well as fixed vibration sources like factory machinery and concrete pouring machines, through computer simulation. In the simulation analysis, we create a ground model that reflects local ground information and input excitation forces that reflect local vibration data to output response values. Before constructing structures that are vibration sources (such as roads, railways, and factories) or buildings that are vibration receivers (such as residences, offices, and public facilities), we can predict the impact of vibrations on the buildings after construction. [Information Required for Vibration Analysis via Computer Simulation] ■ Ground information (geological data from boring penetration tests) ■ Vibration information (vibration data from vibration measurements) *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Differential settlement refers to the uneven application of the building's load on the ground, causing the building to tilt. When differential settlement occurs, it can lead to various issues in daily life, such as doors and windows not closing properly and health problems. By constructing a WIB structure within the ground, the rigidity of the WIB structure distributes the load into the ground, resulting in a structural form that increases the bearing capacity against the building load beyond the strength of the original ground at ultimate bearing capacity. Since the WIB structure is built with a planar spread, it can be designed to evenly distribute the loads from buildings and other structures. As a result, it can suppress differential settlement of the ground and improve the safety of the building. 【Features】 ■ Strengthening the ground serves as a foothold for suppressing differential settlement. ■ Designed to evenly distribute the loads from buildings and other structures. ■ Can suppress differential settlement of the ground and improve building safety. *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Liquefaction Countermeasure WIB Method" protects buildings from damage caused by earthquakes and liquefaction. The basic structure consists of replacement soil that acts as a seismic isolation layer, ground improvement piles that function as a damping layer, and support ground improvement piles that support the building foundation. The ground improvement piles in the damping layer are constructed in a cellular form, creating a strong and stable composite ground (non-liquefaction layer). Additionally, by increasing resistance through the combination of pile foundations and the WIB method, it is possible to reduce the number of piles or lower the grade of the piles, thereby rationalizing the design and contributing to cost reduction. 【Features】 ■ Ground improvement piles in the damping layer are constructed in a cellular form ■ Creates a strong and stable composite ground (non-liquefaction layer) ■ During an earthquake, the cellular ground improvement piles restrain the soil inside the cells ■ Suppresses ground distortion and reduces seismic motion ■ Since liquefaction does not occur inside the cells, it blocks the propagation of liquefied mud water below, preventing surface liquefaction *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Various vibrations from road traffic, railways, factories, and construction work exist around us. These vibrations are often perceived as unpleasant and can negatively impact daily life. The "Vibration Countermeasure WIB Method" addresses these vibration issues and creates a comfortable living environment. Additionally, the installation location and shape can be selected according to each property. 【Summary of Achievements (Partial)】 ■ Vibration Source: Road traffic vibration ■ Installation Location: Directly beneath the vibration source ■ WIB Method Type: Plate-type WIB Method (Honeycomb cell type) ■ Issue: Vibrations from large vehicles passing on the road propagate to nearby residences, leading to vibration complaints ■ Response: Road improvement work was carried out, and a honeycomb cell-type plate WIB Method was installed directly beneath the road *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

E&D Tech Design Co., Ltd.'s "WIB Method" is an improved ground method that reduces environmental vibrations from traffic, factories, and construction, as well as seismic shaking, while addressing liquefaction and enhancing and stabilizing the bearing capacity of weak ground. By using a rigid cell-type plate or wall structure, it simultaneously achieves liquefaction prevention and differential settlement prevention, making it a cost-effective method overall. Additionally, it can also address micro-vibrations that interfere with the operation of precision machinery and medical devices in high-tech industries. 【Features】 ■ Liquefaction prevention through strain suppression of the ground using a cell-form structure ■ Differential settlement prevention through improved horizontal bearing capacity of the ground using a plate structure ■ Vibration reduction value prediction and design based on ground surveys, achieving set targets ■ Recipient of the Minister of Education, Culture, Sports, Science and Technology Award for Scientific and Technological Achievement in 2011 ■ Capable of addressing micro-vibrations that affect medical devices *For more details, please refer to the catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration