1~26 item / All 26 items

Displayed results

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us Online1~26 item / All 26 items

The "SWM-P5" is a mobile 5-axis machining machine developed with the innovative idea of "bringing the machine close to the workpiece." If placed on a layout table or a grooved plate, it can be set up by the customer themselves and allows for simultaneous 5-axis machining using tip point control. Using cutting tools such as ball end mills, it can perform "modeling" at a 1:1 scale of a car on clay, foam, and some synthetic wood materials. 【Features】 ■ Smooth mobility and setup ■ Compact storage with two-stage elevation ■ Compact 5-axis head ■ Easy setup ■ Compatible with CAD/CAM operations *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a case study of the "Self-Propelled NC Long Material Processing Machine." This machine is equipped with a self-propelled vice that features a servo motor attached to the air clamp vice included with the long material processing machine. The air clamp vice automatically positions itself according to the program, eliminating the need for customers to manually adjust the position. 【Case Overview】 ■ Application: Long aluminum materials, aluminum sashes, etc. ■ Main Industries: Construction materials industry, etc. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a case study of the "Transport NC Panel Processing Machine." This panel processing machine is equipped with a roller conveyor installed on the machine frame and features a work pusher on the machine gate to discharge workpieces to the next process. It is a custom specification tailored to the customer's workpieces and factory conditions. 【Case Overview】 ■ Purpose: Processing of panel materials and automation to the next process ■ Main Industries: Customers involved in various panel processing *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a case study of the "Gate-Type Screw Tightening Machine." This machine places a sheet material on the frame, performs pre-drilling, and then uses a screw tightening unit to secure the sheet. Two gate-type units are prepared to run on a single machine frame; one unit handles the pre-drilling, while the other performs the screw tightening. 【Case Overview】 ■ Application: Mounting sheets onto truck beds, screwing into building materials ■ Main Industries: Truck body manufacturing industry, housing materials industry *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a case study of the "Vertical Lathe Function Composite Gantry NC Machining Center." This is a 5-axis machine (simultaneous 3-axis) equipped with a workpiece rotating table mounted on the table of a 3-axis machine that moves back and forth and the spindle moves left, right, and up and down. It is equipped with a tool holder that can move vertically along the spindle, allowing for lathe processing while rotating the workpiece. [Case Overview] ■ Application: Processing of carbon before quenching ■ Main Industry: Industrial Machinery Industry *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a case study of the "Punch Press Equipped NC Long Material Processing Machine." This long material processing machine is equipped with a punch press unit next to a swiveling spindle (SA type). It achieves high-speed processing for workpieces with numerous hole operations, mainly for angle and channel shapes. It can perform hole processing at approximately 20 times the speed of processing done with an end mill. 【Case Overview】 ■ Application: For customers processing long aluminum materials such as aluminum sashes and curtain rails ■ Main Industry: Building materials industry, etc. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a case study of the "Horizontal Machining Center." This is a dedicated machine that clamps the workpiece in a special vise and performs machining from the side. It drills horizontal holes, followed by chamfering and tapping. Since multiple workpieces can be mounted, efficient machining can be achieved. Please feel free to consult us when you need assistance. 【Case Overview】 ■ Application: For mass production parts ■ Main Industry: Parts manufacturers *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Here is an introduction to a case study of a "V groove processing machine." This machine cuts a V groove into a steel plate and bends the V part to achieve a small bending radius and an inner angle close to a sharp angle. By adjusting the height of a multi-head cutting unit by 0.1mm, it can perform four grooves in a single cutting operation, making it efficient. 【Case Overview】 ■ Application: Grooves for bending steel plates (sharp angles, minimum bending radius) ■ Main Industry: Sheet metal manufacturing companies *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a case study of the "Dual-Head Milling Machine for Resin." There are two large cutters arranged horizontally, and milling can be performed as the workpiece passes between these cutters. Since we process the resin stacked on the table, we can handle a large number of pieces at once. After the side processing is completed once, the table rotates 90°, allowing for processing on four sides in one cycle. [Case Overview] ■ Application: Mirror finishing of resin sides ■ Main Industries: Light guide plate and resin material manufacturers *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We accept orders for the production of "small end processing machines." These are specialized machines for cutting and hole processing at the ends of small aluminum long materials, capable of inserting the workpiece for cutting and hole drilling. Please feel free to consult us when you need assistance. 【Case Overview】 ■ Application: Cutting and hole processing at the ends of small aluminum long materials ■ Main Industries: Construction materials industry, etc. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a case study of our "NC Cutting Machine with Fixed Dimensions." Thanks to NC control, it is possible to perform high-precision processing by feeding the workpiece. The workpiece is securely fixed by clamps from the sides and above, ensuring reliable cutting. After cutting, the workpiece is automatically discharged to the front. 【Case Overview】 ■ Application: Cutting processing of aluminum materials and resin materials ■ Main Industries: Aluminum industry, resin industry *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a case study of the "Long-Length Gantry Type 5-Axis Machining Center." The table length is 7000mm, and the suction area is divided into four sections, allowing for adjustments based on the workpiece size. With a compact 5-axis head, it can process at various angles, and by equipping it with a saw blade, cutting operations are also possible. 【Case Overview】 ■ Applications: Long-length resin panels, long-length aluminum materials ■ Main Industries: Building materials industry, bus and truck industry, etc. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a case study of the production of a "long material and panel material composite machine." At the request of a residential building materials manufacturer, we equipped the panel processing machine with a vice that allows for the processing of both "panel materials" and "long materials" with a single machine. During panel processing, the workpiece is suctioned to the table, and during long material processing, the vice, which is retracted, is pulled out into the processing area for machining. 【Case Overview】 ■ Application: For customers processing aluminum long materials and aluminum panels ■ Main Industry: Building materials industry, etc. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We accept orders for the "Low-Profile Gantry Model Processing Machine." This gantry-type model processing machine has a low height, making it suitable for large and thin workpieces such as wooden patterns for casting tables. Due to its low center of gravity, it excels not only in drilling but also in milling operations. 【Case Overview】 ■ Application: For relatively thin and large wooden patterns (such as wooden patterns for casting tables) ■ Main Industry: Wooden pattern industry *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We accept orders for the manufacturing of "carbon sheet processing machines." Materials can be set on the suction table, allowing for milling and hole processing to achieve the desired thickness. The main spindle is equipped with a dust collection hood, enabling processing while collecting chips. This machine, with its table movement, can process the thickness of sheet materials with high precision. 【Case Overview】 ■ Application: Drilling, milling, and finishing processing of sheet materials such as carbon ■ Main Industries: Material manufacturers, etc. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We accept the production of "rivet machines." It is possible to insert rivets into a perforated plate and a perforated frame, and then fasten the rivets. The hydraulic press ensures secure fastening. 【Case Overview】 ■ Application: Fastening aluminum plates to a frame with rivets ■ Main Industry: Truck body construction *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "SWM Full Cover Type" is a compact NC model machining machine designed for space-saving with a smaller housing. It comes standard with an "automatic tool length measurement device," "12-tool ATC or 24-tool ATC," "AI contour control II," and a "4GB data server." You can start machining immediately after installation by using CADCAM and other software. 【Features】 ■ NC Device: FANUC 0i-MF PLUS ■ Spindle Shape: BT30 or BT40 pull stud MAS-1 type (tooling sold separately) ■ ATC: Disc type 12-tool ATC ■ Maximum Spindle Power: 3.7 kW ■ Maximum Speed: 10,000 min-1 *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "SWMG series" is a space-saving design NC gantry-type 3-axis machining center, where the crossbeam moves back and forth, compared to table-moving models. The structure has the running part located at the top, making it less susceptible to the effects of chips. By installing a dust collection hood and dust collector at the rear of the machine as an option, cleaning can be completed simply by blowing the chips generated during cutting into the dust collection hood with air blow. 【Features】 ■ Space-saving ■ Resistant to chips ■ Abundant optional specifications ■ Well-equipped standard specifications ■ Versatile for other fields *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

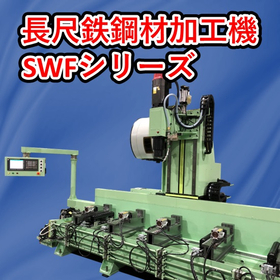

The "SWF Series" is used by companies that process and sell steel materials for building materials when they provide added value through processing. It is an NC long-length steel processing machine that maintains stable positioning accuracy over a long period, utilizing linear guides and ball screws on each axis, and the X-axis is equipped with a TCG runner (roller pinion rack). By using a frame structure and #45 linear guides, it enhances machine rigidity compared to the conventional SWS series, enabling quick acceleration and deceleration as well as high-torque processing. The dedicated conversational programming device reduces programming time, and since this program can be operated for a long time, cost-effectiveness can be expected. 【Features】 ■ "Easy Setup" with comprehensive standard equipment (clamps, work stoppers, tool length measurement device, grease lubrication device, coolant circulation device) ■ "Tool Change Anywhere" with ATC linked to the X-axis (time-saving through on-site tool changes) ■ "Easy Input" with long-length programming software "S-SYSTEM" *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a case study of a "5-axis mortising machine" manufactured for a building materials manufacturer. This is a dedicated machine for cutting the ends of large aluminum long materials. With its 5-axis head, it can perform 3D cutting operations. By equipping it with tools such as end mills, it can also perform hole drilling and milling on the workpiece ends. 【Case Overview】 ■ Application: 3D cutting of ends of residential and building materials ■ Industry: Building materials manufacturer *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is a gantry-type panel processing machine that moves on a track. Large: For workpieces larger than 5X10 (width over 1500mm, length over 3000mm) Medium: For workpieces larger than 4X8 (width over 1200mm, length 2400mm) Small: For workpieces of 3X6 (width 900mm, length 1800mm) Screw fastening: A dedicated machine for screwing into sheet materials This model is ideal for truck body construction and residential building materials (panel materials). The large series demonstrates its true value with insulated panels for trucks. Equipped with our original "Vertical and Horizontal Saw Unit," it consolidates the panel step cutting process, which traditionally required two steps (horizontal and vertical cutting) into one, significantly reducing takt time. The medium series accommodates various panels and features a spindle rotating head, enabling flexible angle cutting with a saw angle head. The small series also produces long vises in addition to workpiece suction, making it ideal for processes such as edge processing.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

<Optimal for wooden molds, foam molds, and trimming applications> The gantry-type 5-axis machining center [SWM5 series] features a compact, specially designed built-in spindle that allows the cutting tool to reach intricate areas. With a 3.7 kW spindle operating at 15,000 min-1, it powerfully processes materials such as wooden molds, resin, chemical wood, carbon, and FRP. Equipped with AI contour control 2 and tip point control, it enables simultaneous 5-axis machining, achieving smooth processing. 【Custom Orders from Sawai】 1. The specifications of the table can be customized to meet customer preferences. - T-slot table - Vacuum table - Tapping specifications, etc. 2. The table size can be tailored to customer requirements. - 2500mm x 1200mm (standard) - 4000mm x 2000mm (large order) - 1000mm x 1000mm (small order) *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company manufactures custom NC machine tools tailored to our customers' needs. First, we listen to what kind of machine the customer wants to create, then we create a conceptual design using 3D CAD and finalize the specifications. 【Examples of requests from customers】 - I want the stroke of each axis to be at the desired dimensions. (I want to create a machine that fits the workpiece) - I want to reduce costs without needing high precision or rigidity. (Cost reduction) - I want to increase the spindle speed. (Increase processing efficiency) - I want to increase the number of spindles. (Use a multi-head to improve production efficiency) - I want to increase the number of control axes. (Reduce setup time) - I want to install additional devices. (Mist prevention) - I want to change the number of ATC tools. (Increase efficiency) - I want to add a workpiece clamping device. (Such as vacuum clamps) - I want to change the position of the operation panel and control panel. (Improve operability) - I want to collect chips. (Environmental measures) - I want to add a dedicated screen to streamline programming and setup tasks. (Dedicated system) - I want to dock with the current equipment. (Inline) We will respond to various requests. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "SWS Series" is a processing machine that performs drilling, cutting, and other operations on various long materials, primarily focusing on long aluminum extrusions. The following models are available: - 6-axis turret type... capable of tool exchange using a 6-axis turret - ATC-equipped type... equipped with a BT40/3.7kw/10000min-1 spindle and either a 12-tool umbrella ATC or a 24-tool twin-arm ATC - SA type... SWS-SA type with angle cutting functionality All models are equipped with our original conversational programming system, the "S-SYSTEM," which simplifies the programming of processing procedures. Each axis is driven by ball screws and features three linear guides, achieving high rigidity and high precision. The linear guides use THK LM guides. **Features** - Industry-leading rapid feed speed and rigidity - All axes driven by ball screws - All models equipped with the original conversational "S-SYSTEM" - Automatic tool length measurement device included - Automatic centralized grease lubrication system included - Air clamp vice included - Work stopper included - Cutting oil system (oil mist) included *For more details, please download the PDF or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "SWR Series" adopts patented technology of a non-contact magnetic gear, allowing it to rotate the spindle at a maximum speed of 60,000 RPM, even though it uses bevel gears. Because it is non-contact, the heat from the spindle motor is less likely to transfer. This non-contact gear technology enables tool changes with a turret system for high-speed spindles, making the machine itself very compact. The tool change indexing speed is fast, allowing for tool changes in about 3 seconds on this NC high-speed router machining machine. Additionally, with FANUC AI contour control, we have achieved a reduction in shape errors at high feed rates. **Features** - Non-contact gears prevent heat from the spindle motor from transferring to the holder. - Non-contact gears eliminate vibrations caused by rotational transmission. - Non-contact gears allow for rotation at 60,000 RPM. - Six ATCs with a 6-axis turret eliminate the need to line up high-speed spindles. - Fast indexing speed. - Excellent dust collection capability does not hinder machining. *For more details, please download the PDF or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "SWM Series" is a three-axis gantry machining center that has received high praise in the wooden mold industry. The table moves back and forth, while the spindle moves left and right, as well as up and down, to perform machining operations. It is equipped with an automatic tool changer for automatic tool exchange. With an automatic tool length measurement device, there is no need to measure with a base master, providing a user-friendly feature. This is an NC model machining center that achieves smooth machining shapes with AI contour control I. Thanks to the FANUC spindle motor, it is capable of machining with stable torque from low to high speeds. Additionally, it uses high-rigidity precision linear guide ball screws, allowing for smooth axis movement. 【Features】 ■ Custom-made specifications available ■ Control unit: FANUC 0i-MF ■ All axes driven by ball screws ■ Automatic tool length measurement ■ Automatic centralized grease lubrication system *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration