Carbon fiber and aramid fiber sheet repair and reinforcement method construction - Reliable reinforcement construction

Toray Construction Materials Co., Ltd. and Maeda Kosen Co., Ltd.

We support various continuous fiber sheet reinforcement methods and protect asset value with reliable technology, primarily in the Kanto region.

Using sheets of carbon fibers or aramid fibers, which are lightweight, high-strength, and excellent in corrosion resistance, arranged in one direction or two directions, we reinforce structures by impregnating them with a special epoxy resin and adhering them to the surfaces of concrete or wood. This method is highly effective for reinforcing areas lacking rebar, improving bending and shear strength, suppressing cracks, and enhancing fatigue durability. It adds almost no weight and does not impose a burden on existing structures. It is applicable not only to wooden houses but also to reinforced concrete and steel structures. The Wood Preservation Center has numerous construction achievements, mainly in the Kanto region, and provides consistent support from suitable reinforcement design to construction with reliable technology. If you are considering improving the performance of your building or maintaining its asset value, please feel free to consult us.

Inquire About This Product

basic information

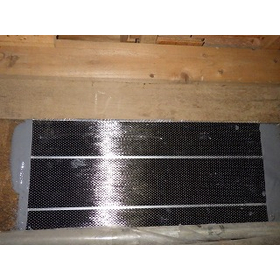

【Toreka Cross Representative Product Number Specifications List】 UT70-20G: For bending and shear reinforcement. Tensile strength 3,400 MPa, Young's modulus 230 GPa, unit weight 200 g/m², thickness approximately 0.11 mm, standard widths 25, 33, 50 cm. UT70-30G: Tensile strength 3,400 MPa, Young's modulus 230 GPa, unit weight 300 g/m², thickness approximately 0.17 mm, widths 25, 33, 50 cm. UT70-40G: Tensile strength 3,400 MPa, Young's modulus 230 GPa, unit weight 400 g/m², thickness approximately 0.22 mm, widths 25, 33, 50 cm. UT70-60G: Tensile strength 3,400 MPa, Young's modulus 230 GPa, unit weight 600 g/m², thickness approximately 0.33 mm, width 50 cm. UT46-30G: For high-elasticity reinforcement. Tensile strength 2,500 MPa, Young's modulus 440 GPa, unit weight 300 g/m², thickness approximately 0.16 mm, width 25 cm.

Price information

Foundation reinforcement work using carbon fiber and aramid fiber sheets generally costs around 25,000 yen per meter. Most installations occur around the foundation perimeter, and the price can fluctuate up to about 30,000 yen depending on the reinforcement width, number of layers, and the extent of substrate repairs. For larger areas or multi-layer installations, the unit price per square meter typically ranges from 40,000 to 60,000 yen. Prices vary based on the type of sheet used (such as UT70 or UT46) and construction conditions (such as scaffolding and crack repairs). After an investigation, we will provide an accurate quantity and situation assessment, and we will propose details in our estimate, so please feel free to consult us.

Price range

P4

Delivery Time

Applications/Examples of results

At the Wood Preservation Center, we primarily use carbon fiber sheets (Trekacross) for reinforcement in residential foundations and columns and beams of reinforced concrete (RC) buildings, with a wealth of experience mainly in the Kanto region. We handle not only foundation crack repairs and seismic reinforcements but also improvements in the load-bearing capacity of RC structures. Additionally, during renovations, we address repairs and reinforcements of decayed areas using wood epoxy for timber. We also perform carbon fiber sheet reinforcements on wooden beams, girders, and foundations, which are difficult for other companies to undertake, allowing us to flexibly respond to a wide range of structures. We carefully investigate the condition of each building and propose suitable reinforcement plans. To connect your valuable assets to the future, we provide solid support with reliable technology and attentive service. Please feel free to consult us about any small matters.

Detailed information

-

In wooden structures, there is a method that uses aramid fiber sheets to reinforce load-bearing members such as beams and girders. By adhering lightweight and highly ductile aramid fibers to wood with a specialized resin, this method enhances bending and shear strength, compensating for deficiencies in strength due to earthquakes and aging deterioration. Since there is no concern about rust and it easily accommodates the movement of wood, it can also address the unique drying shrinkage of timber. This method allows for reinforcement without replacing existing beams or foundations, resulting in a shorter construction period, making it suitable for those looking to enhance seismic resistance while keeping costs down.

-

In renovations, it often becomes necessary to proceed with the work while preserving existing structural materials. Therefore, it is important to find methods that can reinforce strength while utilizing the existing wood, rather than replacing all damaged parts. Our company performs reinforcement and repair using aramid fiber sheets and epoxy for wooden components on wooden beams, girders, and foundations. This allows us to effectively reinforce areas weakened by termite damage or decay, restoring them to a safe and usable condition. By making use of existing wood, we can shorten construction time and reduce costs. To protect the important structure of your home without waste and ensure its longevity, please feel free to consult with us. We will carefully diagnose the condition and propose suitable reinforcement methods.

-

To ensure the longevity of concrete structures, it is very important to prevent the internal rebar from rusting. Rebar is a crucial component that bears the tensile strength of concrete, but when rust progresses due to cracking, carbonation, or the intrusion of salt, it expands and can crack the concrete, leading to delamination or spalling. This is a cause of reduced structural strength and can lead to extensive repairs. Therefore, during repair work, it is essential to properly expose and clean the rebar, remove any rust, and carefully apply a rust-inhibiting primer. Neglecting this treatment can lead to the reoccurrence of rust, potentially shortening the lifespan of the repair. The rust-inhibiting primer stabilizes the surface of the rebar, making it less prone to rusting again, while also enhancing adhesion to mortar and resin. At the Wood Preservation Center, we thoroughly implement this rust prevention treatment to protect the rebar over the long term, thereby significantly extending the lifespan of your valuable building. You can trust us to handle it with confidence.

-

Reinforcement with carbon fiber and aramid fiber sheets requires very important crack repairs before reinforcement. Simply covering the surface with a sealant does not completely prevent the intrusion of water and air into the interior, leading to the progression of rebar corrosion. This can cause explosive phenomena due to expansion, rendering the reinforcement itself meaningless. To mitigate this risk, the Wood Preservation Center primarily employs a low-pressure resin injection method in accordance with the Ministry of Land, Infrastructure, Transport and Tourism specifications. The resin is thoroughly filled into the cracks, suppressing re-deterioration. Only then can the fiber sheets exhibit the planned reinforcement performance, protecting the structure over the long term. We provide reliable repairs and peace of mind reinforcement.

-

Reinforcement of the foundation using carbon fiber sheets begins with thorough surface preparation to ensure the complete removal of deteriorated areas and weak layers of the existing concrete. Since the soundness of the substrate affects the reinforcement performance, any floating or laitance must also be carefully treated. Next, a primer is applied to enhance the adhesion between the substrate and the resin. After that, appropriately prepared epoxy resin is evenly applied with a trowel or roller, and the carbon fiber sheet is affixed in the designated position. The installation is done while firmly pressing to ensure no air bubbles remain inside the sheet. Additionally, epoxy resin is applied again from the surface to sufficiently impregnate the entire fiber and form a reinforcement layer. In this way, the reinforcement integrated with the foundation is completed. To maximize the material properties, it is crucial to carry out each step without omission and with certainty.

-

Epoxy resin can be used not only as an adhesive for impregnating and fixing fiber sheets but also for various purposes to reinforce and protect concrete structures. In particular, epoxy resin mixed with carbon chop adds reinforcement effects to the resin itself, enhancing its ability to follow fine cracks in the substrate and improve localized stress dispersion performance. Additionally, even when structural reinforcement is not the goal, epoxy resin may be applied to concrete surfaces to improve durability by preventing water absorption and suppressing carbonation. At the Wood Preservation Center, we select suitable resins and methods for foundations, RC structures, and wooden components, addressing a wide range of needs from structural reinforcement to durability protection. We accurately diagnose the situation and provide construction services that maintain asset value over the long term.

-

When applying base coat mortar, reinforcing the substrate with carbon fiber sheets or aramid fibers not only restores aesthetics but also enhances structural strength. This allows for construction to be carried out from the outside of the foundation, minimizing impact on the interior and enabling work to proceed safely even while residents are present. Additionally, a top coat is applied to prevent UV degradation, providing long-term protection for the fiber sheets. If aesthetic appeal is a priority, selecting a finish using decorative plaster materials like Jolly Pat can create an upscale appearance. At the Wood Preservation Center, we achieve construction that balances not only repairs but also seismic resistance and durability while maintaining aesthetic quality. We guarantee a finish that meets professional standards and ensures the protection of our customers' asset value.

-

For the finishing after foundation reinforcement, high-performance finishing materials such as Foundation Coat 2 are used, which not only provide protection but also achieve a high-quality and luxurious appearance. Its excellent stain resistance and durability are major attractions, allowing for the maintenance of a beautiful condition over a long period. At the Wood Preservation Center, we provide consistent support from structural reinforcement to finishing, ensuring both seismic resistance and durability while also focusing on aesthetics in our construction proposals. We support the value of your important home or building from both strength and beauty, so please feel free to entrust us with your needs.

catalog(2)

Download All CatalogsCompany information

Our company has been responsible for the preservation work of important cultural properties, the health of general residences, the protection of assets, and crisis management for life. Since our establishment, we have been continuously improving our skills to meet various needs in modern society by utilizing the accumulated data from our surveys and construction projects. As a contractor engaged in the preservation work of national treasures and important cultural properties in Japan, we prioritize trust in terms of pricing, construction methods, and customer service. Please feel free to contact us with any inquiries.

![NEW MOS Method [Protects Against Mold!]](https://image.www.ipros.com/public/product/image/1aa/2000335029/IPROS7091746126330411870.GIF?w=280&h=280)