1~19 item / All 19 items

Displayed results

Filter by category

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us Online1~19 item / All 19 items

Filter by category

Advantages of adopting the Neplus method at the proximity of structures! 1. It can avoid interference with the excavation of the structure's foundation. 2. It can be easily constructed even if there are block walls with shallow embedment nearby. 3. It ensures the stability of existing structures. 4. It can be safely constructed even if there are buried utilities such as gas pipes, water pipes, and optical cables nearby.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

On the school route, ensuring the safety of students is the top priority. The deterioration and damage of drainage ditches can increase the risk of falls and vehicle accidents. In particular, traffic regulations during school hours can place a significant burden on parents and nearby residents, so we want to avoid them as much as possible. The Neplus method allows for immediate traffic reopening, ensuring the safety of school routes while minimizing the impact on traffic. 【Usage Scenarios】 - Renovation of drainage ditches on school routes - Repair of ditches between sidewalks and roadways - Repair of ditches around schools - Construction of new sidewalks utilizing waterway beds 【Benefits of Implementation】 - Ensures safe passage for students - Minimizes the impact of traffic regulations - Reduces accident risk through early ditch repairs - Cuts construction costs (especially effective for large waterways)

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the construction industry, the aging of drainage ditches poses challenges that not only compromise road safety and aesthetics but also lead to traffic restrictions and increased costs due to repair work. Especially in modern times, where the longevity of infrastructure is required, proper maintenance and management of drainage ditches is a critical issue. The Neplus method allows for the renovation of only the upper part of damaged drainage ditches, eliminating the need for excavation and enabling construction while avoiding structures and underground installations. This minimizes the impact on traffic while achieving the longevity of drainage ditches. 【Application Scenarios】 - Renovation of drainage ditches in various locations such as roads, highways, airport and port facilities, railway facilities, factories, and stores - Renovation of drainage ditches in areas where traffic regulation is difficult - Construction in locations close to underground installations or structures - Addressing the need for height adjustments of drainage ditches due to road improvements - Resolving construction difficulties caused by the depth of free-slope drainage ditches 【Benefits of Implementation】 - Shortened construction period due to immediate traffic reopening - Cost reduction due to no excavation required - Effective use of resources through the reuse of existing covers - Improved durability with steel frames - Ability to meet a wide range of needs with diverse product variations

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The aging of drainage ditches is a significant issue in improving road safety. Damaged ditches can lead to accidents involving pedestrians and vehicles, undermining the overall safety of the road. Additionally, repairing ditches incurs time and economic losses due to traffic regulations. The Neplus method was developed to address these challenges. 【Usage Scenarios】 - Roads with heavy traffic - Sidewalks with many pedestrians - Repair of aging drainage ditches - Urgent repairs of drainage ditches 【Effects of Implementation】 - Minimization of traffic impact through same-day reopening - Reduction of accident risk through upgrades to safer drainage ditches - Potential cost savings by reusing existing covers

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

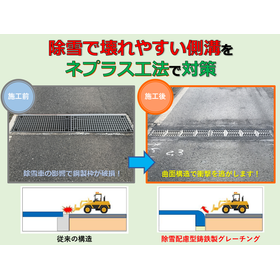

In local governments, the maintenance of roads faces significant challenges due to damage to grates caused by snow removal. Damage to grates not only increases the frequency of repair work and strains budgets but can also obstruct traffic. Our snow-removal-friendly cast iron grates help prevent damage from snowplows and contribute to solving challenges in the maintenance of ditches. 【Usage Scenarios】 - Cross ditches and entrance ditches on snow removal routes - Areas where a step difference between the grate and the pavement is likely to occur (areas prone to ruts) - Areas where corrosion of grates due to de-icing agents is severe 【Benefits of Introduction】 - Prevents damage from snowplow blades - Significantly reduces restriction time with same-day traffic reopening - The cast iron integrated structure makes the grate body resistant to deformation, allowing for long-term use - The cast iron integrated structure improves corrosion resistance and durability

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In ensuring safety on highways, snow removal operations during snowfall are essential. However, there are frequent cases where the snow plow of snow removal vehicles gets caught on grates, causing damage. The damage to the grates not only threatens the safety of passing vehicles but also leads to traffic restrictions due to repair work, creating further risks. Our snow removal-friendly cast iron grates are designed to be less affected by snow removal vehicles, even with some height differences. This reduces the risk of grate damage and ensures safe passage on highways. 【Usage Scenarios】 - Snow removal routes on highways - Areas where height differences between grates and pavement are likely to occur - Areas with severe corrosion of grates due to de-icing agents 【Benefits of Implementation】 - Prevents damage from snow plows of snow removal vehicles - Significantly reduces restriction time due to immediate traffic reopening - The cast iron integrated structure makes the grates less prone to deformation, allowing for long-term use - The cast iron integrated structure improves corrosion resistance and durability

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In areas with snowfall, there are many instances of grating damage due to snow removal. Particularly, when there is a step between the grating and the pavement surface, the risk of damage is high, and frequent repair work is currently being carried out. The Neplus method offers grating that is less affected by snowplows even with some step differences. The snow removal-friendly grating features a cast iron integrated structure that is corrosion-resistant and durable, significantly contributing to the reduction of lifecycle costs. 【Usage Scenarios】 - Cross-drainage ditches and access ditches on snow removal routes - Locations where steps between the grating and pavement surface are likely to occur (areas prone to ruts) - Areas where grating corrosion due to de-icing agents is severe 【Benefits of Implementation】 - Prevents damage from snowplow blades - Significantly reduces restriction time by allowing immediate traffic reopening - The cast iron integrated structure makes the grating body less prone to deformation, allowing for long-term use - The cast iron integrated structure improves corrosion resistance and durability

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the maintenance and management of ditches by local governments, consideration for surrounding residents and private property, as well as the impact of traffic congestion due to traffic regulations, are significant challenges. In particular, the renovation of aging ditches tends to lead to prolonged traffic regulations and increased costs due to excavation work. The Neplus method was developed to address these challenges. 【Usage Scenarios】 - Renovation of ditches in areas where traffic regulation is difficult, such as road crossings or in front of stores - Construction in locations close to underground installations or structures - Responding to needs for height adjustments of ditches (raising or lowering) due to road improvements - Resolving difficulties in construction caused by the depth of free-slope ditches 【Effects of Implementation】 - Shortening of traffic regulation periods due to immediate reopening of roads - No excavation required, avoiding impact on underground installations and private property - Potential cost savings through the reuse of existing covers - Significant reduction in construction time

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Due to the height difference between the road and the drainage ditch, many drainage covers have been damaged during winter snow removal operations. In particular, the damage to grates can lead to tire punctures, which is very dangerous. To prevent such damage, some areas in snow-prone regions install drainage covers lower than the road surface. However, during non-snow periods, the height difference can hinder bicycle passage and lead to accidents, as well as cause noise and vibration when vehicles pass. By using the Neplus method for construction, the work can be completed in a short period.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In conventional rolled gutter connection catch basins, the accumulation of fallen leaves obstructs the flow of water, making drainage impossible. The "Kansuke" rolled gutter connection catch basin directs drainage from the crown plate of the three-dimensional part, preventing surface flooding. By using the Neplus method for installation, replacement work can also be easily carried out.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Neplus Method's advantages" introduce a new approach that completely replaces the traditional method of replacing entire drainage ditches, by cutting and repairing only the damaged upper part of the ditch, showcasing the benefits of this rational method. The "Neplus Method" not only shortens construction time compared to conventional methods but also reduces costs and minimizes waste materials. 【Features】 ■ Construction waste reduced by 80% compared to conventional methods ■ Excavation residual soil reduced by 100% compared to conventional methods ■ Can be implemented even when structures are close together ■ Immediate traffic reopening for resident peace of mind ■ Reduction of social losses due to traffic restrictions ■ No need for temporary drainage channels, reducing expenses ■ Capable of construction under various conditions 【Contents】 ■ What is the Neplus Method? ■ Features of the Neplus Method ■ Construction methods ■ Case studies * Registration period for NETIS ended in March 2017 (Registration number HR-060021) * For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Nepuras Method's advantages" introduce a new approach that revolutionizes the traditional method of completely replacing all drainage ditches by only cutting and repairing the damaged upper part of the ditch, highlighting the benefits of this rational technique. The "Nepuras Method" not only shortens construction time compared to conventional methods but also reduces costs and minimizes waste materials. 【7 Advantages】 ■ Construction waste reduced by 80% compared to traditional methods ■ Excavation residual soil reduced by 100% compared to traditional methods ■ Can be implemented even when structures are close together ■ Immediate traffic reopening ensures resident peace of mind ■ Reduces social losses due to traffic restrictions ■ No need for temporary drainage ditches, saving costs ■ Capable of handling construction under various conditions *NETIS Ministry of Land, Infrastructure, Transport and Tourism New Technology Information System Registration Number HR-060021 *For more details, please refer to the PDF document or feel free to contact us. *Construction method videos are currently being showcased at the link below!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the "Neplus Method," the development of a side cutting machine allows for the cutting and repair of only the upper part of the drainage ditch, achieving construction times that are one-third to one-fourth of traditional methods. Additionally, if the length of the repair area is around 10 meters, the work can be completed in one day, allowing for immediate lifting of traffic restrictions and minimizing the time vehicles are blocked. There are two main types of repair products: cross-sectional type and longitudinal type, which are used according to the conditions of the construction site. The Neplus Method demonstrates its effectiveness along drainage ditches that run across roads and structures such as block walls, and it is also compatible with irrigation channels, snow-melting ditches, and catch basins. 【Construction Method】 1. Installation of running rails 2. Cutting of the drainage ditch 3. Removal of concrete 4. Drilling of bolt holes 5. Injection of special adhesive 6. Installation of the upper repair product for the ditch 7. Filling with concrete 8. Tamping of pavement materials *For more details, please refer to the PDF materials or feel free to contact us. *The construction method video is currently available at the link below!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The Neplus construction method "Slit Type" is a recommended longitudinal type for roadside ditches and similar applications. It can accommodate various types of roadside ditches, not just flat roads. A hole of Φ20×20 mm is drilled, and approximately 20 mm of elevation is added, securing it with anti-shift rebar and filling. The inspection port is constructed using an embedded M20 adjustment nut. It is also possible to carry out construction even if a block excavation is close to the side ditch. *For more details, please contact us or download the PDF materials for review. *Videos are also currently available at the link below!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The Neplus method "Circular Drainage Ditch Compatible Type" is a recommended product for efficient drainage in circular ditches. It can be used in circular waterways with continuous drainage ditches, such as tunnels, and you can choose from two types: longitudinal and transverse, so please select the specifications according to the site conditions. An epoxy adhesive suitable for metal is used for filling. *For more details, please contact us or download the PDF materials to view.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The Nepuras method "Cross Type" is a product that allows for smooth drainage into ditches and other areas, featuring embedded parts such as grating. The Nepuras method "Angle Type" allows for the selection of materials based on site conditions and load requirements. By checking the size of the side ditches and the construction locations for the Cross Type, Longitudinal Type, grating, concrete covers, etc., a balanced Nepuras method is completed, taking into account economic efficiency, strength, durability, and workability. *For more details, please contact us or download the PDF materials to view.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The Neplus method "Soundproof Type" is suitable for locations where stores or residences are adjacent to drainage ditches and excavation cannot be performed, or where excavation cannot be done at parking lot entrances or retaining walls. By using the soundproof type, noise such as rattling sounds can be prevented. In conventional methods, the work takes 4 to 5 days, but the Neplus method can be completed in one day, making it safe to use even in stores, residences, and busy parking lots. 【Comparison with Conventional Methods】 ● Conventional Method Survey → Temporary Closure → Pavement Slab Crushing → Mechanical Excavation → Foundation Work → Drainage Ditch Installation → Pavement Restoration → Completion - Days: 4-5 days - Asphalt Waste: 0.30 m² - Excavated Soil Volume: 30.5 m² - Concrete Waste: 0.87 m² ● Neplus Method Survey → Cutting → Installation of Renovation Products → Backfilling Material → Installation of Cover Plate → Completion - Days: 1 day - Asphalt Waste: 0 m² - Excavated Soil Volume: 0 m² - Concrete Waste: 0.17 m² *For more details, please contact us or download the PDF materials for review.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

With the Neplus method 'buried type', even in large waterways, design blocks, and painted sidewalks, everything except the grating can be buried, ensuring proper drainage without interfering with the design, allowing for paving. In the conventional method of completely replacing the gutters, there is waste involved as the surrounding area needs to be excavated, the existing gutters removed, and new gutters installed. The Neplus method uses a lateral cutting machine, allowing for paving in a short period. *For more details, please contact us or download the PDF materials to view.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"Kansuke" is a product that combines L-shaped drainage channels for fallen leaves and flood prevention with universal design grating for bicycles. It can also be installed using the Neplus method for repairing roadside ditches. Even if clogging occurs on the grating, drainage is maintained through the drainage holes on the vertical sections. **Features of Kansuke** - **Enhanced drainage performance at the L-shaped channel curb!** To address flooding caused by sudden heavy rain or concentrated downpours, drainage holes have been added to the curb section to improve drainage performance. This prevents flooding even when there are obstacles like fallen leaves or newspapers and magazines that could hinder drainage, thanks to stable drainage performance. - **Compatible with the Neplus method (drain cover repair)** The Neplus method, which has brought innovation to roadside ditch repair work, allows for the replacement of only the damaged parts, shortening construction time, reducing waste, and requiring fewer materials, making it a groundbreaking method. - **Supports safe cycling** By changing the shape of the grating to a triangular pitch, it prevents wheels from getting stuck or falling in. Additionally, the incorporation of anti-slip protrusions in the components has improved slip resistance. *For more details, please contact us or download the PDF materials for further information.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration