Short curing time and high strength achieved! Includes typical products from various manufacturers and methods of placement.

Explanation of the shape management items in the expansion device construction, such as installation height and surface irregularities!

Be cautious with narrow bridges! An explanation of the purpose of secondary water-stopping materials and an introduction to products from various companies.

The water resistance greatly varies depending on the ground cover! A detailed explanation of the shapes and types of ground cover!

Introducing the types of expansion devices and explaining their features and benefits!

Explaining the structure of bridges and the names and roles of each component! Introducing types of bridges categorized by structure and materials.

Automation of porcelain mortar (mortar) and porcelain pestle (pestle). Ideal for a wide range of applications including stirring, grinding, kneading, and mixing in food, pharmaceuticals, chemicals, and electronic materials fields.

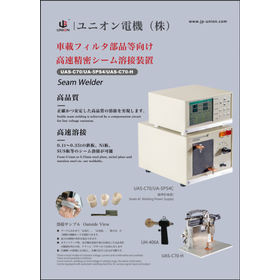

Single-phase AC seam welding power supply, resistance soldering machine, electric soldering machine, spot soldering machine, and can also be repurposed as a spot welding machine.

Ideal for fusion welding and spot welding of motor products. We are a manufacturer of precision resistance welding machines; leave welding processing and sample welding to us.

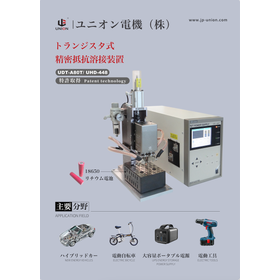

High-quality and stable welding of battery packs. Used for battery welding in EV vehicles. Compatible from power supply to automatic machines.

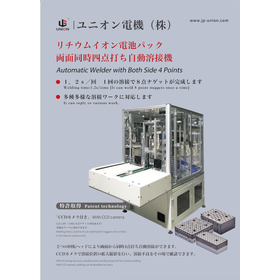

The fastest and highest quality welding automation machine for secondary batteries. Equipped with a transistor-type welding automation machine and a 4-point welding head. Capable of reducing welding time.

It is a brazing electrode made of pure tungsten and chromium copper. It is very affordably priced.

Detailed information on "the purpose of preliminary compression," "calculation methods," and "unnecessary cases" is provided!

Introducing measures for work from below and splash prevention from the sides, tailored to the conditions of the site and construction!

Explanation of the six main changes! Publication on the revised method of selection calculations in the Road Bridge Design Guidelines.

Here are 10 key points for replacing expansion devices! We encourage those in design and estimation roles to take a look.

13 Selected Expansion Device Manufacturers! Let's use the design criteria to find the best company from the list of expansion device manufacturers!

Introducing the features and differences of bridge expansion devices, including explanations of expansion devices by component and the three classifications of expansion devices!

Select the appropriate product based on the "expansion amount" and the "standard clearance amount" in the drawing! Introducing the method for selecting expansion devices.

A clear explanation of the damage caused by noise and the causes of noise generation! We will also introduce inspection methods.

Secondary water stop materials for secondary water stopping! An explanation of the purpose and an introduction to products from various manufacturers.

We are explaining what role the expansion and contraction device plays!

Introducing what a PC bridge is, including its benefits! Also explaining the differences from steel bridges.

Explanation of the main types of bridge foundations: shallow foundations, pile foundations, and caisson foundations.

Full of information such as international standards to refer to, methods for risk assessment, oil and pneumatic risk reduction measures for various applications, and equipment selection flowcharts.

Full of information such as international standards, methods and precautions for risk assessment, examples of risks associated with hydraulic and pneumatic equipment, and a selection flowchart for hydraulic and pneumatic equipment.

We will introduce a new risk assessment method for conducting risk assessments on machines/equipment that use oil pneumatic energy!

Ideal for tabletop experiments. It employs a mechanism that forcibly rotates the pestle with a motor, providing higher grinding performance. Suitable for the dispersion, mixing, crushing, and disintegration of hard materials.

The pestle rotation part rises and falls, making it easier to exchange the mortar and pestle (pestle), remove the ground material after grinding, and clean the machine. A tabletop machine for simultaneous stirring and dispersion processing.

The electrode materials for all-solid-state batteries, such as lithium, sulfur, silicon, and carbon (Ketjenblack), are suitable for processing and kneading the electrolytes of ion batteries.

Stirring, grinding, crushing, and homogenizing while dispersing liquids, slurries, pastes, powders, and cakes. Large-capacity type suitable for mass production.

- It is possible to grind a few grams of materials. - Due to its compact size, grinding in an argon gas atmosphere inside a glove box is also possible.

Can grind even 0.5g of material. Can be used in glove boxes and draft chambers due to its ultra-compact size. Equipped with a timer and speed adjustment function.

Introducing key points for cost-reduction design and manufacturing of large precision structures, along with illustrations!