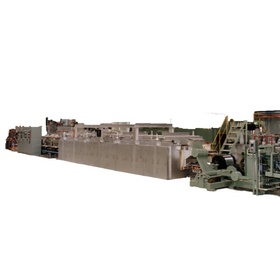

Introduction to Heat Treatment Furnaces

Leveraging our expertise in thermal utilization technology, we will accommodate various types of heat treatment furnaces.

We will propose the optimal furnace based on the type of work and heating conditions. We accommodate various methods (direct heating, indirect heating / continuous, batch / electric, gas, hybrid). So far, we have accumulated numerous achievements in the high-temperature fields of various industries, including automotive parts, aluminum castings, iron, and non-ferrous metals. We propose energy-saving, low-carbon, and decarbonization technologies that consider the environment! - Hybrid heating using electricity and gas - Waste heat recovery using heat exchangers - Waste heat recovery gas burners - Low NOx gas burners - Optimal control of air-fuel ratio - High-efficiency electric heaters

- Company:正英製作所 本社、東京支店、名古屋営業所、大阪支店、広島支店、九州支店

- Price:Other

![Stainless Steel Heat Treatment Furnace [Continuous Furnace]](https://image.www.ipros.com/public/product/image/0dd/2000667908/IPROS31215120885792288306.png?w=280&h=280)