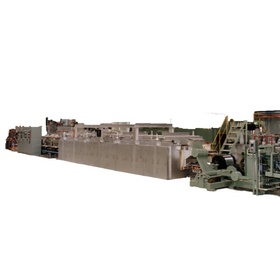

Batch-type heat treatment furnace "New High Shifter"

The bestselling heat treatment furnace "High Shifter" has evolved further with the latest features!

Born in 1954 as a full-fledged atmosphere heat treatment furnace, the "High Shifter" has received high praise in the automotive, bearing, machinery, and various other industries. Even now, it has delivered over 1,200 units as an energy-saving general-purpose heat treatment furnace that significantly shortens drying, heating, and seasoning times, and its demand is becoming increasingly diverse. Chugai Ro Co., Ltd. has significantly revamped various functions to meet these requests. The "New High Shifter" has achieved further evolution by pursuing ease of use, environmental improvements, and increased productivity. 【Features】 ■ Lower temperature of the furnace shell surface ■ Shortened cycle time due to increased combustion volume ■ Improved operability and maintainability ■ Reduced distortion of treated materials *For more details, please refer to the PDF document or feel free to contact us.

- 企業:中外炉工業

- 価格:Other

![Magnetic Field Heat Treatment Furnace 'HV-0.5TS' [Capable of High-Temperature Heat Treatment in a Magnetic Field]](https://image.www.ipros.com/public/product/image/ddb/2000754940/IPROS71798224619660191326.png?w=280&h=280)

![Stainless Steel Heat Treatment Furnace [Continuous Furnace]](https://image.www.ipros.com/public/product/image/0dd/2000667908/IPROS31215120885792288306.png?w=280&h=280)

![Stainless Steel Heat Treatment Furnace [Industrial Furnace]](https://image.www.ipros.com/public/product/image/7ab/2000667912/IPROS94572412093270665522.png?w=280&h=280)

![[Technical Column] Explanation of Types and Components of Heating Furnaces and Heating Methods](https://image.www.ipros.com/public/product/image/b51/2000729545/IPROS71443779370121838519.png?w=280&h=280)