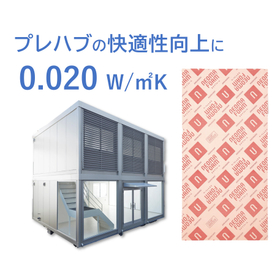

[Energy-saving and Carbon Neutral Measures] High-performance Insulation Material 'Silsaam'

Fuel costs are changing! Super low thermal conductivity insulation material "Silsaam"

Features of Silsaam Insulation Material: - Heat resistance temperature: 1000°C (top specification: 1200°C) - Thermal conductivity: 0.020 (at room temperature) / 0.034 (at 800°C) - Lower thermal conductivity than air - Insulation performance that is 5 to 10 times better than conventional insulation materials - A wide variety of lineups tailored to applications Benefits: - Reduction in CO2 emissions due to improved insulation - Decrease in fuel costs due to enhanced energy efficiency - Improvement in yield through optimization of thermal efficiency - Reduction in equipment costs due to lightweight design - Reduction in surface heat dissipation due to compact design - Expansion of volume due to thinning of insulation material We contribute to the reduction of rising fuel costs due to inflation, carbon pricing measures, and the realization of carbon neutrality. We also provide estimates for energy-saving effects.

Inquire About This Product

basic information

**About Silsaam Japan** ♦ We consistently manufacture from fumed silica, the raw material for microporous insulation, to the final product. ♦ In addition to high quality unique to raw material manufacturers, we pride ourselves on providing low-cost, high-value-added products. **Product Line** ■ Microporous high-performance insulation materials ■ High-performance vacuum insulation materials ■ Biodegradable fiber insulation materials ■ Calcium silicate insulation materials, etc. **Main Applications** ■ High-temperature applications: Steel / Non-ferrous / Plants / Power generation / Industrial furnaces, etc. ■ Fire-resistant applications: Construction (specific fire protection equipment) / Civil engineering (tunnel fire resistance), etc. ■ Low-temperature applications: Housing / Home appliances / Medical transport containers / Cold chain logistics, etc.

Price range

Delivery Time

Applications/Examples of results

Corresponding shapes - Flat - Two-dimensional curved surface - Three-dimensional curved surface Applications - Manufacturing processes for steel / non-ferrous metals / glass, etc. - Industrial furnaces (combustion furnaces and electric furnaces) - Semiconductor equipment - Hydrogen / ammonia production equipment - Thermal energy devices - Residential and architectural buildings It is adopted in various industries and applications around the world.

catalog(2)

Download All CatalogsNews about this product(1)

Company information

**What is Micro-porous High-Performance Insulation Material?** ♦ It boasts insulation performance superior to still air, making it the best high-performance insulation material in the world. ♦ It is called "micro-porous" due to its internal structure containing nano-level pores. ♦ Composed of amorphous silica particles with diameters of approximately 5 to 25 nm, infrared reflective materials like silicon carbide, and inorganic filaments, it is safe for the environment and human health. ♦ With a high heat resistance and made entirely of inorganic materials, it also serves effectively as an excellent fire protection material. ♦ Depending on the industry, it is referred to by various names such as "super high insulation material," "high-performance insulation material," and "micro-pore insulation material." **About Silsaam Japan** ♦ We consistently manufacture from the raw material fumed silica to the final product of micro-porous insulation material. ♦ Our strength lies in providing high-quality, low-cost, and high-value-added products to our customers. ♦ We actively engage in product development of insulation and fireproof materials using fumed silica, offering comprehensive solutions to various challenges faced by our customers.

![Residential Materials and Building Products Comprehensive Catalog 2023-2024 [Ichimura Sangyo]](https://image.www.ipros.com/public/product/image/d35/2000301416/IPROS2268654503825095296.PNG?w=280&h=280)