1~11 item / All 11 items

Displayed results

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us OnlineBefore making an inquiry

Download PDF1~11 item / All 11 items

This is a collection of case studies on embedded software from Abirika Co., Ltd. Although the cases are a bit old, they have been re-edited for publication. In addition to embedded software development, Abirika also provides a one-stop solution for re-manufacturing circuit boards due to changes in mounted chips, as well as the development and adjustment of mounted software. Abirika has 320 electrical and software IT engineers. The number of qualified personnel in electrical and software IT fields includes 126 in the basic information technology examination and 70 in the electrical construction technician examination and others. We also support embedded software for various electronic devices, as well as circuit design and prototyping of dedicated circuit boards for PC applications used in IoT, medical devices, and production equipment. If you are facing issues such as a shortage of software designers, wanting to develop labor-saving products or software, or needing to change the chips on your product's circuit board, and require changes to the mounted software as well, Abirika's technical expertise can help solve your problems.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Abirika Corporation is a partner for IP licensing with a major global microcontroller manufacturer, and we are widely engaged in embedded software, PC applications, and circuit board design, among other areas. Many of the projects we undertake are custom-made to client specifications, and most are confidential. This case study includes some devices for which we have received consent from clients to disclose. Since all were designed and manufactured to client specifications, they are not included in a sales catalog, but we invite you to take a look at a part of our business. We have 320 engineers in the electrical and software IT fields. The number of qualified personnel in electrical and software IT includes 126 in the Basic Information Technology Engineer Examination and 70 in the Electrician Examination and others. We also support embedded software and dedicated circuit board design and prototyping for various electronic devices, as well as PC applications and medical devices used in IoT, and production equipment. If you are facing challenges such as a shortage of software designers, wanting to develop labor-saving products or software, or needing to change chips on product circuit boards, and require changes to the software as well, Abirika's technical expertise can help solve your problems. We encourage you to make use of our services.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

IP license partners support customers who are inexperienced in using IP, developing ASICs, or implementing FPGAs. We have 320 electrical and software IT engineers. The number of qualified electrical and software IT professionals includes 126 in the Basic Information Technology Examination and 70 in the Electrician Examination and others. We also handle embedded software for various electronic devices, circuit design and prototyping for dedicated boards, as well as PC applications and medical devices used in IoT and production equipment. If you are short on software designers, want to develop labor-saving products and software, or need to change the chips on your product boards, and require changes to the software being implemented, we can solve your problems with Abilica's technical expertise. Specific examples of development include requests for educational materials that can be rewritten with software using microcontrollers for university classes, creating demo systems using new products at microcontroller manufacturers' exhibitions, and developing a complete set of circuit boards, firmware, and PC applications for industrial scalar robots. Abilica is a specialist in utilizing microcontrollers. Please make use of our services.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Abirika has obtained ISO 9001 certification, recognized for world-class quality in the design and management of machinery equipment manufacturing contracts (with specific certification scope). There are 450 mechanical design engineers, of which 334 are qualified in mechanical engineering. To accommodate various fields of design, we also hold 527 licenses for different types of CAD software. We can solve many of our customers' concerns, such as a shortage of designers, lack of in-house design skills for first-time projects, the desire to avoid missing orders during busy periods, the need for additional designers, the wish to enhance equipment, or the intention to automate to reduce employee burdens, through Abirika's design capabilities. We offer three types of services: 1. **Contract Design Services (Outsourcing)**: We have 11 domestic bases in Tokyo, Kanagawa, Chiba, Ibaraki, Aichi, and Fukuoka. 2. **Contract Design and Manufacturing Services for Various Equipment (Outsourcing)**: We have obtained ISO 9001 certification for the design and management of machinery equipment contracts at our First Technical Center (headquarters) and Second Technical Center. 3. **Engineer Dispatch Services (Engineer Dispatch)**: Dispatch business permit number: 13-306814. We encourage you to take advantage of our services. *ISO 9001 certification scope: Design and management of machinery equipment contracts at the First Technical Center (headquarters) and Second Technical Center.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This device is a packaging machine that wraps a box called a square wrap (the box to be packaged) without inverting it upside down. Additionally, it features a paper lifting section and a paper bending section that can wrap the paper in such a way that the cut edges of the paper are completely hidden (cosmetic folding). *This device has multiple patents pending. We design equipment tailored to our customers' needs. Abirika Co., Ltd. has obtained ISO 9001 certification (with a defined scope) for the design and management of mechanical equipment, recognized for its world-class quality. We can solve many of our customers' concerns, such as wanting to automate, enhance equipment, or reduce employee burdens through automation, with Abirika's design capabilities. Abirika's design services include: [Design and manufacturing services for various devices on a contract basis] with ISO 9001 certification obtained for design and management of mechanical equipment at the First Technical Center (headquarters) and the Second Technical Center. [Design services on a contract basis] with 11 domestic bases located in Tokyo, Kanagawa, Chiba, Ibaraki, Aichi, and Fukuoka. We encourage you to take advantage of our services.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Introducing the "Box Tying Device" handled by Abirika. This device uses a robot to wrap a ribbon in a cross pattern around a box and perform a bow knot. The control equipment includes eight stepping motor axes, two six-axis robots, and eleven air devices. It enables the automation of delicate tasks that have traditionally been performed by hand. 【Specifications (partial)】 ■ Size: 1,600 (W) × 1,895 (H) × 1,200 (L) ■ Control method: PLC (KEYENCE) ■ Control network: CC-Link ■ Control equipment - Eight stepping motor axes - Two six-axis robots - Eleven air devices *For more details, please feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"Yoketaro (tentative name)" is a multifunctional robot equipped with an axle encoder, ultrasonic sensors, a 3-axis accelerometer, and a Bluetooth module. It can detect vehicle body and driving information, enabling autonomous driving. Additionally, it can communicate via Bluetooth with PCs, tablets, and smartphones. We have numerous sales records to educational institutions (universities and vocational schools) for educational purposes in embedded software. 【Functions (partial)】 ■ Equipped with a Renesas Electronics RX230 microcontroller ■ Capable of autonomous driving with independent motor control for left and right ■ Features an encoder function on the axle ■ Equipped with ultrasonic sensors (transmitter and receiver) for obstacle detection ■ Detects vehicle body and driving information with a 3-axis accelerometer *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

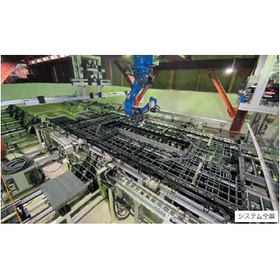

"Robotaras" is a system that can automatically perform rebar assembly work by alternately attaching and detaching a "rebar holding jig" and a "rebar tying machine" at the tip of a robotic arm. By using robots for rebar assembly, it is possible to improve productivity as monotonous and repetitive tasks are performed over the long term. Our company was responsible for the design technology support of this system. 【Features】 ■ Automatic attachment and detachment of the "rebar holding jig" and "rebar tying machine" ■ Ability to automatically perform rebar assembly work ■ Possibility to improve productivity as monotonous and repetitive tasks are performed over the long term *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Automatic Bottle Decoration (Ribbon Tying) Device" is a machine that automatically performs the folding of decorative paper and the tying of decorative ribbons to decorate four-go bottles. When bottles (24 units), washi paper (200 sheets), and ribbon (500m) are supplied, decorated bottles are produced at an average cycle time of 28 seconds per bottle. The washi paper is taken out one sheet at a time from the stocker, processed for creasing with a pressing mechanism, and then placed over the bottle to carry out the paper folding process. The decorative ribbon is automatically cut to a fixed length, placed over the folded bottle after going through the knotting process, and finally tied in a bow to complete and discharge the bottle. 【Features】 ■ No experience required for bow tying, fully automatic and hassle-free ■ Stable quality and beautiful finish ■ Achieves automation of bow tying ■ Adopted in the ginjo sake line of a certain sake brewery ■ Elegant appearance enhances product value *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Abirika Co., Ltd. provides high technological capabilities to "manufacturing companies" in various fields such as industrial robots, plant equipment, automobiles, medical devices, elevators, and food. Our technical fields include mechanical design that supports the evolution of mechatronics and automation technology, electrical and electronic design that challenges the creation of next-generation electronics, and in-house development that creates new brands. We will leverage the technological capabilities we have cultivated so far to focus on in-house development of original products. Please look forward to our challenge of creating something new that does not exist in the world, rather than imitating something else. 【Business Overview】 ■ Design and Development Engineering ・Mechanical Design ・Electronics Design ・In-house Development ・Engineering Outsourcing *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Abirika Co., Ltd. is a design and development engineering company that supports our customers' manufacturing based on over half a century of accumulated technology. We realize the equipment that no one has ever seen or created before. "It would be great if we could do this," we make it happen. 【Examples of Design and Manufacturing】Excerpt ■ Bowknot Device: A fully automatic device that ties a solid knot and a bow knot under the neck of a one-sho bottle. ■ High-Speed Alignment Parallel Link Robot: A device that recognizes products flowing on a conveyor through image recognition and aligns them at high speed. ■ Protective Sheet Application Device: A device that applies protective sheets to sheet metal panels (products). ■ Reinforcement Assembly Automation System: An automation system for assembling reinforcement bars in concrete structures. *For details, please request materials or view the PDF data from the download.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration