- Publication year : 2024

46~90 item / All 108 items

Displayed results

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us Online46~90 item / All 108 items

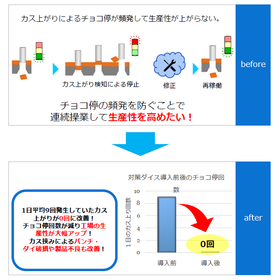

Introducing a case study using part processing technology with an accuracy of ±2μm achieved through the introduction of a new processing machine! * * At Nagumo Seisakusho, we improve productivity by preventing scrap accumulation through appropriate clearance settings, processing accuracy, and adjustment techniques, as well as reducing downtime. We addressed the challenges faced by automotive parts manufacturers who were struggling with frequent downtime due to scrap accumulation. We implemented measures against scrap accumulation for this manufacturer. The average occurrence of scrap accumulation, which was happening 9 times a day, was improved to 0 times, resulting in a reduction in downtime and a significant increase in factory productivity. 【Overview】 ■ Customer Industry: Automotive Parts Manufacturer ■ Inquiry Details: Frequent scrap accumulation during press processing, leading to machine stoppages and inefficiency ■ Proposed Solution: Recommendations for appropriate clearance and changes in part shape ■ Technology Used: Part processing with an accuracy of ±2μm achieved through the introduction of a new processing machine ■ Results: Increased productivity *For more details, please download the related catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Guaranteed shape measurement in the sub-micron order! We will provide quality assurance in line with the improvement of precision machining technology. We would like to introduce a case where we solved challenges by introducing a new machining center and wire electrical discharge machine to an automotive parts manufacturing company. The manufacturer was facing issues such as "although we produced punches and dies using three-dimensional machining to respond to the miniaturization and complexity of products, we could not create high-precision products," and "not only were defects occurring, but we could not adequately measure shapes with conventional measuring instruments, making it impossible to guarantee precision." In response, we ensured shape measurement that could not be measured with conventional contact-type tracers by using a laser microscope. [Overview] ■ Customer's industry: Automotive parts manufacturing ■ Machining technology: Parts can be processed with a precision of ±2μm using the new machining center and wire electrical discharge machine ■ Quality assurance: Introduced three-dimensional measuring instruments (Mitutoyo, OGP, TESA) and a laser microscope (KEYENCE) to guarantee shape measurement in the sub-micron order. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Introducing a case study using part processing technology with an accuracy of ±2μm achieved through the introduction of a new processing machine! * * At Nagumo Manufacturing, we improve productivity by preventing scrap accumulation through appropriate clearance settings, processing accuracy, and adjustment techniques, thereby reducing downtime. We solved the challenges faced by automotive parts manufacturers who were troubled by frequent downtime due to scrap accumulation, which hindered productivity. We implemented measures against scrap accumulation for this manufacturer. The average occurrence of scrap accumulation, which was happening 9 times a day, was improved to 0 times, resulting in a reduction in downtime and a significant increase in factory productivity. 【Overview】 ■ Customer Industry: Automotive parts manufacturing ■ Inquiry Details: Frequent scrap accumulation during press processing, causing machine stoppages and inefficiency ■ Proposed Solution: Recommendations for appropriate clearance and changes in part shape ■ Technology Used: Part processing with an accuracy of ±2μm achieved through the introduction of a new processing machine ■ Results: Increased productivity *For more details, please download the related catalog or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Specializing in sales types, we have a track record of producing over 10,000 molds! Contributing to improvements in quality and productivity by resolving technical issues! * * "I want to implement BCP measures by purchasing molds from two companies, could you provide some advice?" Recently, we received this kind of inquiry from a customer. Molds are often extremely important in factories where production would stop without them, so it is crucial to have multiple suppliers that can respond immediately when needed. "I could proceed with this design if I could make the part size 2mm smaller, but since the mold couldn't accommodate that, we had to make significant changes to the design, resulting in delays." I believe there are cases where the specifications of molds become a bottleneck for quality. I have heard that recently, some clients are requesting dual sourcing. At our company, a department specialized in technical development will do its utmost to address our customers' technical issues, so if anything resonates with you, please feel free to contact us. *For more details, please refer to the related materials or feel free to reach out to us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Examples of problem-solving such as precision mold design and manufacturing that reduced maintenance time! This document introduces case studies of precision mold design, manufacturing, and parts processing conducted by Nagumo Seisakusho Co., Ltd. It includes numerous case studies on precision mold design and manufacturing that reduced maintenance time, as well as precision mold parts processing that improved the lifespan of carbide punches. Additionally, we introduce our installed processing machines, including "high-precision profile grinding machines" and "high-precision vertical machining centers." If you are interested in the processing details or would like to discuss estimates, please feel free to contact us. [Contents] ■ Introduction of installed processing machines ■ Case studies of problem-solving in precision mold design and manufacturing ■ Case studies of problem-solving in precision mold parts processing *For more details, please refer to the related catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Guaranteed shape measurement in the sub-micron order! We will provide quality assurance in line with the improvement of precision machining technology. We would like to introduce a case where we solved challenges by introducing a new machining center and wire electrical discharge machine to an automotive parts manufacturing company. The manufacturer was struggling with the inability to produce high-precision products despite creating punches and dies through three-dimensional processing to accommodate the miniaturization and complexity of products. They faced issues not only with defects but also with the inability to adequately measure shapes with conventional measuring instruments, leading to a lack of precision assurance. To address this, we guaranteed shape measurement that could not be measured with traditional contact-type tracers by using a laser microscope. 【Overview】 ■ Customer's industry: Automotive parts manufacturing ■ Machining technology: Parts processing with a precision of ±2μm using a new machining center and wire electrical discharge machine ■ Quality assurance: Introduction of three-dimensional measuring instruments (Mitutoyo, OGP, TESA) and a laser microscope (KEYENCE) to guarantee shape measurement in the sub-micron order. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Introducing a case study using part processing technology with an accuracy of ±2μm achieved through the introduction of a new processing machine! * * At Nagumo Seisakusho, we improve productivity by preventing scrap accumulation through appropriate clearance settings, processing accuracy, and adjustment techniques, thereby reducing downtime. We addressed the challenges faced by automotive parts manufacturers who were struggling with frequent downtime due to scrap accumulation. We implemented measures against scrap accumulation for this manufacturer. The average occurrence of scrap accumulation, which was happening 9 times a day, was improved to 0, resulting in a reduction in downtime and a significant increase in factory productivity. 【Overview】 ■ Customer Industry: Automotive parts manufacturing ■ Inquiry Details: Frequent scrap accumulation during press processing, leading to machine stoppages and inefficiency ■ Proposed Solution: Recommendations for appropriate clearance and changes in part shape ■ Technology Used: Part processing with an accuracy of ±2μm achieved through the introduction of a new processing machine ■ Results: Increased productivity *For more details, please download the related catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Introducing various case studies on precision mold design and manufacturing that have reduced maintenance time! This document presents examples of precision mold design, manufacturing, and parts processing conducted by Nagumo Seisakusho Co., Ltd. It includes numerous case studies on challenges solved, such as precision mold design and manufacturing that reduced maintenance time, and precision mold parts processing that improved the lifespan of carbide punches. Additionally, we introduce our installed processing machines, including "high-precision profile grinding machines" and "high-precision vertical machining centers." If you are interested in processing details or quotes, please feel free to contact us. [Contents] ■ Introduction of installed processing machines ■ Case studies on challenges solved in precision mold design and manufacturing ■ Case studies on challenges solved in precision mold parts processing *For more details, please refer to the related catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Guaranteed submicron order shape measurement! We will provide quality assurance in line with the improvement of precision machining technology. We would like to introduce a case where a new machining center and wire electrical discharge machine were introduced to a manufacturer of automotive parts to solve challenges. The manufacturer was struggling with the inability to produce high-precision products despite creating punches and dies using three-dimensional processing to respond to the miniaturization and complexity of products. They faced issues not only with defects but also with the inability to adequately measure shapes with conventional measuring instruments, making it impossible to guarantee precision. To address this, we ensured shape measurement that could not be achieved with traditional contact-type tracers by using a laser microscope. [Overview] ■ Customer's industry: Manufacturer of automotive parts ■ Processing technology: Parts can be processed with an accuracy of ±2μm using the new machining center and wire electrical discharge machine ■ Quality assurance: Introduced three-dimensional measuring instruments (Mitutoyo, OGP, TESA) and a laser microscope (KEYENCE) to guarantee shape measurement in the submicron order. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Guaranteed shape measurement in the submicron order! We will provide quality assurance in line with the improvement of precision machining technology. We would like to introduce a case where a new machining center and wire electrical discharge machine were introduced to a manufacturer of automotive parts to solve their challenges. The manufacturer was struggling with the inability to produce highly accurate products despite creating punches and dies through three-dimensional processing to accommodate the miniaturization and complexity of products. They faced issues not only with defects but also with the inability to adequately measure shapes using conventional measuring instruments, which made it impossible to guarantee accuracy. To address this, we ensured shape measurement that could not be achieved with traditional contact-type tracers by using a laser microscope. 【Overview】 ■ Customer's industry: Manufacturer of automotive parts ■ Processing technology: Parts can be processed with an accuracy of ±2μm using the new machining center and wire electrical discharge machine ■ Quality assurance: Introduced three-dimensional measuring instruments (from Mitutoyo, OGP, TESA) and a laser microscope (from KEYENCE) to guarantee shape measurement in the submicron order. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Specializing in sales types with a track record of over 10,000 molds produced! Contributing to improvements in quality and productivity by resolving technical issues! * * "I want to purchase molds from two companies as a BCP measure, can you provide consultation?" Recently, we received this kind of inquiry from a customer. Molds are extremely important in factories where production would stop without them, so it is crucial to have multiple suppliers that can respond immediately when needed. "I could proceed with this design if I could make the part size 2mm smaller, but since the mold couldn't accommodate that, we had to make significant design changes and backtrack." I believe there are cases where mold specifications become a bottleneck in quality. I have heard that recently, some clients are requesting dual sourcing. At our company, a department specialized in technical development will do its utmost to address our customers' technical issues, so if anything resonates with you, please feel free to contact us. *For more details, please refer to the related materials or feel free to reach out to us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Introducing a case study using part processing technology with an accuracy of ±2μm achieved through the introduction of a new processing machine! At Nagumo Seisakusho, we improve productivity by preventing scrap accumulation through appropriate clearance settings, processing accuracy, and adjustment techniques, as well as reducing downtime. We addressed the challenges faced by automotive parts manufacturers who were struggling with frequent downtime due to scrap accumulation. We implemented measures against scrap accumulation for this manufacturer. The average occurrence of scrap accumulation, which was happening 9 times a day, was improved to 0, resulting in a reduction in downtime and a significant increase in factory productivity. 【Overview】 ■ Customer Industry: Automotive parts manufacturing ■ Inquiry Details: Frequent scrap accumulation during press processing, causing machine stoppages and inefficiency ■ Proposed Solution: Recommendations for appropriate clearance and changes in part shape ■ Technology Used: Part processing with an accuracy of ±2μm achieved through the introduction of a new processing machine ■ Results: Increased productivity *For more details, please download the related catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Introducing a case study using part processing technology with an accuracy of ±2μm achieved through the introduction of a new processing machine! * * At Nagumo Manufacturing, we are enhancing productivity by preventing scrap buildup through appropriate clearance settings, processing accuracy, and adjustment techniques, thereby reducing downtime. We addressed the challenges faced by automotive parts manufacturers who were struggling with frequent scrap buildup leading to production inefficiencies. Our company implemented measures against scrap buildup for this manufacturer. The average occurrence of scrap buildup, which was happening 9 times a day, was improved to 0, resulting in a reduction in downtime and a significant increase in factory productivity. 【Overview】 ■ Customer Industry: Automotive parts manufacturing ■ Inquiry Details: Frequent scrap buildup during press processing causing machine stoppages and inefficiencies ■ Proposed Solution: Recommendations for appropriate clearance and changes in part shape ■ Technology Used: Part processing with an accuracy of ±2μm achieved through the introduction of a new processing machine ■ Results: Increased productivity *For more details, please download the related catalog or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Eliminate burrs through mold manufacturing that meets the required values of the products sought by our customers! Introducing a case study from an electronic components manufacturer. When producing thin products, it is necessary to set an extremely narrow punch-die clearance, but it is difficult to reliably achieve the specified clearance in tolerance design. However, our company designs parts from the stage of design to achieve narrow clearances, allowing us to custom-manufacture both fabricated and purchased parts. As a result, we can manufacture molds that meet the required values of the products sought by our customers. [Case Overview] ■ Customer Industry: Electronic Components Manufacturer ■ Consultation Content: Desire to cut thin products sharply ■ Proposed Solution: Ultra-small clearance die ■ Technology Used: Improvement of mold structure and part precision ■ Outcome: Successfully eliminated previously unresolvable burrs. *For more details, please refer to the related materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Introducing numerous case studies on precision mold design and manufacturing that have reduced maintenance time! This document presents examples of precision mold design, manufacturing, and parts processing conducted by Nagumo Manufacturing Co., Ltd. It includes many case studies on precision mold design and manufacturing that have reduced maintenance time, as well as precision mold parts processing that has improved the lifespan of carbide punches. Additionally, we introduce our installed processing machines, including "high-precision profile grinding machines" and "high-precision vertical machining centers." If you are interested in processing details or quotes, please feel free to contact us. [Contents] ■ Introduction of installed processing machines ■ Case studies on challenges solved in precision mold design and manufacturing ■ Case studies on challenges solved in precision mold parts processing *For more details, please refer to the related catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

A 360-degree virtual factory tour is available through video! Feel free to explore the atmosphere and equipment of our company. Equipment and case study materials are also available! * * "Changing tomorrow with our dedicated molds" Every product from Nagumo Manufacturing is made to order! Do you have any issues with precision mold component processing or precision mold design? Our company has implemented a variety of equipment, allowing us to propose solutions from the customer's perspective for the problems they consult us about. This time, we have released a video that allows you to virtually tour our factory to introduce the scale of our operations, equipment, and qualifications. You can view everything from the entire factory to key equipment, processing areas, and inspection rooms in 360 degrees. Please watch the video from the related link! [Video Content] - Opening - Overview of the entire factory - Introduction of various equipment (machining centers, grinding machines, etc.) - Mold assembly and hand finishing - Introduction of the mold design room, engineering department, inspection room, and production management room - Other facility introductions Additionally, we are offering downloadable materials such as "Precision Mold Design and Manufacturing / Component Processing Case Studies" and "Equipment Materials." *For more details, feel free to check the "PDF Download."

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Specializing in sales types, we have a track record of producing over 10,000 molds! We contribute to improving quality and productivity by resolving technical issues! * * "I want to purchase molds from two companies as a BCP measure, can you provide consultation?" Recently, we received such an inquiry from a customer. Molds are extremely important in factories where production would stop without them, so it is crucial to have multiple suppliers that can respond immediately when needed. "I could proceed with this design if I could make the part size 2mm smaller, but since the mold couldn't accommodate it, we had to make significant changes to the design, causing delays." I believe there are cases where mold specifications become a bottleneck for quality. I have heard that recently, some clients are requesting dual sourcing. At our company, we have a department specialized in technical development that will do its utmost to address our customers' technical issues, so if anything resonates with you, please feel free to contact us. *For more details, please refer to the related materials or feel free to reach out to us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Introducing a case study using part processing technology with an accuracy of ±2μm achieved through the introduction of a new processing machine! * * At Nagumo Seisakusho, we improve productivity by preventing scrap accumulation through appropriate clearance settings, processing accuracy, and adjustment techniques, as well as reducing downtime. We addressed the challenges faced by automotive parts manufacturers who were struggling with frequent downtime due to scrap accumulation. Our company implemented measures against scrap accumulation for this manufacturer. The average occurrence of scrap accumulation, which was happening 9 times a day, was improved to 0, resulting in a reduction in downtime and a significant increase in factory productivity. 【Overview】 ■ Customer Industry: Automotive parts manufacturing ■ Consultation Details: Frequent scrap accumulation during press processing, leading to machine stoppages and inefficiency ■ Proposed Solution: Recommendations for appropriate clearance and changes in part shape ■ Technology Used: Part processing with an accuracy of ±2μm achieved through the introduction of a new processing machine ■ Results: Increased productivity *For more details, please download the related catalog or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Introducing various case studies on precision mold design and manufacturing that have reduced maintenance time! This document presents examples of precision mold design, manufacturing, and parts processing conducted by Nagumo Manufacturing Co., Ltd. It includes numerous case studies on challenges solved, such as precision mold design and manufacturing that reduced maintenance time, and precision mold parts processing that improved the lifespan of carbide punches. Additionally, we introduce our processing machines, including "high-precision profile grinding machines" and "high-precision vertical machining centers." If you are interested in our processing services or would like to request a quote, please feel free to contact us. [Contents] ■ Introduction of processing machines ■ Case studies on challenges solved in precision mold design and manufacturing ■ Case studies on challenges solved in precision mold parts processing *For more details, please refer to the related catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Eliminate burrs through mold manufacturing that meets the product requirements sought by customers! Introducing a case study from an electronic component manufacturer. When producing thin products, it is necessary to set an extremely narrow punch-die clearance, but achieving the specified clearance is difficult due to tolerance design. However, our company designs parts from the planning stage to realize narrow clearances, allowing us to custom-manufacture both fabricated and purchased components. As a result, we can produce molds that meet the product requirements sought by our customers. [Case Overview] ■ Customer Industry: Electronic Component Manufacturer ■ Inquiry Content: Desire to cut thin products sharply ■ Proposed Solution: Ultra-small clearance die ■ Technology Used: Improvement of mold structure and component precision ■ Outcome: Successfully eliminated previously unresolved burrs *For more details, please refer to the related materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Introducing a case study using part processing technology with an accuracy of ±2μm achieved through the introduction of a new processing machine! * * At Nagumo Seisakusho, we improve productivity by preventing scrap accumulation through appropriate clearance settings, processing accuracy, and adjustment techniques, thereby reducing downtime. We addressed the challenges faced by automotive parts manufacturers who were struggling with frequent downtime due to scrap accumulation. Our company implemented measures against scrap accumulation for this manufacturer. The average occurrence of scrap accumulation, which was happening 9 times a day, was improved to 0, resulting in a reduction in downtime and a significant increase in factory productivity. 【Overview】 ■ Customer Industry: Automotive parts manufacturing ■ Inquiry Details: Frequent scrap accumulation during press processing, causing machine stoppages and inefficiency ■ Proposed Solution: Recommendations for appropriate clearance and changes in part shape ■ Technology Used: Part processing with an accuracy of ±2μm achieved through the introduction of a new processing machine ■ Results: Increased productivity *For more details, please download the related catalog or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Guaranteed submicron order shape measurement! We will provide quality assurance in line with the improvement of precision processing technology. We would like to introduce a case where a new machining center and wire electrical discharge machine were introduced to a manufacturer of automotive parts, solving their challenges. The manufacturer was struggling with the inability to produce high-precision products despite creating punches and dies through three-dimensional processing to meet the demands for miniaturization and complex shapes. They faced issues not only with defects but also with the inability of conventional measuring instruments to adequately measure shapes, leading to a lack of precision assurance. To address this, we guaranteed shape measurement that could not be achieved with traditional contact-type tracers by using a laser microscope. 【Overview】 ■ Customer's industry: Automotive parts manufacturing ■ Processing technology: Parts processing with a precision of ±2μm using the new machining center and wire electrical discharge machine ■ Quality assurance: Introduction of three-dimensional measuring instruments (Mitutoyo, OGP, TESA) and a laser microscope (KEYENCE), guaranteeing shape measurement in the submicron order. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Specializing in sales types, we have a track record of over 10,000 molds produced! Contributing to improvements in quality and productivity by resolving technical issues! * * "I want to purchase molds from two companies as a BCP measure, could you provide some consultation?" Recently, we received this kind of inquiry from a customer. Molds are often extremely important in factories where production would stop without them, so it is crucial to have multiple suppliers that can respond immediately when needed. "There was a situation where if we could reduce the part size by another 2mm, we could proceed with this design, but since the mold couldn't accommodate it, we had to make significant changes to the design, resulting in a setback." I believe there are cases where the specifications of molds become a bottleneck in quality. I have heard that recently, some clients are requesting dual sourcing. Our company has a department specialized in technical development that will do its utmost to address your technical issues, so if anything resonates with you, please feel free to contact us. *For more details, please refer to the related materials or feel free to reach out to us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

A 360-degree virtual factory tour is available in the video! Feel free to explore the atmosphere and facilities of our company. Equipment and case study materials are also available! * * "Changing tomorrow with our dedicated molds" Every product from Nagumo Manufacturing is custom-made! Do you have any issues with precision mold component processing or precision mold design? Our company has introduced a variety of equipment, and we can provide proposals from the customer's perspective for the problems you consult us about. This time, we would like to introduce the scale of our factory, our equipment, and our qualifications, and we have released a video that allows you to take a virtual tour of our company. You can view everything from the entire factory to key equipment, processing sites, and inspection rooms in 360 degrees. Please watch the video from the related link! [Video Content] - Opening - Overview of the entire factory - Introduction of various equipment (machining centers, grinding machines, etc.) - Mold assembly and hand finishing - Introduction of the mold design room, engineering department, inspection room, and production management room - Other facility introductions Additionally, we are offering downloadable materials such as "Precision Mold Design and Manufacturing / Component Processing Case Studies" and "Equipment Materials." *For more details, feel free to check the "PDF Download."

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Guaranteed shape measurement in the sub-micron order! We will provide quality assurance in line with improvements in precision machining technology. We would like to introduce a case where a manufacturer of automotive parts solved challenges by introducing a new machining center and wire electrical discharge machine. The manufacturer was facing issues such as "despite producing punches and dies with three-dimensional machining to accommodate the miniaturization and complexity of products, they could not create high-precision products" and "not only were defects occurring, but the conventional measuring instruments were insufficient for shape measurement, making it impossible to guarantee accuracy." In response, we ensured shape measurement that could not be achieved with traditional contact-type tracers by using a laser microscope. 【Overview】 ■ Customer's industry: Manufacturer of automotive parts ■ Machining technology: Parts can be processed with an accuracy of ±2μm using the new machining center and wire electrical discharge machine ■ Quality assurance: Introduced three-dimensional measuring instruments (Mitutoyo, OGP, TESA) and a laser microscope (KEYENCE), guaranteeing shape measurement in the sub-micron order. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Introducing a case study using part processing technology with an accuracy of ±2μm achieved through the introduction of a new processing machine! * * At Nagumo Manufacturing, we improve productivity by preventing scrap accumulation through appropriate clearance settings, processing accuracy, and adjustment techniques, thereby reducing downtime. We addressed the challenges faced by automotive parts manufacturers who were struggling with frequent downtime caused by scrap accumulation, which hindered productivity. We implemented measures against scrap accumulation for this manufacturer. The average occurrence of scrap accumulation, which was happening 9 times a day, was improved to 0, resulting in a reduction in downtime and a significant increase in factory productivity. 【Overview】 ■ Customer Industry: Automotive parts manufacturing ■ Consultation Details: Frequent scrap accumulation during press processing, causing machine stoppages and inefficiency ■ Proposed Solution: Recommendations for appropriate clearance and changes in part shape ■ Technology Used: Part processing with an accuracy of ±2μm achieved through the introduction of a new processing machine ■ Results: Increased productivity *For more details, please download the related catalog or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Eliminate burrs through mold manufacturing that meets the product requirements sought by customers! Introducing a case study from an electronic component manufacturer. When producing thin products, it is necessary to set an extremely narrow punch-die clearance, but achieving the specified clearance is difficult due to tolerance design. However, our company designs parts from the planning stage to achieve narrow clearances, allowing us to custom-manufacture both fabricated and purchased components. As a result, we can manufacture molds that meet the product requirements sought by our customers. [Case Overview] ■ Customer Industry: Electronic Component Manufacturer ■ Inquiry Details: Desire to cut thin products sharply ■ Proposed Solution: Die with ultra-small clearance ■ Technology Used: Improvement of mold structure and component precision ■ Outcome: Successfully eliminated previously unresolved burrs *For more details, please refer to the related materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Introducing examples of problem-solving such as precision mold design and manufacturing that reduce maintenance time! This document presents case studies of precision mold design, manufacturing, and parts processing conducted by Nagumo Seisakusho Co., Ltd. It includes numerous case studies on precision mold design and manufacturing that reduced maintenance time, as well as precision mold parts processing that improved the lifespan of carbide punches. Additionally, we introduce our installed processing machines, including "high-precision profile grinding machines" and "high-precision vertical machining centers." If you are interested in processing details or would like to request a quote, please feel free to contact us. 【Contents】 ■ Introduction of installed processing machines ■ Case studies of problem-solving in precision mold design and manufacturing ■ Case studies of problem-solving in precision mold parts processing *For more details, please refer to the related catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Guaranteed shape measurement in the sub-micron order! We will provide quality assurance in line with the improvement of precision machining technology. We would like to introduce a case where we solved challenges by introducing a new machining center and wire electrical discharge machine to an automotive parts manufacturing company. The manufacturer was struggling with issues such as "although we produced punches and dies using three-dimensional machining to respond to the miniaturization and complexity of products, we could not create high-precision products," and "not only were defects occurring, but we could not adequately measure shapes with conventional measuring instruments, making it impossible to guarantee precision." Therefore, we ensured shape measurement that could not be measured with conventional contact-type tracers by using a laser microscope. 【Overview】 ■ Customer's industry: Automotive parts manufacturing ■ Machining technology: Parts can be processed with a precision of ±2μm using the new machining center and wire electrical discharge machine ■ Quality assurance: Introduced three-dimensional measuring instruments (from Mitutoyo, OGP, TESA) and a laser microscope (from KEYENCE) to guarantee shape measurement in the sub-micron order. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Specializing in sales types, we have a track record of producing over 10,000 molds! Contributing to improvements in quality and productivity by resolving technical issues! * * "I want to purchase molds from two companies as a BCP measure, can you provide consultation?" Recently, we received such an inquiry from a customer. Molds are extremely important in factories where production would stop without them, so it is crucial to have multiple suppliers that can respond immediately when needed. "I could proceed with this design if I could reduce the part size by another 2mm, but since the mold couldn't accommodate it, we had to make significant changes to the design, causing delays." I believe there are cases where the specifications of the mold become a bottleneck in quality. I have heard that recently, some clients are requesting dual sourcing. Our company has a department specialized in technical development that will do its utmost to address your technical issues, so if anything resonates with you, please feel free to contact us. *For more details, please refer to the related materials or feel free to reach out to us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Introducing a case study using part processing technology with an accuracy of ±2μm achieved through the introduction of a new processing machine! * * At Nagumo Manufacturing, we enhance productivity by preventing scrap accumulation through appropriate clearance settings, processing accuracy, and adjustment techniques, thereby reducing downtime. We addressed the challenges faced by automotive parts manufacturers who were struggling with frequent downtime due to scrap accumulation. Our company implemented measures against scrap accumulation for this manufacturer. The average occurrence of scrap accumulation, which was happening 9 times a day, was improved to 0, resulting in a reduction in downtime and a significant increase in factory productivity. 【Overview】 ■ Customer Industry: Automotive parts manufacturing ■ Consultation Details: Frequent scrap accumulation during press processing, causing machine stoppages and inefficiency ■ Proposed Solution: Recommendations for appropriate clearance and changes in part shape ■ Technology Used: Part processing with an accuracy of ±2μm achieved through the introduction of a new processing machine ■ Results: Increased productivity *For more details, please download the related catalog or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The milling processing technology for carbide materials has tripled the lifespan of punches! Here is a case study for a precision electronic component manufacturer. When performing electrical discharge machining on carbide materials, microcracks due to thermal effects occur during processing. These cracks penetrate to a depth of about 20μm, so no matter how much you polish the surface, they remain. These cracks can cause wear in punches that are subjected to strong loads. In contrast, milling processing does not produce any microcracks at all. Milling tools can go down to R0.1, and the flexibility of the processing shape is very high. [Case Overview] - Customer Industry: Precision Electronic Component Manufacturer - Inquiry: Wanted to improve the lifespan of carbide riveting punches - Proposed Solution: Transitioning from electrical discharge machining to milling - Technology Used: Milling processing technology for carbide materials - Results: The lifespan of the punches has tripled. *For more details, please refer to the PDF document or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The lifespan of punches has tripled thanks to milling technology for hard materials! Here’s a case study for a precision electronic components manufacturer. When processing hard materials with electrical discharge machining, micro-cracks caused by heat during machining occur. These cracks penetrate to a depth of about 20μm, and no matter how much you polish to achieve a smooth surface, they remain. These cracks can lead to wear in punches that are subjected to high loads. In contrast, milling does not produce any micro-cracks at all. Milling tools can go down to R0.1, providing a high degree of flexibility in machining shapes. [Case Overview] - Customer Industry: Precision electronic components manufacturer - Inquiry: Wanted to improve the lifespan of hard material riveting punches - Proposed Solution: Transition from electrical discharge machining to milling - Technology Used: Milling technology for hard materials - Results: The lifespan of the punches has tripled *For more details, please refer to the PDF document or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

You can take a 360-degree virtual factory tour through a video! Feel free to explore the atmosphere and equipment within the company. Equipment and case study materials are also available! * * "Changing Tomorrow with Our Dedicated Molds" Every product from Nagumo Manufacturing is custom-made! Do you have any issues with precision mold parts processing or precision mold design? Our company has implemented a wide range of equipment, allowing us to propose solutions from the customer's perspective for any problems they may have. This time, we would like to introduce the scale of our factory, our equipment, and our qualifications, and we have released a video that allows you to take a virtual tour of our company. You can view everything from the entire factory to key equipment, processing areas, and inspection rooms in 360 degrees. Please watch the video from the related link! [Video Content] - Opening - Introduction of the entire factory - Introduction of various equipment (machining centers, grinding machines, etc.) - Mold assembly and hand finishing - Introduction of the mold design room, technical department, inspection room, and production management room - Other facility introductions Additionally, we are offering downloadable materials such as "Precision Mold Design and Manufacturing / Parts Processing Case Studies" and "Equipment Materials." *For more details, feel free to check the "PDF Download."

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a case study using a part processing technology with an accuracy of ±2μm achieved through the introduction of a new processing machine! * * At Nagumo Manufacturing, we are improving productivity by preventing scrap accumulation through appropriate clearance settings, processing accuracy, and adjustment techniques, as well as reducing downtime. We addressed the challenges faced by automotive parts manufacturers who were struggling with frequent downtime due to scrap accumulation. Our company implemented measures against scrap accumulation for this manufacturer. The average occurrence of scrap accumulation, which was happening 9 times a day, was improved to 0, resulting in a reduction in downtime and a significant increase in factory productivity. 【Overview】 ■ Customer Industry: Automotive parts manufacturing ■ Consultation Content: Frequent scrap accumulation during press processing, leading to machine stoppages and inefficiency ■ Proposed Solution: Recommendations for appropriate clearance and changes in part shape ■ Technology Used: Part processing with an accuracy of ±2μm achieved through the introduction of a new processing machine ■ Results: Increased productivity *For more details, please download the related catalog or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Guaranteed shape measurement in the sub-micron order! We will provide quality assurance in line with the improvement of precision machining technology. We would like to introduce a case where we solved challenges by introducing a new machining center and wire EDM machine to an automotive parts manufacturing company. The manufacturer was facing issues such as, "Although we produced punches and dies using three-dimensional machining to respond to the miniaturization and complexity of products, we could not create high-precision products," and "Not only were defects occurring, but we could not adequately measure shapes with conventional measuring machines, making it impossible to guarantee precision." Therefore, we ensured shape measurement that could not be measured with conventional contact-type tracers by using a laser microscope. 【Overview】 ■ Customer's industry: Automotive parts manufacturing ■ Machining technology: Parts can be processed with a precision of ±2μm using the new machining center and wire EDM machine ■ Quality assurance: Introduced three-dimensional measuring instruments (Mitutoyo, OGP, TESA) and a laser microscope (KEYENCE) to guarantee shape measurement in the sub-micron order. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Nagumo Manufacturing Co., Ltd., we have introduced a "High-Precision Wire Electrical Discharge Machine." It is one of the largest sizes among wire electrical discharge machines manufactured by Seibu Electric. The processing fluid is water-based, and it uses φ0.2 wire. We specialize in processing mold plates, achieving a pitch accuracy of 0.001mm or better with the high machine precision characteristic of Seibu Electric and temperature control close to that of a constant temperature room. 【Machine Information】 ■ Manufacturer: Seibu Electric Co., Ltd. ■ Machine Type: High-Precision Wire Electrical Discharge Machine ■ Model: SuperMM80B ■ Axis Movement: x800 y600 z230 ■ Installation Date: August 2021 Related materials provide details about the wire processing machine, as well as other processing machines and case studies.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Specializing in sales types, we have a track record of producing over 10,000 molds! Contributing to improvements in quality and productivity by resolving technical issues! * * "I want to purchase molds from two companies as a BCP measure, could you provide some consultation?" Recently, we received such an inquiry from a customer. Molds are extremely important in factories, often being critical to production; therefore, it is essential to have multiple suppliers that can respond immediately when needed. "There was a situation where if we could reduce the part size by another 2mm, we could proceed with this design, but since the mold couldn't accommodate it, we had to make significant changes to the design, causing delays." I believe there are cases where the specifications of molds become a bottleneck in quality. Recently, I have heard that some clients are requesting dual sourcing for molds. Our company has a department specialized in technical development that will do its utmost to address our customers' technical issues, so if anything resonates with you, please feel free to contact us. *For more details, please refer to the related materials or feel free to reach out to us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Nagumo Manufacturing has an official Instagram! We regularly share our daily activities at Nagumo Manufacturing and information related to molds. ↓↓↓ You can check it out at the URL below. ↓↓↓ https://instagram.com/nagumo.ss?igshid=YmMyMTA2M2Y= You can also contact us via DM on Instagram, so feel free to reach out!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Examples of problem-solving such as precision mold design and manufacturing that reduced maintenance time! This document introduces case studies of precision mold design, manufacturing, and parts processing conducted by Nagumo Seisakusho Co., Ltd. It includes numerous case studies on precision mold design and manufacturing that reduced maintenance time, as well as precision mold parts processing that improved the lifespan of carbide punches. Additionally, we introduce the processing machines we have implemented, including "high-precision profile grinding machines" and "high-precision vertical machining centers." If you are interested in the processing details or would like to discuss estimates, please feel free to contact us. [Contents] ■ Introduction of implemented processing machines ■ Case studies of problem-solving in precision mold design and manufacturing ■ Case studies of problem-solving in precision mold parts processing *For more details, please refer to the related catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Eliminate burrs through mold manufacturing that meets the product requirements sought by customers! Introducing a case study from an electronic components manufacturer. When producing thin products, it is necessary to set an extremely narrow punch-die clearance, but achieving the specified clearance is difficult due to tolerance design. However, our company designs parts from the planning stage to achieve narrow clearances, allowing us to custom-manufacture both produced and purchased parts. As a result, we can manufacture molds that meet the product requirements sought by customers. [Case Overview] ■ Customer Industry: Electronic Components Manufacturer ■ Consultation Content: Desire to cut thin products sharply ■ Proposed Solution: Ultra-small clearance die ■ Technology Used: Improvement of mold structure and part precision ■ Outcome: Successfully eliminated previously unresolvable burrs *For more details, please refer to the related materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Introducing a case study using part processing technology with an accuracy of ±2μm achieved through the introduction of a new processing machine! * * At Nagumo Seisakusho, we improve productivity by preventing scrap buildup through appropriate clearance settings, processing accuracy, and adjustment techniques, thereby reducing downtime. We addressed the challenges faced by automotive parts manufacturers who were troubled by frequent downtime due to scrap buildup, which hindered productivity. We implemented measures against scrap buildup for this manufacturer. The average occurrence of scrap buildup, which was happening 9 times a day, was improved to 0, resulting in a reduction in downtime and a significant increase in factory productivity. 【Overview】 ■ Customer Industry: Automotive parts manufacturing ■ Inquiry Details: Frequent scrap buildup during press processing, causing machine stoppages and inefficiency ■ Proposed Solution: Recommendations for appropriate clearance and changes in part shape ■ Technology Used: Part processing with an accuracy of ±2μm achieved through the introduction of a new processing machine ■ Results: Increased productivity *For more details, please download the related catalog or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Achieve smooth and highly responsive machining! We introduce our machining equipment, the "High-Precision Profile Grinding Machine / CAM Image Profile Grinding Machine." The "High-Precision Profile Grinding Machine" employs a linear motor for the lifting axis, enabling smooth and highly responsive machining. The "CAM Image Profile Grinding Machine" is equipped with a high-magnification CCD camera with zoom capabilities of 80x, 125x, 250x, and 500x. At 500x magnification, it is possible to position and measure the accuracy of the workpiece with a precision of 0.5 microns. 【Features of the High-Precision Profile Grinding Machine】 ■ Linear motor used for the lifting axis ■ Achieves smooth and highly responsive machining ■ Standard equipped with a new type of LED transmitted lighting, making the projected image very clear ■ Capable of wide-ranging and high-precision contour grinding *Additional machining equipment and case studies for problem-solving can be viewed in the PDF materials.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The lifespan of punches has tripled thanks to milling technology for hard materials! Here we present a case study for a precision electronic components manufacturer. When processing hard materials using electrical discharge machining, micro-cracks occur due to heat during the machining process. These cracks penetrate to a depth of about 20μm, and no matter how much you polish the surface, they remain. These cracks can cause wear in punches that are subjected to strong loads. In contrast, milling does not produce any micro-cracks at all. Milling tools can go down to R0.1, offering very high flexibility in machining shapes. [Case Overview] - Customer Industry: Precision electronic components manufacturer - Inquiry: We want to improve the lifespan of hard carbide riveting punches. - Proposed Solution: Transition from electrical discharge machining to milling. - Technology Used: Milling technology for hard materials. - Results: The lifespan of the punches has tripled. *For more details, please refer to the PDF document or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Achieving reduced maintenance time and improved product quality with highly reproducible molds! Introducing a case study of problem-solving for a film processing manufacturer. The customer, a film processing manufacturer, faced issues where the condition of the products changed with each mold maintenance, affecting quality, and it took time to adjust the molds. In response, we proposed solutions such as high precision of parts and high precision in alignment. Through our high-precision processing and assembly adjustment technology, we created highly reproducible molds, leading to reduced maintenance time and improved product quality, resulting in cost reduction. 【Case Study】 ■ Customer's Industry: Film Processing Manufacturer ■ Consultation Details: - Product condition changes with each mold maintenance, affecting quality - Time-consuming mold adjustments ■ Proposed Solutions: High precision of parts and high precision in alignment ■ Technologies Used: High-precision parts processing and mold alignment technology ■ Results: - Improved product quality - Reduced mold adjustment time *Additional case studies and available processing machines can be found in the related catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration