Disadvantages of processing leaf springs with conventional die cutting and advantages of manufacturing with a laser processing machine.

**Leaf Spring**

A leaf spring is a type of spring that has a shape similar to a metal plate that has been processed by laser cutting or die cutting. Depending on the application (ranging from precision machinery manufacturing to connecting parts), there are various sizes and dimensions available. To maintain strength and durability, metal materials are used, and it is common to manufacture them primarily from stainless steel. The typical applications of leaf springs include motors, indoor units, generators, counterweights, doors, distribution boards, and various industrial machinery. The classification based on shape, material, and application is complex, and the demand for customized leaf springs is very high.

**Disadvantages of Conventional Die Cutting and Advantages of Laser Processing Machines**

With conventional processing methods, high-quality leaf springs can be created using die cutting or electrical discharge machining. However, the setup time is very long, and the costs are very high, making it difficult to achieve profitability in prototype or small-lot production. On the other hand, laser processing machines are very well-suited for prototype or small-lot production. At Comnet, we recommend the SEI series MERCURY FIBER laser processing machine for the production of leaf springs.

Inquiry about this news

Contact Us OnlineMore Details & Registration

Details & Registration

Related Links

With conventional processing methods, high-quality flat springs can be produced using die cutting or electrical discharge machines, but the setup time is very long and the costs are very high, making it difficult to be profitable for prototypes and small lot production. On the other hand, laser processing machines are very well suited for prototype or small lot production. Comnet proposes the use of the MERCURY FIBER laser processing machine for the production of flat springs.

The fiber laser MERCURY FIBER 1208 has arrived.

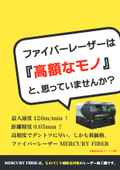

Maximum speed of 120m/min! Distance accuracy of ±0.05mm/1m! Processing speed is four times that of conventional machines.

Both processing speed and accuracy achieve world-class levels.

It features an ultra-compact body, one of the smallest classes for laser cutting machines for thin sheet metal with over 1kw.

With the world's highest specifications for both processing speed and accuracy! And at a low price! Free samples of processed thin sheet metal from the dedicated fiber laser processing machine are currently being offered.

Related product

Related catalog(4)

![[Utilization of Subsidies] A must-see if you're introducing a laser processing machine with subsidies! A booklet that provides a rough understanding of manufacturing subsidies.](https://image.www.ipros.com/public/catalog/image/01/4ca/522414/IPROS38689053559415068390.jpeg?w=120&h=170)

![[Free Sample of Metal Processing] Maximum speed 120m/min! Distance accuracy ±0.05mm! Processing speed is four times that of conventional machines! Fiber laser specifically for thin sheet metal.](https://image.www.ipros.com/public/catalog/image/01/515/490863/IPROS31531818327717731260.jpeg?w=120&h=170)