46~73 item / All 73 items

Displayed results

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us OnlineBefore making an inquiry

Download PDF46~73 item / All 73 items

Waterway Use Impact-Resistant Rigid Polyvinyl Chloride Pipe HI-VP 25 × 1m (1 set: 4 pieces) (JIS K 6742 standard product) Nominal diameter (approximate inner diameter): 25 mm Outer diameter: 32.0 mm ± 0.2 mm Thickness: 3.5 mm ± 0.3 mm Weight: 0.44 kg (reference) Color: Dark blue Features: This is a PVC pipe with excellent impact resistance. ■ HIVP pipe is strong against impact Standard VP pipes have low strength against impact, which can lead to breakage during installation or use. Additionally, at low temperatures, their impact resistance decreases further, making them more prone to cracking, which has been a problem particularly in cold regions. Therefore, the material has been improved, significantly enhancing the performance against impact, resulting in the HIVP pipe. ■ Reasons for the strength of HIVP pipe Standard PVC resin is mixed with impact resistance modifiers (such as ABS, MBS, EVA, acrylic rubber, and chlorinated polyethylene, which have rubber-like properties) as reinforcing agents. By mixing this reinforcing agent at about 5-20%, the particles of the reinforcing agent absorb impact energy and become more resilient, preventing breakage.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In response to the changes in the market, Miyata Industrial Co., Ltd. manufactures purification tank components for customers with our cultivated proposal capabilities and speedy responses, while also providing a comprehensive range of necessary components beyond just the water treatment field, ensuring reliable quality in our products. We primarily manufacture products using techniques for processing polyvinyl chloride (PVC) pipes and PVC sheets. We accommodate not only mass production but also small lots of various products. If you are considering the production of PVC products in small lots that cannot be handled with molds, please feel free to consult us. Our goal is to exceed customer expectations in our contributions. [Contents] ■ Support for the manufacturing of purification tank components and water treatment-related products ■ Proposal model chart ■ Manufacturing of PVC and plastic processed products ■ Examples of products and handled products ■ Company overview ■ Company history ■ Locations *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We process and sell cut PVC pipes. Please feel free to consult us about any cutting processing of plastic pipes, resin pipes, water pipes, electrical conduits, heat-resistant pipes, fire-resistant VP pipes, fire-resistant double-layer pipes, drain pipes, and more. Through pre-cut processing, prefabrication, and unitization of PVC piping, we streamline on-site construction and provide high-quality PVC pipes in a short delivery time. Our production bases are located in Aichi, Tochigi, Fukuoka, Mie, and Saitama (cooperating factories), allowing us to produce and deliver near our customers. ■ Processing Materials Rigid polyvinyl chloride pipes: VP pipes (water pipes), VU pipes (thin-walled pipes), VE pipes (electrical conduits), HIVP pipes (impact-resistant pipes) in deep blue, HT pipes (heat-resistant pipes) in reddish-brown, FSVP pipes (fire-resistant pipes) in green, drain pipes, transparent pipes, perforated pipes, colored pipes (weather-resistant specifications, ivory, milk white, etc.), square pipes, and air conditioning drain pipes VP and VU. <Address of Sales Offices and Production Bases> Nagoya Sales Office / Nagoya Factory: Hiruma-cho, Tsushima City, Aichi Prefecture Mie Factory: Anou-cho, Tsu City, Mie Prefecture Fukuoka Sales Office / Fukuoka Factory: Urushi, Kama City, Fukuoka Prefecture Utsunomiya Sales Office / Tochigi Factory: Interpark, Utsunomiya City, Tochigi Prefecture Cooperating Factory: Kawajima Town, Hiki District, Saitama Prefecture

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

■ Mass production of cut pipes at low cost With our unique technology, we can perform secondary processing on PVC pipes for various applications (such as winding cores, cores for sheets and films). We can quickly and cost-effectively provide large quantities of PVC pipes cut or lathed to your specified dimensions. Example: 3 inches (VP75), 6 inches (VP150) ■ High precision cutting with a tolerance of ±0.5 mm Using a dedicated automatic cutting machine, we can achieve high precision cuts with a tolerance of ±0.5 mm for PVC pipes with outer diameters of φ18 to φ89 (VP13 to VP75, VE14 to VE82, VU30 to VU75). *Please consult us as the tolerance for long dimension pipes varies depending on the length. ■ Achieving a minimum cut size of 2 mm We can cut PVC pipes with outer diameters of φ18 to φ48 (VP13 to VP40, VE14 to VE42, VU30 to VU40) from a minimum width of 2 mm. (Small width cuts, cross cuts, rings, etc.) ■ Cutting of large diameter pipes is also possible PVC pipes with diameters of 114 mm or more (VP100 to 300, VU100 to 600) can be cut using a semi-automatic cutting machine or manual processing. ■ Finishing We also provide services for finishing the cut surfaces with lathe processing, removing chips, deburring, chamfering, marking and numbering, packaging, and more.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is a pipe rack made from PVC pipes. It is very convenient as it allows for easy organization and storage of long pipes and other items in a simple rack! We aim to maintain cleanliness and want our factory to exude a sense of cleanliness at all times! Our production bases are located in Tsushima City, Aichi Prefecture; Tsu City, Mie Prefecture; Kama City, Fukuoka Prefecture; Utsunomiya City, Tochigi Prefecture; and Kawashima Town, Hiki District, Saitama Prefecture, allowing us to regularly deliver products from the factory closest to our customers. 【Usage】 It can be used as a pipe rack. 【Features】 - Dimensions can be customized to the specified size that fits the site.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The sprinkler pipe is a PVC pipe with holes designed for watering. It is manufactured using techniques for drilling, cutting, bonding, and PVC welding. It can be used as a heat exchanger to cool hot water by directly exposing it to the atmosphere, or for spraying chemicals and other substances. Additionally, it can also be used for releasing gases such as air. For example, it can be used to send air into water to increase oxygen concentration or for stirring purposes. By utilizing pre-cut and prefabricated PVC piping, as well as modularization and unitization, we streamline on-site construction and provide high-quality PVC piping with short delivery times. Our production bases are located in Tsushima City, Aichi Prefecture; Tsu City, Mie Prefecture; Kama City, Fukuoka Prefecture; Utsunomiya City, Tochigi Prefecture; and Kawashima Town, Hiki District, Saitama Prefecture, allowing us to regularly deliver products from factories near our customers. Miyata Industrial Co., Ltd. https://www.mcl-miyata.co.jp TEL: 0567-28-3029 / FAX: 0567-24-8564 Email: info@mcl-miyata.co.jp

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We manufacture custom strainers and filtration filters by processing PVC pipes. It is possible to produce custom strainers and filters used for foreign matter removal and equipment protection. We can accommodate the required size, hole diameter, and hole pitch. Our production bases are located in Tsushima City, Aichi Prefecture; Tsu City, Mie Prefecture; Kama City, Fukuoka Prefecture; Utsunomiya City, Tochigi Prefecture; and Kawagoe City, Saitama Prefecture, allowing us to regularly deliver products from a factory near you. Material: PVC

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We are a specialized company that mass-produces adhesive connections for PVC parts such as vinyl chloride pipes, fittings, and valves. Our production bases are located in Tsushima City, Aichi Prefecture; Tsu City, Mie Prefecture; Kama City, Fukuoka Prefecture; Utsunomiya City, Tochigi Prefecture; and Kawajima Town, Hiki District, Saitama Prefecture, allowing us to regularly deliver products from the factory closest to our customers. 【Cutting Processing】 We cut vinyl chloride pipes for various applications using automatic cutting machines, manual saws, and jigs. If you need a large quantity of vinyl chloride pipes cut to specified dimensions, we can respond quickly and at low cost. 【Adhesive Joining】 We apply adhesive to the cut vinyl chloride pipes and join them using fittings such as sockets, elbows, and tees. For large-diameter piping that is difficult to bond at factories or job sites, we can also manufacture by using pipe cutting machines, pipe insertion machines, and dedicated jigs. 【Manufacturing Support through Pre-processing】 By using factory-produced piping units or piping kits (pre-cut pipes + fittings), you can improve quality and increase efficiency in on-site piping assembly, while also eliminating pipe offcuts, which helps reduce costs. We can accommodate mass production, so please consult us even for short delivery times.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

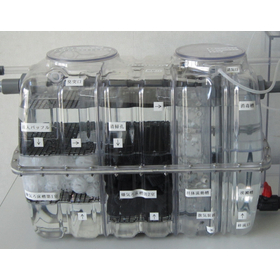

We have created a 1/4 scale realistic miniature model of a purification tank. By using a small blower to supply air to the airlift and aeration devices, we replicate the actual water flow and the movement of the fluid carrier caused by aeration. Made of transparent PVC, you can see the internal structure, water flow, and movement of the carrier. How about placing one in your office as an educational material or as an interior decoration? Material: PVC (Vinyl chloride)

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

【Features】 - Made of PVC, so it does not rust. - Connection is easy; simply glue PVC pipes (VP30, VP40) to the sockets on both sides. For connecting VP50 pipes, you can glue a TS socket 50A (sold separately) to the inlet. - The main body has a flexible union structure, allowing you to loosen the bag nut for removal. - It can also be used for horizontal piping. In that case, please install it with the "top" mark facing up. 【Applications】 - Can be used as a check valve for the discharge pump piping of septic tanks. 【Materials】 (TS inlet) PVC, (main body union) PVC, (valve unit) 40/50A: PVC/EPDM (30A: NBR), (O-ring) 40/50A: EPDM (30A: NBR) 【Connection Method】 TS type 【Operating Temperature Range (°C)】 0 to 50 (reference)

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Distribution Adjustment Air Valve 【Features】 - It has a scale from 50 to 100, making it easy to adjust the air distribution amount. - Traditionally, two air valves and one tee fitting were used for piping, but with the installation of one distribution adjustment air valve, piping can be made compact. - The color of the handle allows for identification by application. 【Applications】 - Used in the internal piping of a septic tank to distribute the air volume from the blower. Three-Way Adjustment Valve 【Features】 - It has a scale from closed to 50-100, allowing for air volume adjustment. - The direction of air flow can be switched by adjusting the position of the handle. Air flow can be adjusted to one direction, two directions, or fully closed. - The color of the handle allows for identification by application. 【Applications】 - Used in the internal piping of a septic tank to adjust the air volume from the blower.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

- Connection diameter: Compatible with 40A/50A types The connection can be easily installed by simply gluing PVC pipe VP40 to the sockets on both sides. If connecting PVC pipe VP50, you can use a TS socket 50A (sold separately) glued to the receiving end. * There is also a connection diameter: 30A type available (for PVC pipe VP30). - Structure with a union for easy pump removal The main body has a flexible union, allowing for easy removal by loosening the bag nut. - Compact design The main body is compactly designed, making it possible to install in narrow piping spaces. - The main body is made of polyvinyl chloride (PVC) Being made of resin, there is no worry about rust. Additionally, due to being made of PVC, it also has excellent chemical resistance.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

- The scale from 0 to 100% is marked in 5% increments, making it easy to adjust the air volume. - There are six types of valves with different flow characteristics, allowing you to use them within the desired adjustment range for your specific application. The order from standard to low airflow types of valves is: Standard → Alpha → Beta → 1 → 1.5 → 2. - There are five colors for the handles, enabling identification by color based on application. Example: Red: Backwash, Blue: Aeration, Yellow: Air Release, Gray/White: Airlift.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

PVC Damper JIS10K Flanged Type 50-300A Other connection methods include JIS5K flanged type, socket type, and duct flanged type. Opening and closing adjustments can be made using the handle lever. Material: PVC

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The inner diameter of the aeration pipe can be directly connected and fixed with adhesive to PVC pipes. Additionally, we offer original fittings for aeration pipes (such as flanged elbows and tees), allowing us to manufacture them in L-shaped or T-shaped configurations to your desired length (within 500 mm). Sizes (outer diameter/inner diameter) 30/18 mm: 13A (airflow capacity approximately 15–80 liters/min) Sizes (outer diameter/inner diameter) 36/26 mm: 20A (airflow capacity approximately 18–100 liters/min) The main body is molded using excellent molding technology to combine particles and powders, resulting in uniform air bubbles. The pore diameter is uniformly molded, resulting in very little pressure loss. Due to the low pressure loss, the motor burden is reduced, leading to energy savings. The particles themselves have evenly distributed fine pores, allowing for uniform diffusion of micro air bubbles, which reduces clogging over long periods of use. Since the material is P.P, it will not break even if dropped during work. The product is very lightweight, making it easy to carry during work and handle during piping. The optimal cleaning methods are water washing, backflow, and weak acid (20–30%). Material: Made of P.P.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The main body is a porous material. With excellent molding technology, particles and powders are bonded and molded, allowing for uniform air bubbles to form. Since the pore diameter is uniformly molded, the pressure loss is very minimal. Due to the low pressure loss, the motor burden is reduced, leading to energy savings. The particles themselves have uniformly fine pores, allowing air to diffuse evenly and reducing clogging over long-term use. Because the material is P.P., it will not break if dropped during work. The product is very lightweight, making it easy to handle during transportation and piping. The optimal cleaning methods are washing with water, backflow, and weak acid (20-30%). There are proven results in industrial wastewater and sewage treatment plants both nationwide and overseas.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

• PVC welding processing is carried out by skilled craftsmen. • We pay close attention to prevent leaks or damage from chemicals, water, air, and pressure, allowing us to provide products with stable quality. • By applying PVC welding technology, we can also manufacture special joints and tanks that do not have standard specifications in commercially available fittings. <Advantages of PVC Products> 1. Excellent mechanical safety. 2. Superior creep resistance. 3. The softness of PVC products can be freely changed by adding plasticizers. 4. Excellent chemical resistance. 5. Transparent. 6. Excellent adhesion and printability. 7. Flame retardant. 8. Good electrical properties. 9. In the case of soft PVC products, a texture similar to rubber-like elastomers or leather can be obtained. 10. Excellent durability. 11. Excellent fatigue resistance. <Disadvantages of PVC Products> 1. Low impact strength at low temperatures. 2. The continuous use temperature is somewhat low. 3. In the case of soft PVC products, there may be leaching of plasticizers. 4. High viscosity during melting, making it unsuitable for large-scale injection molding.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

■We offer hole processing (slit processing, strainer processing) using equipment such as automatic drilling machines, depending on the size of the PVC pipes, making it possible to accommodate mass production. We will perform secondary processing on the PVC pipes according to your specifications, including hole diameter, hole pitch, through holes, and staggered holes. Additionally, we will cut the perforated PVC pipes to your specified length. ■For PVC pipes with an outer diameter of φ18 to φ26 (VP13 to 20) and electrical conduits (VE14 to 22), we can perform hole drilling with a diameter of φ1 to φ5 mm with a tolerance of ±1 mm. ■In terms of hole types, we can accommodate requests for not only single-sided holes but also through holes and staggered holes. We also tap for screw holes (male threads) for nozzle attachment. ■We will handle dimension cutting, chamfering, chip removal, packaging, and other specifications for perforated pipes as per your requirements. ■By offering pre-cutting and prefabrication of PVC piping, as well as modularization and unitization, we streamline on-site construction and provide high-quality PVC piping in a short delivery time.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

■ We will bend rigid PVC pipes according to their intended use using our unique technology. ■ If you need a large quantity of PVC pipes processed to your specified bending dimensions (R dimensions), we can provide them quickly and at a low cost. ■ For PVC pipes with outer diameters of φ18 to φ38 (water supply pipes VP13 to 30 and electrical conduits VE14 to 22), we can perform bending using dedicated molds, with VP13 at R21 or more, VP20 at R37 or more, VP25 at R32.5 or more, and VP30 at R35 or more. ■ Mass production of bent PVC pipe products is possible. We mainly process general PVC pipes (VP and VU pipes, gray color), electrical conduits (VE pipes, gray color), impact-resistant PVC pipes (HIVP and HIVE pipes, navy blue and dark blue), heat-resistant PVC pipes (HT pipes, reddish-brown), and transparent PVC pipes (clear, translucent) to create special PVC piping, large bends, bend pipes, U-shaped pipes, loop pipes, S-shaped pipes, R-bent pipes, and crank pipes. By utilizing ready-made PVC pipes, they can be used for various applications. Additionally, reducing the number of joint connection points can serve as a measure to mitigate water leakage. Please consult us regarding sizes, shapes, and R dimensions.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is a collection of case studies that introduces some of Miyata Industrial's technology for processing PVC pipes. It includes photographs of secondary processed products such as cut pipes, perforated pipes, half-split pipes, and assembled products of pipes and fittings (prefabricated piping) involving cutting, drilling, adhesive bonding, welding, bending, sleeve processing, machining, and assembly. Through pre-cutting and prefabrication of PVC piping, as well as modularization and unitization, we streamline on-site construction and provide high-quality PVC piping in a short delivery time. We offer products with comprehensive capabilities and reliable quality for all types of PVC piping. For more details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

■ Low-cost mass production of cut pipes Using our unique technology, we cut PVC pipes and resin pipes to specified dimensions according to various applications. We can respond quickly and at low cost when large quantities are needed. ■ High-precision cuts with a tolerance of ±0.5 mm Using dedicated automatic cutting machines, we can achieve high-precision cuts with a tolerance of ±0.5 mm for PVC pipes with outer diameters ranging from φ18 to φ89 (VP13 to VP75, VE14 to VE82, VU30 to VU75). ■ Achieving a minimum cut dimension (minimum width) of 2 mm We can cut PVC pipes with outer diameters ranging from φ18 to φ48 (VP13 to VP40, VE14 to VE42, VU30 to VU40) starting from a minimum cut dimension (minimum width) of 2 mm. ■ PVC pipes with a diameter of 114φ or more (VP100 to 300, VU100 to 600) can be cut using semi-automatic cutting machines or manual processing. Additionally, we can handle secondary processing such as chip removal, deburring, chamfering, as well as drilling, bending, welding, bonding, and screw machining. <Offices and Production Bases> Nagoya Sales Office, Nagoya Factory (Hiruma-cho, Tsushima City, Aichi Prefecture), Mie Factory (Ano-cho, Tsu City, Mie Prefecture), Fukuoka Sales Office, Fukuoka Factory (Urushio, Kama City, Fukuoka Prefecture), Utsunomiya Sales Office, Tochigi Factory (Utsunomiya City, Tochigi Prefecture), Partner Factory (Hiki-gun, Saitama Prefecture)

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

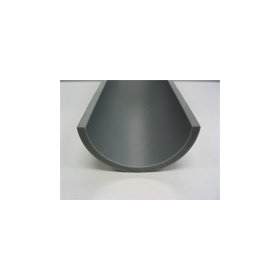

It is possible to manufacture half-split PVC pipes and half pipes by secondary processing of rigid PVC pipes, general PVC pipes (VP, VU), electrical conduits (VE), impact-resistant PVC pipes (HIVP), heat-resistant PVC pipes (HTVP), fire-resistant VP pipes, transparent PVC pipes, and others. The length of the half-split PVC pipes can be cut to your desired dimensions, up to 4 meters. We also accommodate finishing processes such as chamfering. By pre-cutting and prefabricating PVC piping, as well as modularizing and unitizing, we streamline on-site construction and provide high-quality PVC piping in a short delivery time. We can regularly deliver mass-produced products from nearby production bases. <Address of Sales Offices and Production Bases> Nagoya Sales Office / Nagoya Factory: Hiruma-cho, Tsushima City, Aichi Prefecture Mie Factory: Ano-cho, Tsu City, Mie Prefecture Fukuoka Sales Office / Fukuoka Factory: Urushi, Kama City, Fukuoka Prefecture Utsunomiya Sales Office / Tochigi Factory: Interpark, Utsunomiya City, Tochigi Prefecture Cooperating Factory: Kawajima Town, Hiki District, Saitama Prefecture In addition to half-split pipes, we are also mass-producing various secondary processed products of resin pipes, allowing for speedy delivery even for large orders.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We are a specialized manufacturer of PVC piping that performs adhesive connections between PVC pipes and fittings to mass-produce prefabricated piping. Utilizing our expertise in PVC adhesion and welding techniques, we carry out assembly work. Through pre-cutting and prefabrication of PVC piping, as well as modularization and unitization, we streamline on-site construction and provide high-quality PVC piping in a short delivery time. By using factory-produced piping units or piping kits (pre-cut pipes + fittings), we can improve quality and increase efficiency in on-site piping assembly, while also helping to reduce costs as there is no waste from pipe offcuts. We are capable of mass production, so please consult us even for short delivery times. Additionally, by using our original PVC molded parts and special fittings, we can create various piping shapes. We have production bases in Nagoya, Mie, Fukuoka, Saitama, and Tochigi, allowing us to deliver from factories close to your manufacturing sites.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We process mainly rigid polyvinyl chloride sheets (PVC plates), PVC pipes, and PVC fittings to manufacture various products. We are capable of processing various vinyl chloride products using cutting techniques with NC routers and lathes, as well as vinyl welding skills by craftsmen. We can also process materials such as transparent PVC, impact-resistant PVC, heat-resistant PVC, and flexible PVC. We manufacture custom-made plastic transparent aquariums, special boxes, devices, tanks, units, test trays, boxes, machine covers, containers, and more. Additionally, we can produce items using techniques such as cutting, machining, drilling, bending, gluing, and lathe work. All products are made to order, from prototypes to mass production, tailored to customer requests. <Advantages of PVC products> 1. Excellent mechanical safety. 2. Superior creep resistance. 3. The softness of PVC products can be freely changed by adding plasticizers. 4. Excellent chemical resistance. 5. Transparent. 6. Excellent adhesion and printability. 7. Flame retardant. 8. Good electrical properties. 9. Excellent durability. <Disadvantages of PVC products> 1. Low impact strength at low temperatures. 2. Slightly low continuous heat resistance temperature.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We accept custom orders for soft PVC vibration-damping joints, canvas joints, flexible joints, and expansion joints based on the total length dimensions and flange sizes required on-site. The main material used is soft polyvinyl chloride sheet, which will be processed according to the size specifications. Connection methods can be manufactured according to your specifications, including socket, duct flange, JIS 5K flange, JIS 10K flange, PVC sheet processed flange, and band tightening, among others. We are open to consultations regarding the total length dimensions of the main body and flange shapes (rounded corners) to suit your application. These joints are used for connections between vibrating equipment, such as blowers, and ducts, as well as in places where expansion and flexibility are required. Material: Soft PVC.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

PVC Dampers Connection Size and Method Socket (50A, 65A, 75A, 100A, 125A, 150A, 200A, 250A, 300A) Flange JIS 5K (50A, 65A, 80A, 100A, 125A, 150A, 200A, 250A, 300A) Flange JIS 10K (50A, 65A, 80A, 100A, 125A, 150A, 200A, 250A, 300A) Duct Flange (50A, 65A, 80A, 100A, 125A, 150A, 200A, 250A, 300A) *Custom specifications can be manufactured upon request. PVC Dampers, Socket Type, Flange Type (5KF, 10KF), Duct Flange Type, 50-300A Material: Made of PVC The opening and closing can be adjusted using the handle lever. In addition, we manufacture vibration-damping joints made of soft PVC, canvas joints, expansion joints, soft flexibles, and other products related to air conditioning duct systems as well as plastic and resin processing products.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

A large specific surface area can be obtained, and a biofilm is formed on the carrier, allowing microorganisms to efficiently process organic matter and oxygen through the movement of the carrier. The contact material can be filled in the contact aeration tank, allowing for the attachment of biofilm.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We offer a variety of products, from plastic special parts to original fittings made of PVC. Since we handle many items that are not available on the market, please feel free to consult us if you have any issues with air piping inside septic tanks, adhesive connections of rigid PVC pipes, or the routing of PVC piping.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration