1~27 item / All 27 items

Displayed results

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us Online1~27 item / All 27 items

The customer suddenly requested that we take measures to address carbon neutrality as instructed by the parent company. We were conducting routine inspections of the mechanical power meters at multiple factory buildings, but due to a shortage of manpower, we were unable to meet the parent company's required standards. Therefore, we were in need of a systematic approach to power monitoring. In response, we proposed the "LoRa wireless device." For this power monitoring, using the Hakaru Plus power converter (TWPM) allows for complete retrofitting installation at the desired monitoring locations. [Case Overview] ■ Issues - Instructions for carbon neutrality measures from the parent company - Need for systematic power monitoring ■ Request: A good system that can operate wirelessly ■ Proposal: LoRa wireless device *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the customer's factory, there are three boiler facilities, and abnormalities are confirmed through daily patrol inspections. However, the locations of the boiler facilities are far away and very difficult to access. The office cannot detect abnormalities, and the patrol inspections are often delayed in noticing them, so there was a request to be aware of and respond to abnormalities as they occur. Therefore, we proposed the "LoRa wireless device," which enables wireless transmission of contact signals. This allows the abnormal signals from the scattered equipment to be checked in the office, eliminating the need for patrol inspections solely to confirm the presence of abnormalities. [Case Overview] ■ Issues - The boiler facilities are located far away and are very difficult to access. - The office cannot detect abnormalities, and patrol inspections are often delayed in noticing them. ■ Request: To be aware of and respond to abnormalities as they occur. ■ Proposal: LoRa wireless device. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The customer conducts daily inspections of the liquid flow in five scattered pipes within the factory, but they were considering how to visualize this in the office. They wanted to detect any irregularities in the flow in advance, but were troubled by the high costs associated with wiring work. Therefore, we proposed the "LoRa wireless device," which enables the wireless transmission of analog signals. The analog contact signals from the flow meters installed in the five pipes are input to the "HLR-A1" and transmitted via wireless to the office's "HLR-A8-OUT." This allows for real-time monitoring on the digital panel meter in the office. [Case Overview] ■ Issues - Visualizing the liquid flow in five scattered pipes within the factory in the office - Wanting to detect any irregularities in the flow in advance ■ Request: To transmit data wirelessly to the office and know the flow in real-time ■ Proposal: LoRa wireless device *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The customer has decided to enhance the efficiency of responding to abnormal data collection as part of the factory's digital transformation. They expressed a desire to monitor the frequency and occurrence time of abnormal trends, prioritize responses to abnormalities, and improve efficiency. However, they were concerned about the high costs of wiring abnormal signals from each control panel to the office. Therefore, we proposed our 'LoRa wireless device.' This allows for monitoring abnormal trends without any additional wiring work. Additionally, by wiring lamps and buzzers to the IoT gateway in the office, they can be immediately notified of any abnormalities, and notifications can also be sent via email. [Case Overview] ■ Issues - Monitoring the frequency and occurrence time of abnormal trends - Prioritizing responses to abnormalities for efficiency ■ Request: Automatically collect abnormal signals wirelessly for easy monitoring and management ■ Proposal: LoRa wireless device *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

There was a leakage current in the factory, and when the leakage breaker tripped, it affected production and could potentially lead to serious accidents, which was a concern for the customer. To identify the timing of the occasional leakage, they consulted us about automatically collecting leakage current data and pinpointing the final leakage location. In response, we proposed the electronic multimeter 'XM2-110'. By installing the multimeter on the target power lines (single-phase three-wire and three-phase three-wire) and connecting it to a LoRa wireless device, there is no need for wiring work to the office, and it is possible to automatically collect and notify leakage current data beyond just power elements. [Case Overview] ■ Issues - Understanding the timing of occasional leakage - Identifying the source of the leakage ■ Request: Automatically collect leakage current data and identify the final leakage location ■ Proposal: LoRa wireless device, electronic multimeter *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The customer has identified the visualization and reporting of CO2 emissions as a challenge in their carbon neutral initiatives, and they expressed a desire to increase the number of monitoring points for electricity monitoring in detail. However, they were concerned that retrofitting a system would lead to enormous costs for wiring and system expenses, especially as the number of points increased. In response, we proposed the "Electric Power Converter TWPM" and "LoRa Wireless Device." Since the electric power data can be output as CSV from the office PC, the customer can apply coefficients to convert it into CO2 emissions. [Case Overview] ■ Challenges - Visualization and reporting of CO2 emissions as part of carbon neutral initiatives - Detailed increase in monitoring points for electricity monitoring ■ Request: A system that can easily establish wireless electricity monitoring ■ Proposal: LoRa Wireless Device, TWPM *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The customer's logistics warehouse has a lot of cargo stored in refrigerators and freezers, and they inquired about the power usage when the refrigerators are full versus when they are nearly empty. Since they are not currently monitoring power usage, they would like to visualize the power consumption by time period to understand the current situation. Therefore, we propose our "Power Consumption Converter TWPM" and "LoRa Wireless Device." The power supply for a total of 17 refrigeration and freezing units is consolidated in the power distribution panel, allowing for system construction with installation work only within the panel. [Case Overview] ■ Issue - Understanding the power usage when the refrigerator is full versus when it is nearly empty ■ Request: Visualizing power usage by time period to understand the current situation ■ Proposal: LoRa Wireless Device, TWPM *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The customer was responsible for the accounting of a ready-mixed concrete factory and was troubled by not knowing many things, such as the monthly electricity costs, how much power was consumed by the operation of each piece of equipment, and which equipment's operation could be reduced to lower electricity costs. Since it was the first time monitoring electricity at a ready-mixed concrete factory, we visited with a technician from our instrumentation department. We installed the demand monitoring device "CSA-109-T" and the demand display unit "CSA-109-D2," allowing them to check the real-time power usage. Afterward, we proposed a method to automate power monitoring for each piece of equipment by installing "LoRa wireless devices" and "TWPM." [Case Overview] ■ Issues - How much power is consumed by the operation of each piece of equipment? - Which equipment's operation can be reduced to lower electricity costs? ■ Proposal: LoRa wireless devices, TWPM *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"Our company policy requires that we cannot adopt systems that do not use the cloud." "Do you have concerns such as wanting to start data collection with a small scale?" With the 'LoRa wireless device' specialized for data collection and visualization, it is possible to achieve factory DX, IoT implementation on-site, and efficiency in inspection tasks. Even when placed inside a control panel, it can communicate over a distance of 1.5 km without the need for wiring work, making it low-cost. 【Features】 ■ Can communicate over a distance of 1.5 km even when placed inside a control panel ■ Low cost with no wiring work required ■ Small start possible from a single measurement point ■ Monthly usage fee of 0 yen, does not use the cloud ■ Since the system is completed locally, the only necessary cost is the equipment cost *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The customer has introduced Keyence's clamp-on flow meters at their factory and conducts numerical checks twice a day during morning and afternoon patrol inspections. The flow meters are located in four places far from the office, making it very labor-intensive and inefficient to check them every day. They wanted to implement automatic data collection for efficiency, but were concerned about the high costs of wired installation. Therefore, we proposed the "LoRa wireless device." This eliminated the need for patrol inspections of the four flow meters located far apart, and also removed the need for wiring work between the site and the office, allowing for a cost-effective installation. 【Case Overview】 ■ Issues - The flow meters being inspected are located far from the office in four places, making it labor-intensive and inefficient. - They want to implement automatic data collection, but wired installation costs are high. ■ Request: A wireless data collection system that does not require wiring work and can be easily retrofitted. ■ Proposal: LoRa wireless device. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The customer manually measures the pH concentration of the factory's water reservoir three times a day to check if there are any issues. They were considering automating the collection of pH concentration data and storing it as evidence data, but since the reservoir is located at the edge of the factory, the cost of wiring work would be high, making the implementation challenging. In response, our company proposed the "HLR-A4C4 (multi-functional model)" for the on-site "LoRa wireless device," anticipating that in the future, flow pulses could be input and wireless communication could be established for the water channel. By using this wireless device, wiring work between the reservoir and the control panel room is no longer necessary, allowing for easy transfer of pH data to the central monitoring device. [Case Overview] ■ Issues - Manual measurement is cumbersome and inefficient - Desire to automatically collect pH concentration data and store/manage it as evidence data - High implementation barriers due to the cost of wiring work ■ Request: Transfer pH data to the central monitoring device ■ Proposal: LoRa wireless device *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The customer was implementing energy-saving measures that could be done at welfare facilities, such as reviewing air conditioning temperature settings and gradually turning off lights, but they were struggling to reduce electricity costs. They consulted us, saying, "We want to introduce a system that minimizes installation costs and leads to energy savings and reduced electricity usage year after year. Is there a good method for this?" Our company proposed the 'LoRa wireless device,' which does not require wiring work to reduce installation costs. By linking the demand monitoring device with the air conditioning control device, we made it possible to reduce contracted power year after year, thereby lowering electricity costs without conscious effort. [Case Overview] ■ Issues - Energy-saving measures that can be implemented at welfare facilities - High electricity costs during summer and winter when using air conditioning ■ Request: To minimize installation costs and introduce a system that leads to energy savings and reduced electricity usage year after year ■ Proposal: LoRa wireless device *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In a certain town, there are 20 drainage control panels scattered around, and the customer was conducting daily inspections of these panels from the purification center, checking the pump load current and any abnormal occurrences. They wanted to consolidate the information from the 20 drainage control panels and automatically collect data at the purification center, but they were troubled by the fact that wiring work was impossible due to the distance of the 20 panels being within a 2 km radius. Our company proposed "LoRa wireless" technology and implemented simple construction by retrofitting equipment into the existing control panels. Although there were some communication difficulties, installing a relay (HLR-RPT) stabilized the communication. [Case Overview] ■ Issues - Spending half a day every day on inspections and wasting gasoline due to driving around - Wiring work was impossible due to the distance of the 20 control panels being within a 2 km radius ■ Request: Wireless data collection ■ Proposal: LoRa wireless devices *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

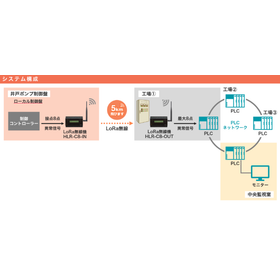

In your factory, you use well water for water treatment, but since the well is located far from the factory, you check and monitor the condition of the well pump control panel daily. You want to improve the efficiency of daily inspection tasks and continuously monitor the condition, but since the control panel is local, it is necessary to wire for abnormal signal transmission, which is physically impossible. You were troubled by the need to transmit abnormal signals wirelessly without wiring. Therefore, we propose the "LoRa wireless device." With long-distance communication up to 5 km in line of sight, it can wirelessly transmit signals without the need for wiring, making it perfect for wireless communication of various status signals from the local control panel. [Case Overview] ■ Issues - If inspections are neglected, water will not come to the factory - Want to improve efficiency and continuously monitor the condition - Wiring is necessary but physically impossible ■ Request: Wireless transmission of abnormal signals without wiring ■ Proposal: LoRa wireless device *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The customer received instructions from top management to implement decarbonization measures and expressed a desire to start by understanding the current situation, specifically by monitoring the power consumption of four compressors that are likely to have high electricity usage in the factory. However, the four compressors are scattered throughout the factory, making it difficult to accurately assess power consumption through routine inspections. Additionally, they wanted to automatically collect power consumption data, but were struggling with the complexity of wiring work. In response, we proposed the "LoRa wireless device." This device can be retrofitted to the measurement points, allowing for monitoring and data collection of all power element data from the measurement points at the office via wireless communication. [Case Overview] ■ Issues - Implementation of decarbonization measures - Monitoring of compressor power consumption - Inability to accurately assess power consumption through routine inspections ■ Request: Easy retrofitting to measurement points and monitoring via wireless communication from the office ■ Proposal: LoRa wireless device *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The customer needed to change their electricity provider due to the bankruptcy of a new power company. Calculating the costs, it would result in an annual increase of 8 million yen in electricity bills compared to before, prompting them to consider the introduction of a demand monitoring device to further promote energy conservation. However, they faced difficulties as the wiring work from the school's power receiving equipment to the office could not secure a wiring route, and undertaking the construction would incur significant costs. Therefore, we proposed the construction of a system using our "Demand Monitoring System" with 'LoRa wireless' communication capable of reaching 5 km. There are no monthly system usage fees, and it can be implemented with just the cost of the equipment. 【Case Overview】 ■ Issues - The new power company went bankrupt, necessitating a change of electricity provider. - Wiring work from the school's power receiving equipment to the office cannot secure a wiring route. - Undertaking construction would incur significant costs. ■ Request: To easily retrofit the power receiving equipment and use wireless communication for demand monitoring in the office. ■ Proposal: LoRa wireless *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The customer has six outdoor silos within the factory for storing raw materials, and they expressed a desire to continuously monitor the temperature and humidity data inside the silos as part of their raw material storage environmental management. Additionally, they wanted to record this data as quality evidence, but found that periodic inspections were inefficient and difficult to conduct. The distance to the office is 200 meters in a straight line, and considering the wiring work, the installation cost was a concern. In response, we proposed the "LoRa wireless device." We installed temperature and humidity sensors in the silos and input the analog signals into the wireless device. Since the six silos are located in the same area, we input the signals from each temperature and humidity sensor into the 8-point model HLR-A8. As a result, automatic data collection can now be performed at the IoT gateway in the office. [Case Overview] ■ Issues - They want to record quality evidence data, but periodic inspections are inefficient. - The distance to the office is 200 meters in a straight line, and considering the wiring work, the installation cost is a concern. ■ Request: They want to install sensors and collect data wirelessly. ■ Proposal: LoRa wireless device. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The customer was conducting two rounds of inspection of the pH meter located at the factory wastewater measurement site, once in the morning and once in the evening. However, with a decrease in factory personnel, there has been a demand for the automation of the inspection process. In the process of automation, the customer expressed a desire to monitor the pH measurement values in real-time and also to automate the recording of flow rates. In response, our company proposed the "LoRa wireless device." With this system configuration, we were able to address the customer's needs by enabling both "data collection and visualization via an IoT gateway at the main office" and "visualization with a bar graph meter (FDG) and abnormal notifications at the site office" within a single system, thus solving the customer's issues. [Case Overview] ■ Challenges - Automation of the inspection process was required - Desire to monitor pH measurement values in real-time - Visualization at the site office with a display device ■ Request: Build the entire system wirelessly and implement it at a low cost ■ Proposal: LoRa wireless device *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The customer needed to take immediate action in the wastewater treatment area of the factory in case of abnormalities, but they were troubled by the fact that they could not notice abnormalities without going to the site, and it was difficult to identify the cause since they did not know the data trends when abnormalities occurred. Therefore, we proposed the "LoRa wireless device" and also included a relay that can perform one-stage relaying. We enabled the wireless transmission of analog signals and contacts (abnormal signals) output from various water quality sensors at the wastewater treatment site, allowing for automatic data collection at the office's IoT gateway. [Case Overview] ■ Issues - Unable to notice abnormalities without going to the site - Difficult to identify the cause due to lack of data trends - Cost concerns when considering new wiring work ■ Request: Implementation of a system that can immediately notify in case of abnormalities and collect data wirelessly ■ Proposal: LoRa wireless device *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Are you facing any of these issues with "IoT implementation on-site" or "efficiency improvements in inspection and maintenance operations"? - In the past, I tried using wireless technology for data collection on-site, but the signal didn't reach without placing a relay… - Wiring work costs a lot of money… - The monthly fees for software and cloud services seem to be high for various reasons… By utilizing LoRa wireless devices, these issues can be resolved. - Long-distance communication of up to 5km is possible! - Since it's a wireless device, there are no wiring installation costs! For wiring over approximately 50m, LoRa wireless devices are more cost-effective! - There are no monthly fees since it doesn't use the cloud! You can operate with just the initial investment! Since its release in 2018, many customers, from large manufacturing companies to medium and small factories, have been utilizing this technology. In this "LoRa Wireless Device Proposal Case Collection," we present not only the product lineup but also 20 actual proposal cases using LoRa wireless devices for power monitoring, operational monitoring, and anomaly monitoring!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The LoRa wireless analog single output model HLR-A1-OUT can be used in conjunction with the HLR-A1 to output data transmitted wirelessly via LoRa from the HLR-A1 as an analog signal. This allows for the display of data from remote locations on PLCs or displays without the need for additional software. The wireless communication utilizes LoRa, which is one of the wireless technologies for IoT. As a result, it can communicate up to a maximum line-of-sight distance of 5 km to the parent IoT gateway HLR-GW, enabling wireless connectivity in locations that would have required a relay station with conventional 920 MHz band specific low-power wireless systems. This has been well received by customers. Note: This device is used with LoRa Private.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The LoRa wireless device RS-485 communication model HLR-RS485 converts RS-485 communication (Modbus compliant) into LoRa wireless communication, enabling data transmission to a higher-level system via wireless communication. Additionally, by using this device in wireless transmission mode in pairs, it is possible to wirelessly transmit RS-485 (Modbus compliant) signals via LoRa and convert the received signals back to RS-485 for connection to devices such as PLCs. The wireless communication utilizes LoRa, which is one of the wireless technologies for IoT. Therefore, it allows for communication over a maximum line-of-sight distance of 5 km between the parent IoT gateway HLR-GW and the paired HLR-RS485 in wireless transmission mode. This means that wireless communication can reach locations that previously required repeaters with conventional 920 MHz band specific low-power wireless systems, earning positive feedback from customers. * This device is used with LoRa Private.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The LoRa radio device HLR-C2 is a model that can perform input and output of two contact points with a single unit, enabling data transmission to an IoT gateway via LoRa wireless communication. Additionally, by using the wireless transmission mode function, it is possible to transmit contact input signals to the HLR-C2 via LoRa wireless and output contact signals from the HLR-C2 located far away. This function also allows for the simultaneous transmission of contact input signals from one HLR-C2 to multiple devices (up to 50 units) via LoRa wireless. The wireless communication utilizes LoRa, which is one of the wireless technologies for IoT. Therefore, it is possible to communicate up to 5 km in line of sight between the parent IoT gateway HLR-GW and the paired HLR-C2 in wireless transmission mode. This allows for wireless communication in locations where traditional 920MHz band specific low-power wireless would not reach without a relay, which has been well received by customers. * This device is used with LoRa Private.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The LoRa wireless device, the HLR-C1 model with one contact point, can perform input and output of one contact point with a single unit and transmit data to an IoT gateway via LoRa wireless communication. Additionally, by using the wireless transmission mode function, the HLR-C1 can transmit contact input signals to the HLR-C1 via LoRa wireless and output contact signals to a distant HLR-C1. This function also allows the contact input signals to one HLR-C1 to be transmitted simultaneously via LoRa wireless to multiple devices (up to 50 units). The wireless communication uses LoRa, which is one of the wireless technologies for IoT. Therefore, it is possible to communicate up to a maximum line-of-sight distance of 5 km between the parent IoT gateway HLR-GW and the corresponding HLR-C1 in wireless transmission mode. This means that wireless communication can reach areas where traditional 920 MHz band specific low-power wireless communication would have required a relay station, which has been well received by customers. * This device is used with LoRa Private.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The LoRa wireless device, the HLR-A1 analog single-point model, can input one analog signal and transmit data to an IoT gateway via LoRa wireless communication. Additionally, the HLR-A1 can be used in wireless transmission mode when combined with the HLR-A1-OUT. This feature allows the analog input signal from a single HLR-A1 to be transmitted simultaneously via LoRa wireless to multiple (up to 50) HLR-A1-OUT devices. For wireless communication, it uses LoRa, which is one of the wireless technologies for IoT. Therefore, it can communicate up to a maximum line-of-sight distance of 5 km to the parent IoT gateway, HLR-GW. This means that it can reach areas where traditional 920MHz band specific low-power wireless communication would have required a relay to reach, and it has been well received by customers. * This device is used with LoRa Private.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The LoRa radio multi-functional model HLR-A4C4 can perform 4 analog inputs, 4 contact inputs, and RS-485 (Modbus compliant) communication all in one device, allowing data transmission to an IoT gateway via LoRa wireless technology. For wireless communication, it uses LoRa, one of the wireless technologies for IoT. As a result, it can communicate up to a maximum line-of-sight distance of 5 km to the parent IoT gateway HLR-GW, enabling wireless connectivity in locations where traditional 920MHz band specific low-power radio would require a relay to reach. This has been well received by customers. * This device is used with LoRa Private.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The IoT gateway HLR-GW aggregates data from each LoRa radio and connects to a local PC via Ethernet or uses an existing LAN communication network to connect to a PC through a HUB, enabling data visualization. Data is stored in CSV format within the IoT gateway, and the stored CSV data can also be extracted using FTP. Additionally, it can be provided to external systems via Modbus/TCP communication. If the alarm upper and lower limits for analog signals or the alarm upper limit for contact signals are exceeded, it is also possible to output contact signals to lamps or buzzers from the IoT gateway (optional). For wireless communication, it uses LoRa, which is one of the wireless technologies for IoT. As a result, it can communicate up to a maximum line-of-sight distance of 5 km to the parent IoT gateway HLR-GW, allowing wireless communication in locations where conventional 920MHz band specific low-power wireless would require a relay to reach, which has been well received by customers. * This device is used with LoRa Private.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration