An example of introducing lithium as a backup battery for a 2-ton reach truck that requires battery replacement every four years.

We would like to introduce a case study from a warehouse company that operates a 2-ton reach truck, which requires battery replacement every four years. They rented lithium batteries as a backup and started operations on the first day. The truck was discharging at a maximum of about 180A, making it challenging to use with the original lead battery capacity of 312Ah. After the replacement, the battery is charged with a rapid charger during breaks, resulting in shallow discharges and allowing for long hours of operation. 【Customer Overview】 ■ Operating Performance: Average of 6 hours per day, warehouse company ■ 2-ton Reach Truck: 62FBR20STE ■ Forklift Model Year: February 2016 ■ Battery Replacement: Approximately every 4 years ■ Rented Lithium-ion Battery: 48V280Ah *For more details, please refer to the PDF document or feel free to contact us.

Inquire About This Product

basic information

【Operating Status After Lithium Replacement】 ■Operating Time: 8.9 hours per day ■Charging Time: 0.7 hours per day, charged with a fast charger (120A setting) ■Maximum Discharge: 48% ■Breakdown of 14.5 hours online per day ・Idle Time: 5.0 hours (34%) ・Discharge Time: 8.9 hours (61%) ・Charging Time: 0.7 hours (4%) *For more details, please refer to the PDF document or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the PDF document or feel free to contact us.

Company information

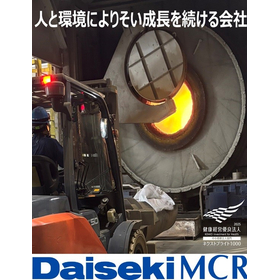

Our company restores batteries of forklifts that have shorter operating hours. Many companies have successfully achieved "cost reduction = 40%" and "energy-saving CO2 reduction = 98%" through restoration. Please feel free to contact us for more information.

![[Case Study of Lithium] Trial at Beer Factory 7FBH15](https://image.www.ipros.com/public/product/image/80c/2000651825/IPROS04987511814672622465.png?w=280&h=280)

![[Case Study of Lithium] Trial at the Shirakawa Printing Factory](https://image.www.ipros.com/public/product/image/7e0/2000727122/IPROS29679213117515022830.png?w=280&h=280)