HARDOX wear-resistant tooth-shaped component product case study

Swedish steel wear-resistant steel plate HARDOX sprocket

The tooth-shaped parts made from HARDOX wear-resistant steel plates have high strength and excellent wear resistance, resulting in a longer lifespan for the equipment.

Sprockets and tooth-shaped components are parts used for power transmission. They are widely utilized in general industrial machinery such as machine tools and conveyor systems. Sprockets and tooth-shaped components made from HARDOX wear-resistant steel exhibit superior lightweight properties and strength, enhancing the performance of our customers' equipment. The mechanical properties of HARDOX wear-resistant steel provide high toughness, high hardness, and high strength even at low temperatures of -40°C, ensuring a long service life regardless of climate, terrain, or environment. 【Features】 ● High wear resistance, 12.5 times that of ordinary steel for HX500. ● High hardness, with a Brinell hardness of 500 for HX500. ● High strength, with a tensile strength of 1550 MPa for HX500. ● High toughness, with an impact value of 30 J (-40°C), resistant to cracking. ● No heat treatment or surface treatment required. ● Various grades and thicknesses can be selected based on application. ● Custom orders and bespoke designs are available.

Inquire About This Product

basic information

Mechanical properties of HARDOX450: ○ Yield strength: 1200 MPa ○ Tensile strength: 1400 MPa ○ Hardness (HBW): 450 ○ Impact toughness: 50 J (−40°C) ○ Wear resistance: 8 times that of SS400 ○ Service temperature: 250°C Material composition of HARDOX450: ○ Silicon Si: 0.7% ○ Manganese Mn: 1.6% ○ Phosphorus P: 0.025% ○ Sulfur S: 0.01% ○ Chromium Cr: 1% ○ Nickel Ni: 0.25% ○ Molybdenum Mo: 0.25% ○ Boron B: 0.004% ○ Carbon C: 0.23% ● For more details, please contact us or download the catalog.

Price information

Please contact us.

Delivery Time

※Please contact us.

Applications/Examples of results

■ Sprocket ■ Gear ■ Toothed component

Detailed information

-

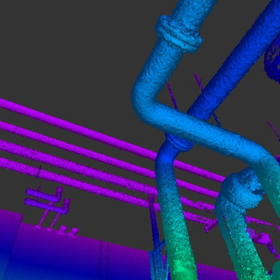

HARDOX550-t30 cut-out sprocket

-

HARDOX500 laser-cut sprocket

-

HARDOX500 laser-cut sprocket

-

HARDOX500 - Laser Cut Sprocket

-

HARDOX500 - Laser Cut Sprocket

-

HARDOX500 - Cut-out tooth-shaped parts

-

HARDOX550-t30 water-cooled cutting tooth profile processing

-

HARDOX500 - Laser Processing

-

HARDOX400 - Tooth-shaped parts laser processing

catalog(52)

Download All Catalogs

Company information

Kyowa Industrial Co., Ltd. responds to a wide range of customer needs through its businesses in material cutting and sales, machining, engineering services including design, manufacturing, and assembly, as well as factory maintenance and various equipment construction projects. As the core company of the group, Kyowa Industrial Co., Ltd. has expanded its operations from the repair and modification of machine tools in the automotive production industry at its founding to include the design of rationalization, labor-saving, and automation machinery, machining, material processing and sales, and collaborative operations with group company Intec Kyowa for piping, establishing a production system with integrated management from design to manufacturing, assembly, and installation. Kyowa Industrial Co., Ltd. not only processes and manufactures HARDOX wear parts, Swedish steel abrasion-resistant plates HARDOX, TOOLOX, and high-strength steel STRENX, but also focuses on high strength, high hardness, and high impact resistance, aiming to manufacture durable, lightweight, high-value-added production equipment by incorporating these features into the design of machinery. Furthermore, the Kyowa Group is also dedicated to the development of unique products. In this rapidly changing modern era, we, the Kyowa Group, are committed to responding to your needs and striving to deliver products that will satisfy you, working together as a unified company.

![Glass sliding door components [Counter sliding door, hanging door, upper hakama type]](https://image.www.ipros.com/public/product/image/713/2001400900/IPROS71180347461716676661.png?w=280&h=280)