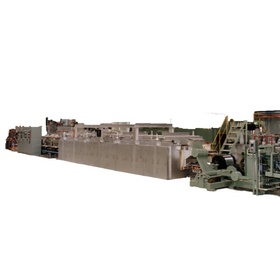

Aluminum heat treatment furnace

Compatible with AMS standards (American Aerospace Heat Treatment Standards)! We handle batch continuous furnaces.

The "aluminum heat treatment furnace" can achieve a precise temperature distribution. Aluminum is a lightweight, strong, and corrosion-resistant metal with excellent properties such as good conductivity of electricity and heat. However, these properties can be enhanced through heat treatment. 【Features】 ■ Compliant with AMS standards (U.S. aerospace heat treatment standards) ■ Capable of achieving precise temperature distribution ■ Handling of batch continuous furnaces available *For more details, please refer to the PDF materials or feel free to contact us.

- Company:サンファーネス

- Price:Other

![Sintering furnace [Dedicated continuous furnace for MIM]](https://image.www.ipros.com/public/product/image/bd1/2000666275/IPROS19372128107640458136.jpeg?w=280&h=280)

![Stainless Steel Heat Treatment Furnace [Continuous Furnace]](https://image.www.ipros.com/public/product/image/0dd/2000667908/IPROS31215120885792288306.png?w=280&h=280)

![[Technical Column] What is Bright Annealing? A Detailed Explanation of Its Differences from Atmosphere Annealing and Its Applications](https://image.www.ipros.com/public/product/image/88b/2000750776/IPROS48557069309752490217.png?w=280&h=280)

![[Case Study] Adopted for the processing of alumina ceramics: "Trolley-type combustion furnace"](https://image.www.ipros.com/public/product/image/fae/2000761045/IPROS07524933188631881628.png?w=280&h=280)