1~9 item / All 9 items

Displayed results

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us Online1~9 item / All 9 items

We would like to introduce our construction method, the "Enclosure Column Ramen Wooden Structure." A wooden framework that combines construction speed, strength, and durability. Large open spaces that do not require shear walls can be realized with this structure. Please consider adopting the various methods that utilize the "Enclosure Column" in complementary ways: "Enclosure Column" + traditional framing method, "Enclosure Column" + board warehouse method, "Enclosure Column" + truss construction, and "Enclosure Column" + CLT panels. 【Compatible Construction Methods】 ■ Traditional Framing ■ Board Warehouse ■ Truss ■ CLT *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a case study of the "encased column frame wooden structure" used at Hashima Orthopedic and Dermatology Clinic. Wood is gentle on people, providing warmth, healing, mental stability, and refreshing effects. This structure was adopted with the intention of achieving these benefits in rehabilitation treatment through the space. Initially, the plan was for a steel structure with only the interior designed in wood, but the encased column frame structure allows for a large open space that matches the rehabilitation room and results in a sustainable building. 【Case Overview】 ■ Main Structure - 2nd Floor: Steel Structure - 1st Floor: Steel Structure + Wooden Structure (Encased Column Frame Wooden Structure) ■ Fire Resistance Requirements: Fireproof Structure ■ Total Floor Area: 499.63 m² ■ Main Wood Species Used: Hinoki (Japanese Cypress) and Sugi (Japanese Cedar) *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce an example of the "enclosed column frame wooden structure" adopted on the second floor of the LINEindustry Prefectural Timber Utilization New Office. This structure effectively utilizes local timber (cypress and cedar) in a natural and stress-free manner, and since it does not require shear walls, it allows for three sides to be covered in glass. Additionally, as it consists of a collection of four 120mm square timber pieces, the line of sight passes through the middle of the columns, enabling the construction of robust columns without a bulky appearance. 【Case Overview】 ■ Main Structure - 2nd Floor: Wooden (enclosed column frame wooden structure) - 1st Floor: Reinforced concrete ■ Fire resistance and other requirements: Other buildings ■ Total floor area: 245.26m² ■ Main tree species used: Cypress and cedar *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

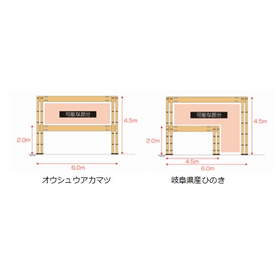

We will introduce test cases for the pursuit and development of robustness in our "Column Frame Wooden Structure." We conducted in-plane shear tests on three specimens each for the maximum span (6.0m) under load and the minimum span (4.5m) without load. Additionally, we confirmed the failure mode under 45-degree loading for the two-directional frame. 【Case Overview】 ■ Span 6m and 4.5m, loaded and unloaded - Columns: 120×120mm, Hinoki structural lumber, E110 or higher - Beams: 120×450mm, Hinoki symmetrical graded laminated timber, E105-F300 ■ Two-directional frame - Comparison with in-plane shear test results of the planar frame - Test specimen dimensions: 6000mm×6000mm×2825mm *For more details, please refer to the related links or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce the results of research and development related to the "Encased Column Frame Wooden Structure" that we handle. The moisture content SD of the Oushu Red Pine and the Hinoki from Gifu Prefecture in the frame type is below 20%, and the Young's modulus E is above 110. It is possible to arrange them in "lines" and "planes." 【2-Way Frame】 ■ Size of 6.0m in width and height of 3.0m with moisture content SD below 20% and Young's modulus E above 110 ■ Arranged in "lines" ■ Arranged in "planes" ■ Arranged "freely" *For more details, please refer to the related links or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce the features of the "Enclosure Column Frame Wooden Structure" that we handle. The labor-intensive "enclosure column structure" is precisely manufactured in the factory, allowing for a streamlined assembly process on-site, similar to steel frame construction, where only the beam placement is required. Additionally, since both the columns and beams are interconnected, it has the characteristic of resisting bending moments and being difficult to rotate. 【Other Features】 ■ Ingeniously designed hardware enhances the latent strength of the wood ■ Weight ratio of wood to steel is 1:20 ■ Easy assembly ■ Easy crane handling and transportation ■ Constructed with sawn timber columns *For more details, please refer to the related links or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We will introduce the assembly and construction process of the "Enclosure Column Frame Wooden Structure" that we handle. The enclosure column is completed by pressing a φ16 pin into the column-beam joint of the hydraulic insertion machine. The construction process involves suspending the enclosure column, then joining it at the joint section with a bracket, similar to the appearance of a steel column, and wrapping it with an L-shaped splice sheet, securing it with screws. 【Assembly Process of the Enclosure Column】 1. Four 120mm square column materials 2. Assembled with dedicated hardware 3. Bolts are tightened 4. Completed *For more details, please refer to the related links or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Enclosure Column Frame Structure" is a type of wooden frame structure made from "structural timber" and "specialized hardware." It consists of four general-purpose cedar lumber pieces secured with specialized hardware to form a robust "enclosure column" and rigid beams, creating a wooden frame that does not rely on shear walls. Continuous large openings and spacious areas enrich human activities. 【Features】 ■ Kind to people (sensory effects) → Aroma, warmth, texture ■ Insulating effect of wood itself → About 20 times more effective than steel frames ■ Excellent workability ■ Superior processability ■ Reduction in insulation construction costs / Lower material costs and foundation construction costs *For more details, please refer to the related links or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

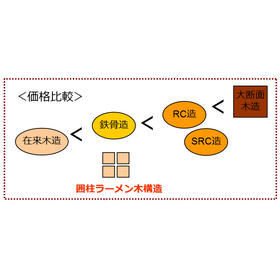

The "Enclosure Column Frame Wooden Structure" is a realization of a "complete wooden frame" through the collaboration of "wood" and "steel." If each collaborating element can draw out 100% of its strength, it can serve as the "skeleton" for mid-sized low-rise buildings, possessing the strength to replace steel structures. The "Enclosure Column Frame Wooden Structure" can create a unique wooden space that has no precedent until now. 【Features】 - No need for shear walls - Collaboration of wood and steel - Structural body with strength to replace steel structures - Cost reduction compared to steel structures - Becomes the "skeleton" for mid-sized low-rise buildings For more details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration